by Nick Drew | Wed 02 Aug 2017

Tales of a tiltrotator trailblazer

After being a long time slow burner in the UK, the tiltrotator market is now on fire with the mainstream four brands Engcon, Rototilt, Steelwrist and SMP battling it out for market share, but thanks to my Swedish friend Robert Carlsson I recently discovered another smaller scale brand Maxbro.

Many of the major big Swedish players in the tiltrotator sector lay claim to being the founders of the concept and it seems to be a hotly contested debate about who came up with the original idea. According to the founder of MAXBRO, Rolf Mannbro he was one of the early pioneers, Rolf takes up the story, “In the seventies I was a machine operator at a power station, around that time I married the daughter of a contractor. Happy to have a machine operator in the family, my father in law bought a British built Hymac 580 hydraulic excavator. At the time I had no experience of excavating work and did not know the difference between a spade and a shovel, however I quickly picked up operating the machine and became skilled at it. During the course of my work I thought that the bucket mounting was so rigid and I kept thinking about ways this could be improved to make the machine more flexible, so I designed and fabricated the first concept to rotate the bucket, it was driven by a hydraulic motor, a planetary gear and a chain which I called Rotoplan and we went on to sell many of them”

In 1981 the Rotoplan design was patented in Sweden and in the United Kingdom and the company MAXBRO was also registered as a business. In 1985 another man Ulf Holmdahl patented a rotor with a worm drive and put a tilt on it, he named it Rototilt. The Rotoplan planetary gear and motor design was an obstacle for tilting so a 90° one-way tilt system was made. One of the benefits of that design was in comparison an extremely low additional height of only 40 mm, however only one unit was sold.

In 1981 the Rotoplan design was patented in Sweden and in the United Kingdom and the company MAXBRO was also registered as a business. In 1985 another man Ulf Holmdahl patented a rotor with a worm drive and put a tilt on it, he named it Rototilt. The Rotoplan planetary gear and motor design was an obstacle for tilting so a 90° one-way tilt system was made. One of the benefits of that design was in comparison an extremely low additional height of only 40 mm, however only one unit was sold.

In the early 1990’s several companies started to produce tiltrotators with all of them using Ulf’s worm gear Rototilt idea. MAXBRO owner Rolf decided to go for his own rotor construction using a slew ring with inside sprockets driven by one or two high torque motors. Rolf takes up the story,“The first tiltrotor with the new idea was fitted to a Volvo backhoe loader. The tilting cylinder construction was tight but turned out not to be powerful enough. However, the customer said that his loader was standing on icy ground while he was driving an auger which became trapped in the frozen ground and to his surprise the machine started to rotate around the auger! The customer was impressed with the rotation power and satisfied despite the weak tilt function”.

In the early 1990’s several companies started to produce tiltrotators with all of them using Ulf’s worm gear Rototilt idea. MAXBRO owner Rolf decided to go for his own rotor construction using a slew ring with inside sprockets driven by one or two high torque motors. Rolf takes up the story,“The first tiltrotor with the new idea was fitted to a Volvo backhoe loader. The tilting cylinder construction was tight but turned out not to be powerful enough. However, the customer said that his loader was standing on icy ground while he was driving an auger which became trapped in the frozen ground and to his surprise the machine started to rotate around the auger! The customer was impressed with the rotation power and satisfied despite the weak tilt function”.

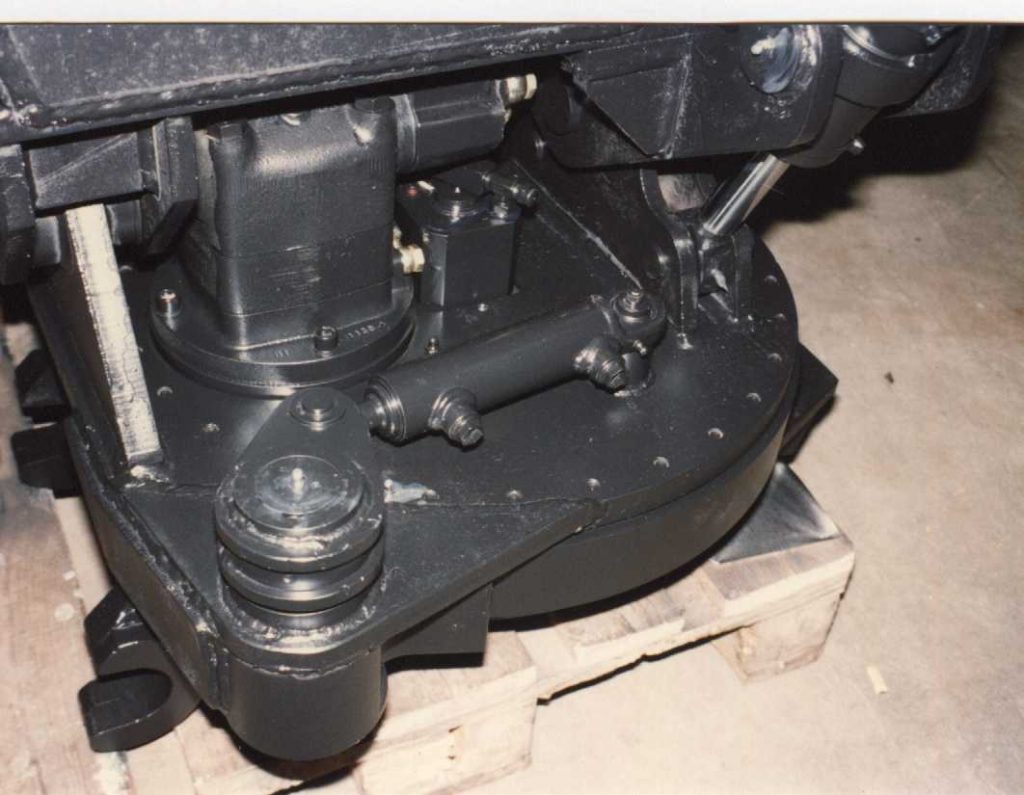

The next and current range of MAXBRO tiltrotators is branded and marketed as Joyroller. They feature two powerful high torque motors with integrated friction brakes and are available for machines from 12-24 tonnes.

The next and current range of MAXBRO tiltrotators is branded and marketed as Joyroller. They feature two powerful high torque motors with integrated friction brakes and are available for machines from 12-24 tonnes.

According to MAXBRO with a rotor output torque and braking action up to 20000Nm and rotating speed over 20 rpm it can rotate continuously as needed for example when driving a large diameter auger, winching logs or cables or wherever speed and power is needed. MAXBRO offer a choice of short and compact tilting cylinders, Powertilt or common tilt geometry with the safety locking of coupler corresponding to international standard ISO 13031.

According to MAXBRO with a rotor output torque and braking action up to 20000Nm and rotating speed over 20 rpm it can rotate continuously as needed for example when driving a large diameter auger, winching logs or cables or wherever speed and power is needed. MAXBRO offer a choice of short and compact tilting cylinders, Powertilt or common tilt geometry with the safety locking of coupler corresponding to international standard ISO 13031.

It would appear that Rolf is not adverse to building one off bespoke options, like we see in this video that features a Powertilt unit with 170 degree rotation.

The Digger Man Blog would like to thank Robert Carlsson for highlighting this topic to us and thanks to Rolf Mannbro for telling us about his history and development of his stand alone MAXBRO tiltrotator business.

It would appear that Rolf is not adverse to building one off bespoke options, like we see in this video that features a Powertilt unit with 170 degree rotation.

The Digger Man Blog would like to thank Robert Carlsson for highlighting this topic to us and thanks to Rolf Mannbro for telling us about his history and development of his stand alone MAXBRO tiltrotator business.