MARKET GUIDE: Demolition attachments

Peter Anderson reviews the latest demolition attachments and recent developments in their UK supply chain

ARDEN EQUIPMENT

Founded in 1956 as a bucket manufacturer, over the years Arden Equipment’s product range has been extended to include a wide range of demolition and recycling attachments.

This French manufacturer has developed an integrated, factory-fitted water spraying system for demolition shears. Four nozzles fitted on the shear’s body deliver an accurate spraying pattern to the work area, no matter how the attachment is moved. They spraying pattern can be altered by changing the angle of the nozzles, or by fitting alternatives, depending on the requirements of the jobsite.

The highly pressurised water turns into a mist that is propelled several meters away, creating a large area of fog, to better capture airborne particles. All of this is possible thanks to the attachment’s rotating mechanism, that carries both hydraulic oil and water, without having to worry about external hoses while rotating the shear.

BPH ATTACHMENTS

Demolition attachment manufacturer LaBounty has recently appointed BPH Attachments, based at Billingshurst, as its nominated dealer for the United Kingdom and Ireland.

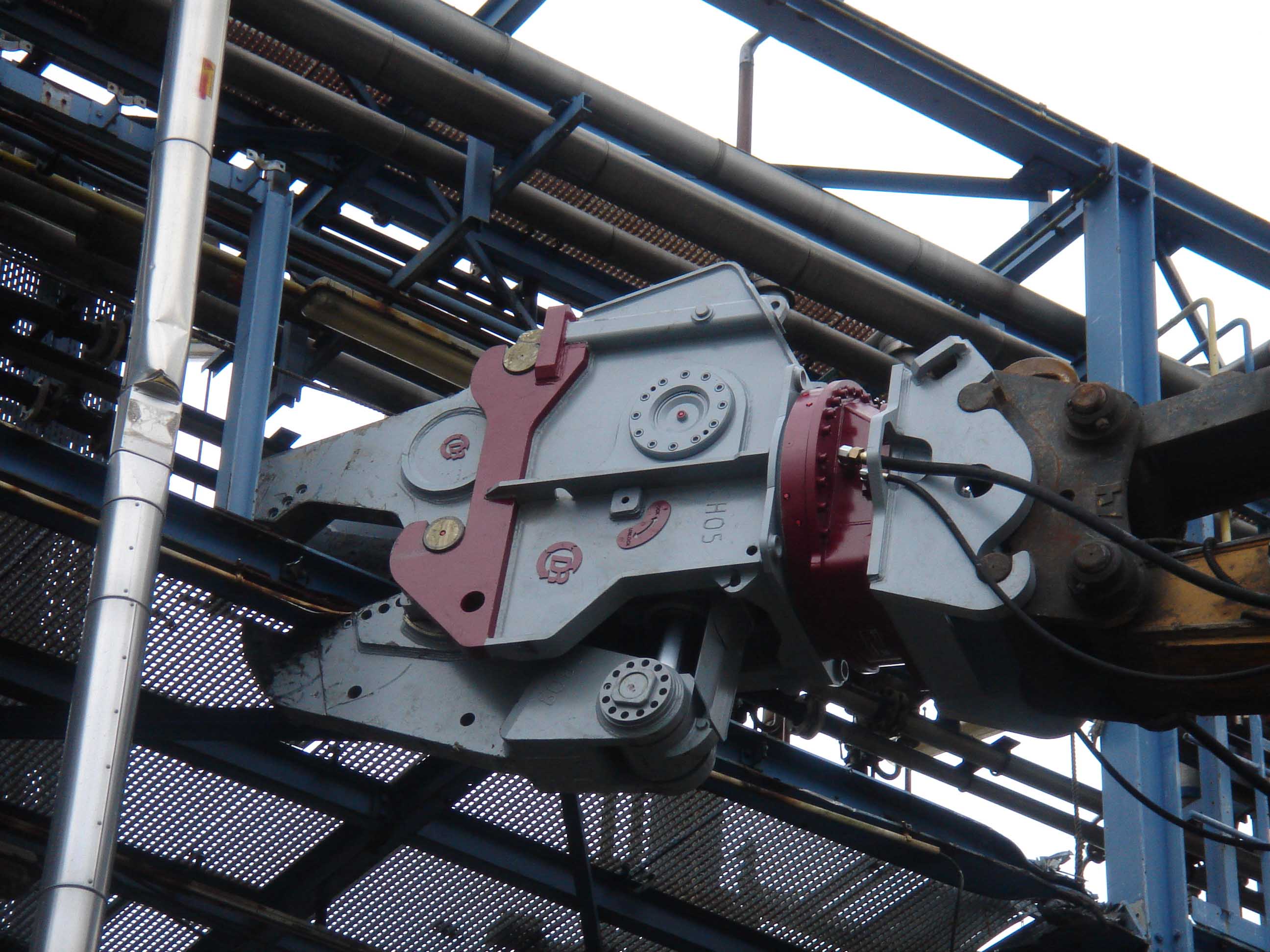

The main focus for BPH will be LaBounty’s MSD range of steel shears, which are said to be perfect for use in recycling and scrap metal processing, or on demolition sites. They feature wraparound, reversible saber piercing blades to reduce wear to the parent material, as well as minimising welding and maintenance.

Other features include heavy duty pivot components, an integrated speed valve to reduce cycle times, the dual guide pucks reduce upper jaw deflection, and a spin-on piston design adds strength to resist pressure spikes.

In addition, BPH also distributes the distinctive purple-liveried Prodem range of demolition attachments. There are six rotating pulveriser models that can be mounted to excavators in the 4-tonne to 65-tonne weight category. The fixed version consists of six models which are suitable for fitment to excavators in the 7- to 49-tonne weight range. In addition, an impressive 24 model range of selector grabs are available for excavators from mircos right up to 200-tonners.

DIGBITS

Over 10 years and several generations of design, BAV Alligator crusher attachments, designed and built in the UK by Digbits, continues to prove it’s worth on compact job sites, particularly where slabs and walls need to be demolished, handled and crushed. The attachment can produce 0-100mm material for re-use general fill, or it can be used to reduce and re-size larger chunks before they are fed through a crushing plant to render down to finer type 1 style material.

Large diameter, heavy duty jaw pivot pins, with hardened, top-hat style bushings are said give years of trouble-free service. Replaceable tip teeth ensure fast, easy on-site maintenance can maintain optimum penetration and operating efficiency. Full Hardox 450 chassis and jaws give outstanding strength and wear resistance

This year the company has produced an upgraded range of their rotary selector grapples, which now feature full Hardox 450 wear plate for both chassis and shells. The units also have revised pivot pin systems and, for the first time, the option to substitute standard demolition and waste handling type shells for forestry style timber tines. Four models are available, covering excavators from 2.5 tonnes up to 16 tonnes.

ECY HAULMARK

A new range of demolition attachments manufactured by VTN Europe is being distributed in the UK by ECY Haulmark. Called the Plus Line, it comprises a selection of demolition products equipped with a booster device, which intensifies pressure for better performance during demolition applications. here are three models available suitable for excavators from 14- to 30-tonnes.

According to the Warrington-based company the booster system allows contractors to increase the power of the hydraulic cylinder by increasing the internal pressure compared to the input pressure. During the work cycle, when closing the jaw, the device starts automatically as the required force increases by increasing the pressure supplied by the operating machine, according to the booster ratio. Benefits are said to be increased cutting and crushing strength, faster work cycles, better fuel consumption and higher productivity.

ECY Haulmark offers the full range of the Italian manufacturers VTN demolition attachments, including pulverisers with a quick jaw change combi kit and various models of concrete processors.

EPIROC

The range of hydraulic demolition attachments available from Epiroc is one of the largest in the marketplace and covers the whole process from breaking and crushing to downsizing and sorting, The demolition attachments include concrete cutters, pulverisers, shears, grapples, and concrete busters. The attachments are marketed and serviced by dealers located throughout the UK.

Over the last couple of years, the company’s hydraulic Concrete Buster range has been significantly extended with two new models now offering seven sizes available suitable for carriers from 2 to 85 tonnes. Attachment weigh ranges from the 320kg CB350 model, up to the 7,400kg CB7500.

Offering impressive cracking forces of up to 190-tonnes, depending on the model, each is equipped with two independently moving jaws that eliminate displacement force, thus lowering stress levels. Cutting blades are both replaceable and reversible.

A feature on all CB Concrete Busters is 360-degree endless hydraulic rotation, which allows precise handling and optimal positioning. If the cutter grips the material at an oblique angle a built-in pressure relief valve allows a ‘self-acting movement’ that brings the cutter jaw into the ideal position. This valve effectively protects both the carrier and the cutter from potentially damaging reaction forces.

INDECO

In addition to its range of hydraulic hammers, Italian manufacturer Indeco also makes demolition attachments, including pulverisers, shears, multiprocessors and grabs. All the products are available from appointed dealers, or directly from Indeco UK at Winsford, Cheshire.

The range of fixed and rotating pulverisers are specifically designed to withstand high levels of pressure, wear and abrasion, suitable for excavators between 5 and 65 tonnes. The multiprocessors are designed for fitment to excavators in the 12- to 65-tonne category, while the multi-grabs are designed for fitment to excavators weighing 3 to 50 tonnes. Shear models are available for mounting on excavators in the 4t to 90t weight category

New shear models include the ISS 5/7, which has been developed for demolition companies using smaller carriers. This model can be used on 4-tonners and and upwards in boom-mounted configuration, or from 7-tonners in bucket-mounted configuration. It has four reversible and interchangeable cutters, an interchangeable guide blade and the latest generation piercing tip. The ISS 35/60 model has also been redesign, suitable for base excavators from 35 tonnes when mounted to the boom, or from 60-tonne carriers in bucket-mounted configuration.

INMALO

As the UK dealer for Mantovannibenne (MBI) demolition attachments, Inmalo offers the full range of products manufactured by this Italian company.

The big news is the launch of a new range of MBI Eagle III shears, designed for excavators from 20 to 150 tonnes. This latest version of what is a well-established, proven demolition attachment features larger cylinders that offer 25% to 30% more power, working at 380bar pressure, which MBI reckon is the best in this industry sector. Other improvements include a piercing tip redesign that is stronger and covers the jaw end. The jaws are now built from single steel sections for added strength and feature replaceable armoured Jaw plates.

Designed for primary demolition of heavily reinforced concrete structures, the MBI combi cutter range has the ability to cut large steel sections and crack heavy concrete. Models have interchangeable teeth/blades, a large jaw opening, a speed valve to boost productivity and are suitable for mounting on excavators in the 30- to 70-tonne weight category.

Other attachments in the range include GIDA hydraulic magnets, which require no electrical installation, designed for 10- to 50-tonne excavators. The MBI range also include rotating and fixed pulverisers, grapples, concrete crackers, and multi-processors.

KINSHOFER

German attachment manufacturer Kinshofer produces an extensive range of dedicated demolition attachments, including fixed and rotating pulverisers, combi shears, grapples, multi-quick processors and demolition shears, all sold through an impressive UK & Ireland dealer network.

One of the firm’s many success stories is the DXS range, claimed to be the strongest scrap shears on the market. Thanks to the patented DemaPower 2.0-cylinder technique developed by sister company and demolition specialist Demarec, the DXS scrap shear has the performance of shears equivalent to one or two sizes up. Two of these DemaPower cylinders are built into the DCC concrete crushers, which have been specifically developed for demolishing the thickest reinforced concrete, such as viaducts, quaysides, and heavy foundations.

The latest addition to the Kinshofer demolition portfolio is the new EcoLine DLP pulverisers for primary and secondary demolition. The EcoLine has been developed specially to have a competitive rotatable pulveriser in the market. It’s a completely new concept with mostly new exchangeable wear parts.

LDH ATTACHMENTS

A complete range of demolition attachments manufactured by Okada are sold and serviced in the UK by LDH Attachments.

The Borden, Hampshire-based company offers a four-model range of crusher/shears the latest in a line of steel cutting attachments from the Japanese manufacturer. These are suitable for excavators from 6 to 50 tonnes and weigh between 780kg and 3,630kg. All models feature hydraulic rotation as standard and are fitted with oversized slew bearings for durability. Design features include innovative curved blade design, for improved cutting performance, and a tooth at the end of the jaw to bend back RSJ beams during cutting.

The five-model range of fixed or rotating pulverisers are available for carriers from 10 to 50 tonnes. Among the features are a built-in oil flow speed valve which provides faster operation, a bolt-on tooth plate system option, wider jaw opening and a larger concrete crushing area while shell shaped wedges provide high concrete crushing ability.

Four models make up the primary crusher range offering service weights from 1.69 tonnes up to 7.41 tonnes. Like the pulverisers the crushers are fitted with an oil speed valve built into crusher cylinders. The short cast body shape makes for a lighter attachment, superior durability and are easy to operate.

MOLSON GROUP

Demolition attachments manufactured by US-based Genesis and NPK Europe are distributed in the UK by the Molson Group.

The latest addition to the Genesis range is the GDT590, the largest Razer demolition tool to date. Featuring a lightweight design, the GDT Razer range is optimised to fit on standard and most high-reach excavators. The new GDT590 is designed for a minimum excavator weight of 55 tonnes, smaller models in the range cover excavators from 20 tonnes upwards.

NPK offers over 10 product groups, covering more than 50 models for the demolition and construction industries. The company’s latest model is the DG-25 demolition grab which slots into the range between DG-20A and the DG-30A. The DG-25 comes with new designed arms, combined with the new style frame which is said to offer more stiffness and better protection.

As an option the grab can be supplied with a double rotation motor for heavy loading applications. The grab has an operating weight of 1.45 tonnes and is suitable for excavators from 16 to 26 tonnes.

MUTLEY PLANT SERVICE

Dutch manufacturer Demarec part of the Kinshofer Group, offers multi- quick processors, concrete crushers and a new DLP eco-line pulveriser range, all of which are distributed by Mutley Plant Service based at Aylesham in Kent.

There are four sizes of multi-quick processors (MQP) available, suitable for carriers between 18 and 65 tonnes. The range is equipped with the patented DemaPower 2.0 hydraulic system, which the company says provides 25% more power than standard. The DemaLink system allows the jaw set to be changed on site in less than 10 minutes.

The new DCC, two-cylinder concrete crusher range also incorporates the DemaPower 2.0 system, available to suit 14- to 80-tonne excavators. It is available in three configurations, either a standard build, or with exchangeable tips, shrouds and long cutting blades, or featuring exchangeable wear parts and standard cutting blades.

A new Demarec DLP Ecoline of dedicated rotating pulverisers is designed for mounting on carriers at the smaller end of the market, from 9 to 32 tonnes. This is a completely new concept with mostly new exchangeable wear parts including cutting blades, wear plates, scraper teeth and shrouds, which can all be changed on site.

NORTHERNTRACK

Northerntrack is the UK dealer for the extensive Hydraram range of premium demolition attachments, which includes hammers, crushers, combi cutters multiprocessors and the like.

Leeds-based Northerntrack has been manufacturing and supplying demolition and related attachments since 1990. They use the latest Autodesk 3D CAD software for the initial design of attachments. This allows for much greater flexibility in product design and offers the ability to make swift and simple changes, in order to accommodate any special customer requests, or for custom builds.

Fabrication and welding is carried out by skilled time-served welders, within well-equipped workshops that are also used to refurbish or repair attachments.

TDL EQUIPMENT

Italian demolition attachment manufacturer Promove recently appointed TDL Equipment as its UK dealer. The Tankersley, South Yorkshire-based company will distribute the entire range of Promove attachments, including hydraulic breakers, a new range of rotating pulverisers, selector grabs and other demolition equipment.

According to Promove, its new rotating pulverisers are the best solution when it comes to primary/secondary demolition and separation of concrete from rebar. The complete range is made up of six models to fit excavators from 6 tonnes up to 40.

All models are made entirely of Hardon 400 wear-resistant steel and are built as a single block between the body and the fixed jaw eliminating welds, which could cause weaknesses of the structure. They have a high breaking force and with wide jaw openings can grab more material while oversized pins guarantee the maximum possible crushing force. The pins are further protected by a system of bushings which guarantee minimum wear.

WORSLEY PLANT

Established in 1996 Worsley Plant has steadily grown its portfolio of demolition attachments, representing some of the leading UK and European manufacturers.

The Middlewich-based company became the exclusive UK dealer for the Dutch built Rotar range of demolition attachments in 2011. The latest Worsley product on offer is the new Rotar RCC concrete cutter which the company says is ideal for heavy primary demolition.

The RCC is equipped with two hydraulic cylinders with an integrated Ramplifier device. Once the RCC is facing heavy resistance, the device is activated and doubles the pressure up to 700bar instantly. Features include replaceable teeth, longer and adjustable cutting blades, two flanges to make the cutter easy to adjust and maintain.

For primary and secondary demolition, Worsley offers the new improved Rotar demolition pulveriser. This latest addition to the range incorporates a speed valve for faster cycle time, a cross mounted hydraulic cylinder for exceptional force and large diameter hoses, bores and pipes to reduce the return pressure and provide maximum cutting force. Four models are available for machines from 15 tonnes up to 70.

This article featured in the April 2022 issue of Earthmovers Magazine.

Have you thought about taking out a subscription to Earthmovers magazine?

Subscribe to the industry-leading construction machinery publication here.

- Earthmovers is packed with all the latest construction machinery news and information to keep you up-to-date with industry developments.

- Impartial in-depth reviews will ensure you buy the best whatever your budget

- First-hand experiences of genuine owners and operators

- On-site analysis of the latest products by industry experts

- Save on the newsstand price of 12/24 issues and receive your magazines direct to your address, usually before it’s in the shops!