by Nick Drew | Fri 10 Dec 2021

Ken’s Winter Machinery Tips

Its that time of the year again, with winter looming on the horizon once more, time for another check up with our own resident Mr Rule book, Kenneth Hatcher.

Kenneth Hatcher is very passionate about plant and machinery, he is “old school” and likes to see things done right and according to the manufacturer’s manual, so much so that he suggested we come up with this post on how to look after your machine during the winter months.

What follows is not a definitive summary of what should be done, but a brief round up of the most important aspects as Ken see’s them. Wherever possible, always park your machine on level ground overnight, so you can get a true reading when you check oil and water levels which should be done every morning or before each shift

Ensure that the correct oil is used, winter grade should be used and ensure anti-freeze is still suitable and changed if not, this should usually be done by the company’s fitters during regular servicing though.

Ken notes that he see’s a lot of guys these days starting a machine from cold and going straight to work flat out! This of course is not good practice and wherever possible you should always leave the machine running on low revs for at least 10 minutes in cold weather, even longer in cases of extreme cold. While the machine is warming up, it’s a good idea to get out and clean the dew or ice off the windows and mirrors, that’s primarily for your safety and that of others who maybe in the vicinity of the machine.

Some machines feature an auto warm up process and this should be adhered too, its there for a reason after all. Once engine warm up is complete you should cycle the hydraulics for a few minutes to warm up the oil. Its always best practice to fill the fuel tank at the end of the shift to prevent condensation forming in the tank

.

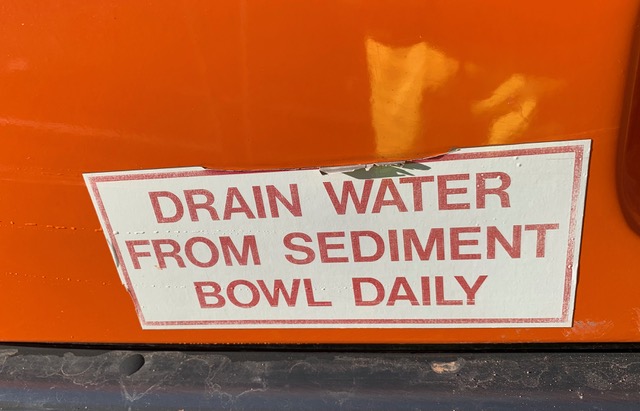

Try to find a dry level spot to park, not in a puddle or quagmire that might freeze overnight, remember even steel don’t like the cold. Always drain any water from the sediment bowl and the tank daily it can cause so much trouble and could freeze in extreme cold

At the end of the shift always allow a minimum of 3 minutes idling time to let the engine cool down slowly protecting the turbo, engine valves and the cylinder head. While the machine is cooling down it’s a good idea to clean out the track, easier said than done on UK sites for sure, but at least dig out around the top rollers wherever possible.

So there we have it, and the Digger Man Blog would like to thank Ken for his input into this blog post.