by Nick Drew | Mon 15 Aug 2016

Hire Spec Special

I'm often asked if my articles in the magazine are available online, well I thought it would be a good idea to bring some of them to the pages of the blog, which will enable people to share them via other social media platforms, starting with this one on the new JCB JS131LC.

The trend over the past decade which has seen machines becoming more and more technical in terms of engine technology to meet emissions regulations shows no signs of ending, but many end users I speak to see it all as an added complication and ultimately more hassle when using such sensitive fuel systems out in the real world and not on some sanitized testing ground.

Many hanker for the return of more simple machines without the need for any complex diesel particulate filters (DPF), selective catalytic reduction (SCR) or for that matter any form of exhaust treatment. This is especially the case for the large self-drive plant hire firms where by the nature of the game, machines often end up in the hands of less experienced operators who although qualified with the necessary tickets are not always up to speed with what is required to keep the machine running smoothly and trouble free.

Last year another manufacturing giant launched a 13 tonne class hydraulic excavator which is powered by a 70hp (52kw) engine, that requires no AdBlue and uses a simple single hydraulic pump design. That machine has proven to be extremely popular thanks in part to its simplicity and end user friendliness.

Now to further meet the needs of the rental sector Staffordshire based manufacturer JCB has launched its own brand new hire spec special 13 tonner the JS131. Based on the well proven JS130 model this machine takes its power from JCB’s own EcoMax engine which offers a power output rating of 74hp (55kw) running at just 1800rpm and which meets Tier 4F/IIIB emission standards without the aforementioned DPF, SCR, or AdBlue exhaust treatment. According to JCB this engine offers a 10% fuel improvement compared to competitive machines and with no need to use AdBlue a further 10% reduction in operating costs.

Now to further meet the needs of the rental sector Staffordshire based manufacturer JCB has launched its own brand new hire spec special 13 tonner the JS131. Based on the well proven JS130 model this machine takes its power from JCB’s own EcoMax engine which offers a power output rating of 74hp (55kw) running at just 1800rpm and which meets Tier 4F/IIIB emission standards without the aforementioned DPF, SCR, or AdBlue exhaust treatment. According to JCB this engine offers a 10% fuel improvement compared to competitive machines and with no need to use AdBlue a further 10% reduction in operating costs.

This machine uses the tried and tested Kawasaki hydraulic pump, all be it a slightly smaller version to the one fitted to the 81kw powered JS130, which has been fine tuned to perform with the 55kw engines output, offering improved power, productivity and fuel economy. The lower rated engine also runs a lot quieter with a gentle purr of just 99dB, which is down 2dB from the 101dB on the JS130, making the machine ideal for working on inner city jobs and housing sites, especially on those where residents have moved in while construction continues around them as is often the case.

This machine uses the tried and tested Kawasaki hydraulic pump, all be it a slightly smaller version to the one fitted to the 81kw powered JS130, which has been fine tuned to perform with the 55kw engines output, offering improved power, productivity and fuel economy. The lower rated engine also runs a lot quieter with a gentle purr of just 99dB, which is down 2dB from the 101dB on the JS130, making the machine ideal for working on inner city jobs and housing sites, especially on those where residents have moved in while construction continues around them as is often the case.

Other proven components in common with the JS130 and JS145 model include the slew motor by KYB-Bonfiglioli, track motors by Nabtesco and Kayaba valve blocks.

We got hands on with the new model at JCB’s Quarry, where we were able to take a closer look at the machine. Walking around the JS131 you could easily be mistaken for thinking it’s just another JS130 with a different model number sticker on it, but as is often the case it’s under the skin that the real changes have been made.

At first glance we notice that this “new” model does not feature the latest offside access route that is now fitted to full Stage 4 emission compliant JS excavators. In addition there is no need for the fitment of an AdBlue tank on the offside, so the machine is as they were previously so as to speak. This means access to the bonnet area is via the old traditional route, up and over the extensive tool box compartment which makes a welcome return. Hand rails on the left and on this machine fall from height (boxing ring) protection guides the operator up to the upper-structure for daily, oil, water and fan belt checks.

Other proven components in common with the JS130 and JS145 model include the slew motor by KYB-Bonfiglioli, track motors by Nabtesco and Kayaba valve blocks.

We got hands on with the new model at JCB’s Quarry, where we were able to take a closer look at the machine. Walking around the JS131 you could easily be mistaken for thinking it’s just another JS130 with a different model number sticker on it, but as is often the case it’s under the skin that the real changes have been made.

At first glance we notice that this “new” model does not feature the latest offside access route that is now fitted to full Stage 4 emission compliant JS excavators. In addition there is no need for the fitment of an AdBlue tank on the offside, so the machine is as they were previously so as to speak. This means access to the bonnet area is via the old traditional route, up and over the extensive tool box compartment which makes a welcome return. Hand rails on the left and on this machine fall from height (boxing ring) protection guides the operator up to the upper-structure for daily, oil, water and fan belt checks.

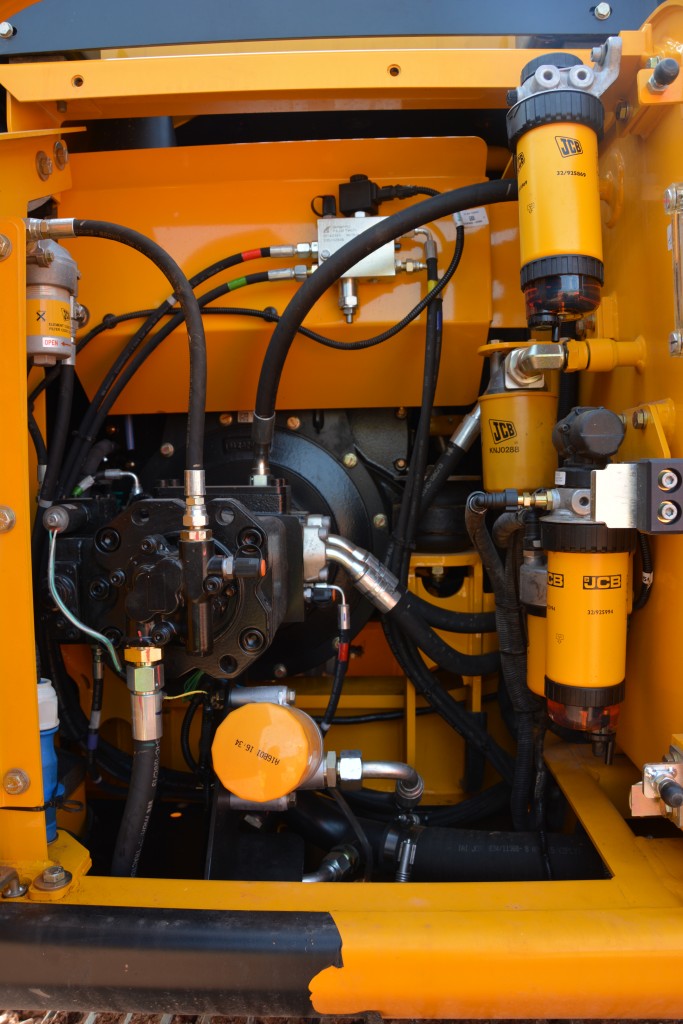

On the offside rear it’s the usual fair behind the rear panel door which is home to the aforementioned Kawasaki hydraulic pumps and ground level access to all the fluid filters. The counterweight with its striking black livery is home to the machines rear view camera and on this example was also home to an optional rear facing LED light which would be excellent for illuminating behind the machine during hours of darkness and still facilitating good vision to the rear for the operator from the monitor inside the cab. How many times have you been finishing off a concrete pour late on a winters night and you slew away to get the next bucketful only to plunge the groundworkers into total darkness, I know I have on many occasions.

On the offside rear it’s the usual fair behind the rear panel door which is home to the aforementioned Kawasaki hydraulic pumps and ground level access to all the fluid filters. The counterweight with its striking black livery is home to the machines rear view camera and on this example was also home to an optional rear facing LED light which would be excellent for illuminating behind the machine during hours of darkness and still facilitating good vision to the rear for the operator from the monitor inside the cab. How many times have you been finishing off a concrete pour late on a winters night and you slew away to get the next bucketful only to plunge the groundworkers into total darkness, I know I have on many occasions.

On the nearside rear we find the cooling packs, battery, air filter and the main isolation switch. Down below we see the standard JCB X frame style undercarriage with running gear from Berco including 7 lower rollers and an improvement compared to competitive machines in this class, 2 top rollers which I much prefer to see, as it helps to prevent track slack/bounce on the chain when carried over the 2 rollers. This machine was fitted with the standard UK spec 700mm triple grouser track pads.

On the nearside rear we find the cooling packs, battery, air filter and the main isolation switch. Down below we see the standard JCB X frame style undercarriage with running gear from Berco including 7 lower rollers and an improvement compared to competitive machines in this class, 2 top rollers which I much prefer to see, as it helps to prevent track slack/bounce on the chain when carried over the 2 rollers. This machine was fitted with the standard UK spec 700mm triple grouser track pads.

Climbing into the cab and it’s the usual standard we have come to expect from JCB. There are no cut backs in quality in this plant hire spec machine. You get a “full on” cab which also features the same dedicated full colour 7 inch multi-function monitor and all the other features you would expect to see in the JS130 and JS145 models. The only annoying thing once again is that there is no air conditioning as standard in this machine, for those who want it, and who wouldn’t in this day and age, you will have to specify the machine in its Plus Pack specification.

Climbing into the cab and it’s the usual standard we have come to expect from JCB. There are no cut backs in quality in this plant hire spec machine. You get a “full on” cab which also features the same dedicated full colour 7 inch multi-function monitor and all the other features you would expect to see in the JS130 and JS145 models. The only annoying thing once again is that there is no air conditioning as standard in this machine, for those who want it, and who wouldn’t in this day and age, you will have to specify the machine in its Plus Pack specification.

To the rear there is a large parcel shelf to store your lunch bag, which I think would benefit from some “cargo netting” to hold things in place. The fully adjustable seat is comfortable and allows for operators of all sizes to get comfy for a long day ahead. There are also options to have heated or ventilated seats if required.

On the right hand side we find a bank of chunky rocker switches, ignition switch and rotary throttle dial and the “high power” selector button, to the right hand rear of the cab there is a handy cubby hole for storing a mobile phone, with a hole below it to allow a charging lead to be inserted into the 12v aux plug on the console.

To the rear there is a large parcel shelf to store your lunch bag, which I think would benefit from some “cargo netting” to hold things in place. The fully adjustable seat is comfortable and allows for operators of all sizes to get comfy for a long day ahead. There are also options to have heated or ventilated seats if required.

On the right hand side we find a bank of chunky rocker switches, ignition switch and rotary throttle dial and the “high power” selector button, to the right hand rear of the cab there is a handy cubby hole for storing a mobile phone, with a hole below it to allow a charging lead to be inserted into the 12v aux plug on the console.

To the front of the cab we get the standard JS range flat glass 70/30 screen split which allows the upper section to be stored up in the roof and the lower section can be removed and stored behind the seat close to the rear window. Decent sized track foot pedals with a good grip pattern on them are also a very welcome feature.

So what was the JS131 like to operate? I took to the controls to find out. As with all JS excavators this machine features JCB’s 2GO hydraulic isolation safety system, which requires the operator to not only lower the isolation lever, but also to press a button as a double check procedure before the machine will start.

To the front of the cab we get the standard JS range flat glass 70/30 screen split which allows the upper section to be stored up in the roof and the lower section can be removed and stored behind the seat close to the rear window. Decent sized track foot pedals with a good grip pattern on them are also a very welcome feature.

So what was the JS131 like to operate? I took to the controls to find out. As with all JS excavators this machine features JCB’s 2GO hydraulic isolation safety system, which requires the operator to not only lower the isolation lever, but also to press a button as a double check procedure before the machine will start.

On turning the key the machine defaults to its standard Eco mode, the first thing that struck me was just how quiet the machine is on tickover and to be honest even when working “flat out” you could easily hold a conversation with somebody stood right next to the machine. I set about excavating a bit of trench in the combination of clay and stone down in the quarry, I initially tried this in its Eco mode but straight away decided I wanted more speed and power so selected the H+ power mode via the button to the left of the rotary dial, this gave the machine an extra spring in its step and felt a lot more responsive in its movements. The machine had decent power in the dig but in the ground conditions with the bucket encountering the odd lump of rock one had to work at it on the odd occasion you found something a bit hard. One thing I did notice was a slower than normal boom lift speed which could catch you out if raising a full bucket to load a wagon, but no doubt that could be tweaked up for a faster response if needed.

On turning the key the machine defaults to its standard Eco mode, the first thing that struck me was just how quiet the machine is on tickover and to be honest even when working “flat out” you could easily hold a conversation with somebody stood right next to the machine. I set about excavating a bit of trench in the combination of clay and stone down in the quarry, I initially tried this in its Eco mode but straight away decided I wanted more speed and power so selected the H+ power mode via the button to the left of the rotary dial, this gave the machine an extra spring in its step and felt a lot more responsive in its movements. The machine had decent power in the dig but in the ground conditions with the bucket encountering the odd lump of rock one had to work at it on the odd occasion you found something a bit hard. One thing I did notice was a slower than normal boom lift speed which could catch you out if raising a full bucket to load a wagon, but no doubt that could be tweaked up for a faster response if needed.

I then preceded to backfill the trench and I must say, I defy anyone not to find the hydraulics on the JS silky smooth and very responsive to the touch, not too light and not too heavy in feel, in fact just perfect as far as I’m concerned.

I then preceded to backfill the trench and I must say, I defy anyone not to find the hydraulics on the JS silky smooth and very responsive to the touch, not too light and not too heavy in feel, in fact just perfect as far as I’m concerned.

I then took the machine across to a heap of material to check out its climbing ability, travelling across the site in the machines high speed tracking mode the JS131 was reaching a speed of 6.6 km/h, on approaching the ramp of the heap the machine’s auto-shift function cut in and we dropped down to a speed of 3.8 km/h, on feeling a bit of track slip, I in the time honoured way, opted to use the bucket and dipper to pull myself up and assist in my climb up to the summit. Once on top I sealed up the heap using the back of the bucket ahead of some approaching bad weather.

I then took the machine across to a heap of material to check out its climbing ability, travelling across the site in the machines high speed tracking mode the JS131 was reaching a speed of 6.6 km/h, on approaching the ramp of the heap the machine’s auto-shift function cut in and we dropped down to a speed of 3.8 km/h, on feeling a bit of track slip, I in the time honoured way, opted to use the bucket and dipper to pull myself up and assist in my climb up to the summit. Once on top I sealed up the heap using the back of the bucket ahead of some approaching bad weather.

So just where will the JS131 fit in on sites, well if you are looking for high production or are an owner operator then the JS130 or JS145 might just suit you better, but for general site work and plant hire, especially within the self-drive sector the JS131 could just fit the bill.

So just where will the JS131 fit in on sites, well if you are looking for high production or are an owner operator then the JS130 or JS145 might just suit you better, but for general site work and plant hire, especially within the self-drive sector the JS131 could just fit the bill.