by Nick Drew | Fri 26 Apr 2024

Getting Attached with Holp

Today I will be travelling back from Paris having attended Intermat, so I thought I would schedule another look back at a previous article I did for Earthmovers last year, featuring our visit to Holp GmbH in Germany, unedited and featuring alternative photos and video footage.

Based in the glorious surroundings of Murrhardt some 40 km northeast of Stuttgart in Germany, family-owned business Holp GmbH was founded by Franz Holp in 1979, as an earthmoving and civil engineering contractor specializing in road building.

In 1990 Franz Holp was joined by his son Günter as an excavator operator, who had some great ideas for expanding the business. It was around this time that they invented a special multi-purpose trench/drag bucket, specifically for use on their own projects, which was later to become patented as the VarioLöffel aka Vario Bucket which was officially launched in 1998. The idea behind this bucket, was to enable them to speed up ditching and ditch cleaning and to be faster on the jobsite than any of their competitors.

In 1992 the company decided to look further into manufacturing attachments. Around this time Günter Holp made a visit to Sweden to a manufacturer to look at a tiltrotator which he duly purchased and once back in Germany he put it onto a machine to work with their VarioLöffel bucket, not long afterwards while using this bucket cleaning ditches in the forest, Günter noticed that one of the hydraulic tilt cylinders had cracked.

As no spares were available to repair the unit, he fixed it with a metal rod which effectively eliminated the tilt function and simply worked with rotation, the longer this went on, the more he realized that he really didn’t need the tilt function on most jobs.

He then went back to Sweden and said to them, “I would like to buy 50 rotators, I will sell them in Germany, but I need a big difference, I require a rotary joint that can take a lot of oil flow through it, because in Germany, we want to use oil hungry attachments like hammers and mulchers and so the oil should not get too hot”. This idea was dismissed by the Swedes at the time as not being possible.

So, Günter then entered a period of product development, refining his own concept and eventually in 2007, they launched the product to market as the RotoTop, a much simpler and cost-effective way to achieve 3-D movement of the bucket by using rotation only and the basic kinematics of the excavator itself, with very minimal loss of performance without a tilt function. It is also said that using just rotation, operators learn to use the attachments very quickly and find it a lot less complicated to use than a full blown tiltrotator.

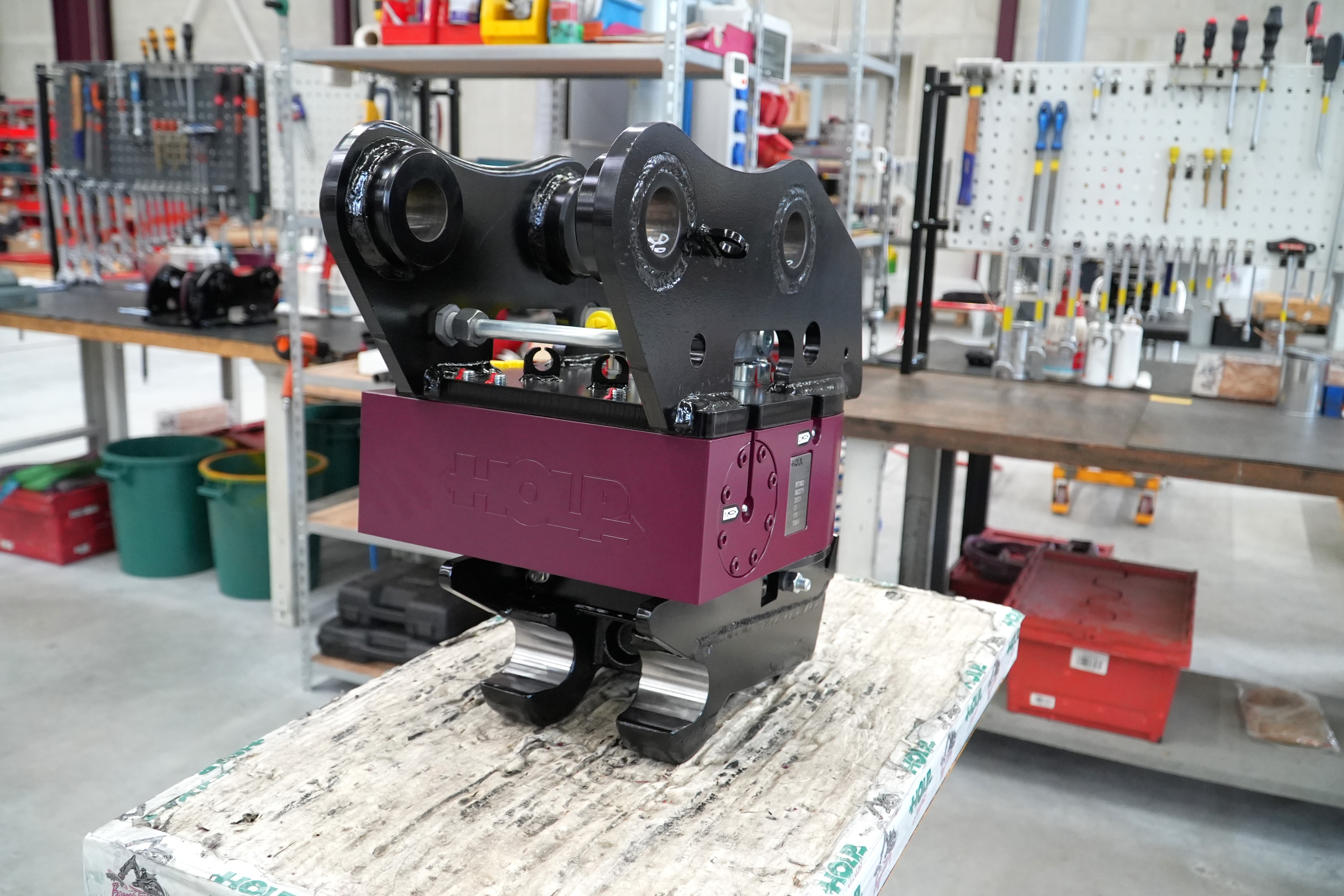

In addition to that, the strong and well-engineered RotoTop doesn’t require all the complicated electrics, that as we know, can cause issues on the regular tiltrotator attachments. Strength and simplicity are the key to this product as we were to discover later on at the demo area.

The company is currently producing 11 models in the RotoTop range from 600kgs to 45-tonnes, using only top-quality rotation drives, in a compact and robust housing, where the hydraulic motor and all associated pipework is well protected.

Holp had long outgrown their existing factory, and had started to build its much larger replacement in the summer of 2021, right in the middle of the Corona crisis, and moved in to the state-of-the-art facility between August and November 2023.

The building which has been a 7million euros investment, has around 4,100 square metres of floor space for production and stock storage, while around 400 square metres are dedicated to office space, kitchen and canteen areas. Around 80-100 employees will be working from this new facility.

The most striking part for me is the front entrance and the office area which has been designed and built to emulate the shape of the RotoTop, the finishing touches were still to take place at the time of my visit, but when fully finished it will become an iconic local landmark.

During a tour around the brand-new building, it was clear to see that the RotoTop product is really built to last. And what struck me was the simplicity of the design. Torsten Schick, Holp’s Executive Sales Director was keen to point out that a long product life is guaranteed thanks in part to the tool system’s sealings and the greased worm gear.

According to Holp the RotoTop features the largest, 5, 6 or 8-way rotary joints available on the market offering line-cross sections of up to 1 ¼ inches to allow for a maximum power output at 400bar for each excavator size class. This enables the best flow of oil to run attachments without any noticeable loss. The preferred 8-way rotary joint can be fitted on machines from 3.5-tonne up to 45-tonnes.

Another truly unique feature is the RotoTop’s power transmission through the gearing and not via the housing. Power thus goes directly to the bearing via the mounting plate and is absorbed by the bolts. This built-in design enables cost-effective overhauling of the RotoTop unit for a second or even a third excavator life cycle. So confident are they in the strength and longevity of these units, that they offer a 3-year or 3000 hours warranty.

Torsten said, “We have every confidence that the units can withstand long periods of extreme work applications, such as when running rock cutters, hydraulic hammers or vibratory compaction plates, they are extremely durable”.

But there is much more to Holp than just RotoTop, as we witnessed down at the company’s dedicated demo arena area where a dealer and customer event was taking place, with a variety of machines and attachments available for visitors to be able try out the equipment.

The company also produces the RotoX a modular, ram less, tiltrotator option for those who still feel the need for the full tilt and rotate functions.

There is also the MultiGrip bucket, a unique digging bucket that features two gripping talons on either side, enabling the operator to dig and grab items using the principles of an American style thumb. The uses are endless and only limited by the operator’s imagination or lack of it.

Another unique bucket is the BanketttLöffel, which just like the VarioLöffel, is made entirely with Hardox steel. This bucket is designed for verge clearance work in particular alongside and in between crash barriers, it has a removable open side to enable it to work under the barriers.

Being demonstrated on Holp’s very own Hitachi Zaxis 140W was the CutWheel, an attachment that looked like it had come out of a James Bond movie! This savage looking piece of kit is designed to cut small tress and shrubs from 3mm to 20cm in diameter, capable of working to a height of up to six metres it is controlled entirely from the operator’s cab.

One machine really caught my eye at the event, the Caterpillar 315CR in a stunning white and blue livery, which was an “all singing all dancing” example of this model, with two-piece boom, dozer blade, Trimble 3D machine control and of course a RotoTop rotation hitch.

I jumped in for spin on the controls, and having run tiltrotators in the past I very quickly felt at home with the RotoTop, naturally I found it to be a lot simpler and intuitive to use. It became apparent that what Günter Holp had said was actually very true, you can achieve most of what you need to do with just the rotation function, and the longer you use it the more it feels like a natural way of working, I shaped up the heap of stone the machine was sat on and was delighted with the experience I had while running the RotoTop, my only criticism being I felt the rotation speed was slightly slow, but I would imagine that could be tweaked if needed.

As the afternoon drew to a conclusion, we were invited up to some typically Bavarian local forestry land to witness a demonstration of the VarioLöffel (Vario Bucket) in action, once again mounted on Holp’s own Hitachi Zaxis 140W. The VarioLöffel is without doubt a unique attachment, and its when you see it being used in this application that you can really appreciate it.

Thanks to its variable design the bucket can be used in so many different ways when used in conjunction with the continuous 360o of the RotoTop. A V-shaped opening at one end is primarily designed for ditch cleaning, while the rectangular opening at the other end can be used for regular grading and excavation work.

Günter Holps record for ditch cleaning using the VarioLöffel is 666m per hour, in the forest where a lot of material like branches, mud and overspill from motor graders is lying in the ditches, using the drag bucket style in combination with standard excavation techniques. Most skilled operators should be able to manage about 400m per hour in the forest.

On a field road where only a bit of earth has to be taken out, meterage is about 1.5km per hour.

With the opening of the new factory, this family business is now entering a whole new chapter in its history, and there will be many interesting times ahead, of that I am certain.

We visited Holp GmbH, courtesy of my local dealership MPS Southwest Ltd and the Managing Director Jason McCullough, we would like to thank him for his hospitality during the visit.