by Nick Drew | Wed 15 Jul 2020

Economy Excavating

We have witnessed in recent years, the rise of companies like LiuGong and Sany who have done well in the UK market. Both now have established facilities in Europe as part of their expansion programmes. There was also a brief appearance by another Chinese brand, Detank, but that disappeared as quickly as it came. We then saw Sunwards first appearance in the UK from a base in Essex, but that too quickly vanished.

The latest entrant to the UK market is the unlikely named Carter range of hydraulic excavators, which are manufactured by Shangdong Carter Heavy Industry Machinery Co Ltd in Linshu County, China.The company who started producing hydraulic excavators in 2000, claim to have a good name in the Chinese domestic market for reliability and quality.

The machines are being imported by Mathew Davies of Carmarthen based MD Plant Hire & Machinery Limited. Mathew had left school and gone straight into agricultural work and was later involved in working with tractors. In 2007 he decided to start doing plant hire, but as it progressed, like many, he had suffered long enough and decided it wasn’t for him. So, he turned to buying and selling plant and machinery, including second hand kit and new Indian built Solis tractors.

Mathew has just recently gone down the route of becoming an importer for the Carter range. Talking about this decision Mathew said “Carter had been looking for a UK based dealer for some time and they had approached us on a number of occasions. They had apparently been watching our activity on social media platforms promoting the Solis tractors, and that inspired them to get in touch with us”.

Mathew continued “We were really keen to be able to sell something alongside the tractors. I’ll be honest with you, I was a bit wary to start with, as you never quite know what your going to get from these companies. However, we did our research on them and we liked what we saw to be fair. Carter is not a massive concern by any stretch of the imagination, in fact they only employ around 50 employees at the factory. However, they suggest that the workers they have are the best of the best and at the top of their game”.

“We like to feel the machines are well-built and of good quality. It’s a bit old fashioned, but for instance, there is very minimal electrics on the Carters, which we find a lot of people like. In all honesty, we have had customers come to look at them and they have nearly all commented on the simplicity of the machines. As an example, everything up to 6-tonne has a manual throttle with a cable, something that is cheaply and easily fixed if it broke, not like some of the electric control dials that we see on a lot of the more well-known brands. In fact, one old school boy who came to see them said “why don’t they build machines like they used to”? He was then delighted to see how simple and straightforward these machines are”.

The lower weight machines all use well proven Yanmar engines, from 1.6-tonne up to 8.5-tonne, while the hydraulic pumps come from Italian manufacturer, Casappa, Rextroth Bosch, or the Japanese KYB brand. On the larger machines from 15-tonne up to the top of the range 46-tonne offering, Kawasaki is the preferred hydraulic pump option. Talking about components Mathew said “The hydraulic systems supplied with the Carter machines is very similar to other well-known brands and we feel the performance is on a par with them”.

“There is also more well-known componentry that goes into these machines. The booms and dipper arms for instance are supplied by Komatsu. And on the larger machines from 15-tonnes up, the undercarriage frames are all produced by Komatsu too, so in our opinion its all good gear. Take the idlers and track rollers on our 8-tonne offering for instance, they are exactly the same as you would find on an early Cat 308. Its probably fair to say that they are using parts that we may have seen on older machines, and then assembling them in the factory. I would say that its only around 15-16% of the product is actually built in-house, with the rest of the components being brought in for assembly”.

The machines are built very region specific. On the 6-tonner for instance, they do an option for either a fixed boom or an off-set boom arrangement. According to Mathew, this is because in places like Australia and Indonesia they just don’t want the off-set, preferring the centrally mounted fixed boom, citing issues of premature wear in the off-set configuration as the principal reasoning for opting for a fixed mount.

Talking about the CT85-9 Mathew said “Its possibly the only dedicated 8-tonner on the market with a fixed boom, which a lot of people we deal with hanker after, so I think this will be a good seller for us. As a second hand machine dealer, we find that buyers abroad will always go for the fixed boom machines like the old Hitachi EX60’s. They were bomb proof and very popular overseas, we feel this will be equally as good for sales”.

The Carter range which are all CE marked, actually starts with the sub-1-tonne CT08 model - a really basic machine with fixed track frame, powered by a single cylinder Yanmar engine. Prices are rarely quoted to me on such visits, but I was told that this machine will go with 3 x buckets and a semi-automatic quick hitch for just £5000 + VAT - ideal for the jobbing builder or landscaper who wants a cheap digger.

Above this in the range is the CT08S - a higher spec model with expanding tracks, a 3-cylinder Yanmar engine and Rexroth pump for around £8000 + Vat. There are 3 models from 1.6 to nearly 2-tonne, CT16-9, CT17-9 and CT18-9. The CT18-9 features a fully enclosed cabin, expanding tracks and boom off-set. The company are set to launch 2.5 and 2.8-tonne models but they are around 7 months away at the moment.The 4.5 tonne CT45-9, 6.5 tonne CT65-9, 8-tonne CT80-9 and slightly larger CT85-9 complete the mid-size range line up, with all machines taking power from Yanmar power units.

There is currently no 13/14 tonne offering in the Carter line up, but one may be added at a later date. From here the range jumps to a 16-tonne class CT150-9, followed by a number of 20 – 26 tonne offerings and the CT360-9 a 36-tonne machine. All are powered by Isuzu engines, which for 2020 will be Stage 5 emissions compliant. On machines produced up until December 2019 they would have been fitted with Stage 3B engines. The range is topped out with the 46 tonne CT460-9 which is powered by a Cummins unit.

The Carter heavy line bears a striking resemblance to Komatsu machines probably due to the fact they purchase components from the Japanese manufacturer.

Asked if he had any concerns about the build quality of the Carter machines Mathew said, “I’ve spoken to a lot of existing dealers across Europe, and they have all said that you really don’t need to worry once the digger goes out to the customer. Carter have been building them long enough to know what they are doing in terms of strength and durability, and by using well-proven components, all our machines are also CE marked for the European market. I will add that like all Chinese manufacturers, they do listen to our feedback and act on it accordingly”.

Having had a brief look around the 1.6 tonne offering, attention then turned to the 8-tonne offering the CT85-9. First impressions were that it looked to have some stylish bodywork with a rather old-fashioned looking cab, which reminded me of the early Sany SY75’s.

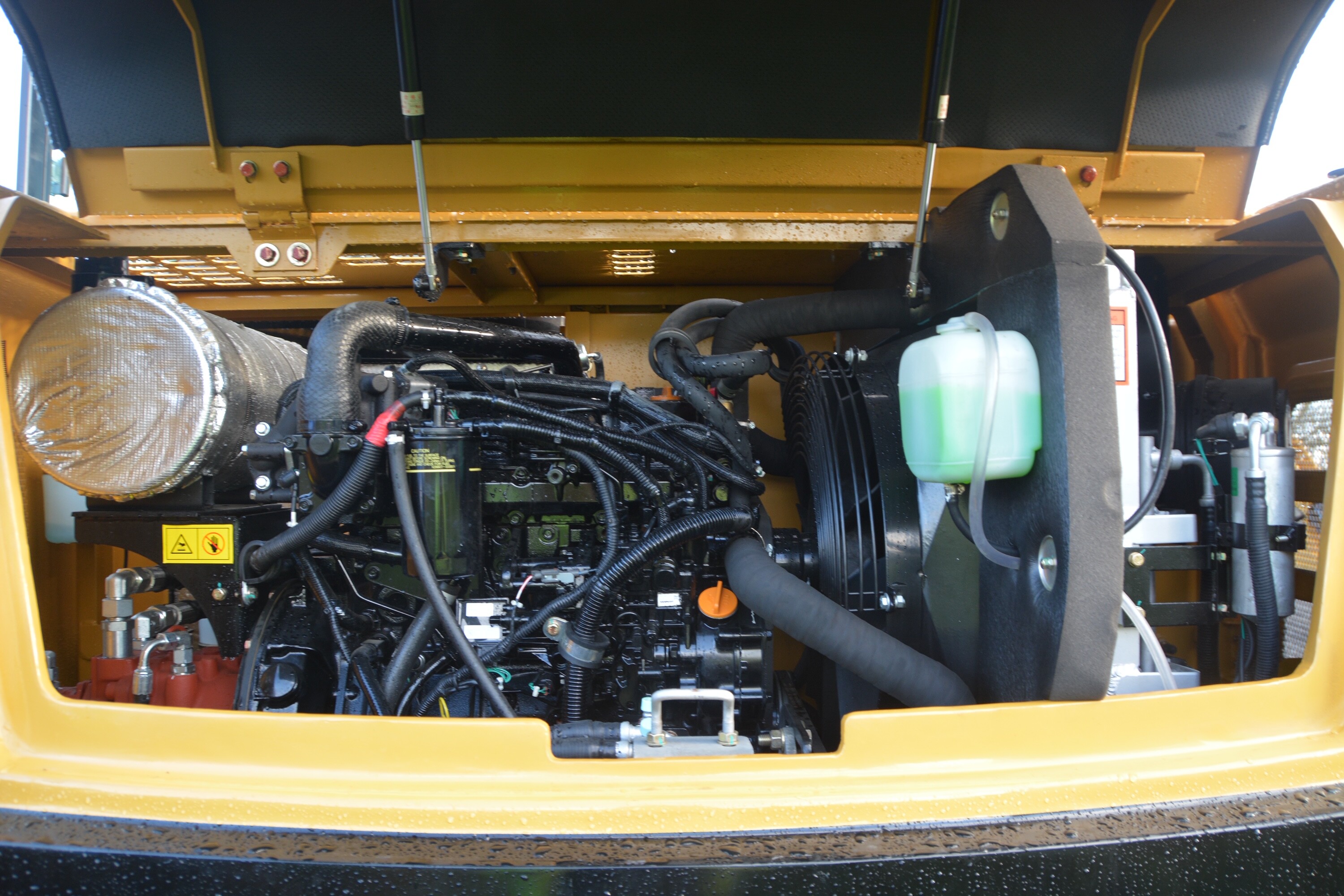

The 4-cylinder 56.5kw Yanmar 4TNV98T engine mounted in the back is accessible via a large lift up panel. I noted that unlike many, it is mounted with the hydraulic pump and exhaust on the near side right behind the cab, while the cooling pack is mounted across on the off-side of the machine. Would this have any impact on heat build up within the cab during a long shift I wondered, although having said that, it is mounted a fair way back in the bay. This is also home to the primary and main diesel filters and the standard size screen wash bottle.

Behind the offside panel is the aforementioned cooling pack, air filter housing, 12v battery and the hydraulic oil level sight tube, situated on the back of the 130-litre hydraulic oil tank.

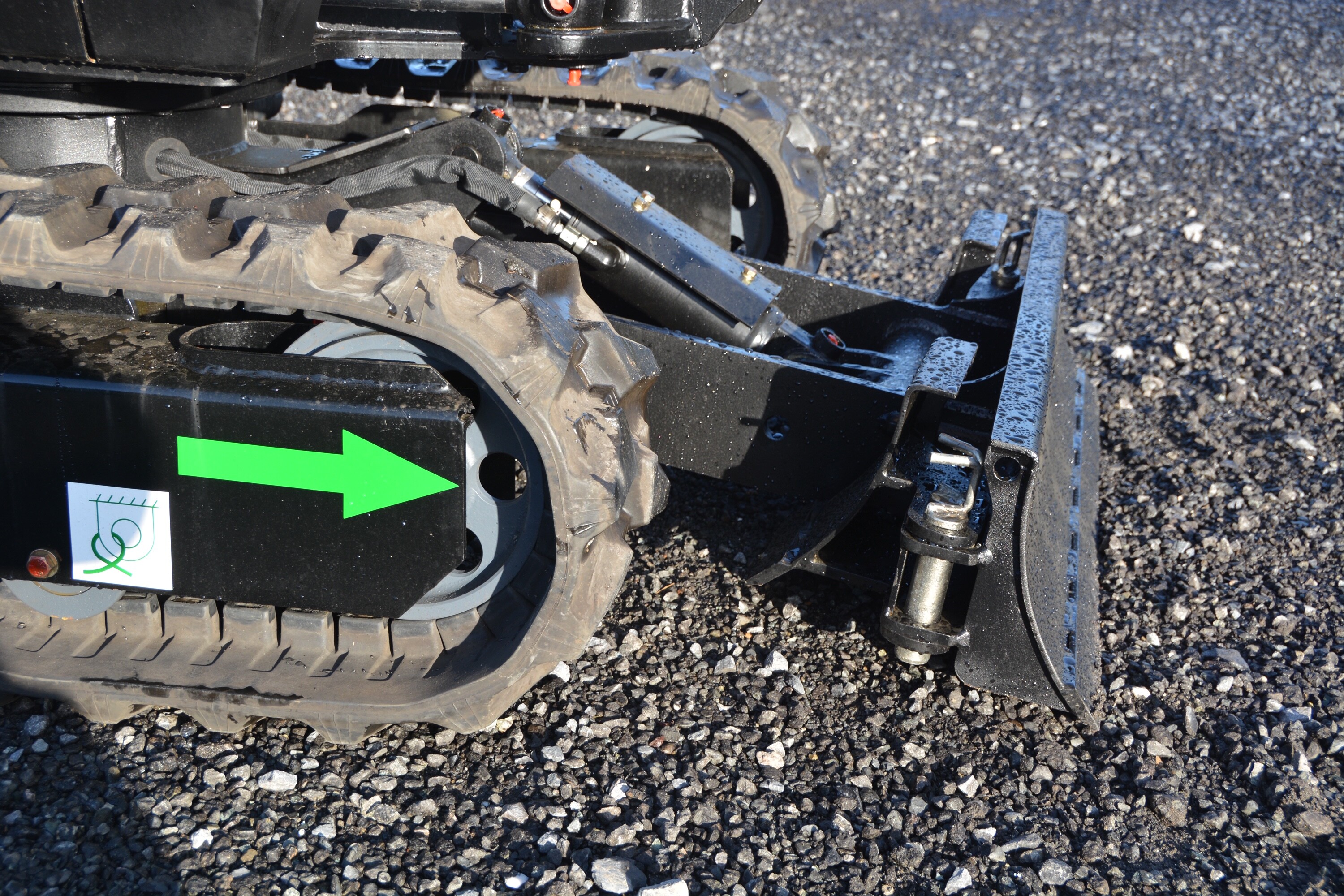

The track length is 2785mm and in all honesty is a bit on the short side, with the machine having a tailswing radius of 1870mm. It does look a bit odd with a lot of rear overhang, and it was something I noticed later when operating the machine. I feel this could be easily rectified by lengthening the track frame on future models.

The dipper arm is a bit on the short side too, but this is often preferred in Asian territories. However, for the UK market, I feel a longer option would be better suited. These machines are coming from China complete with a locally sourced hydraulic semi-automatic quick coupler which requires a pin to be put in when changing attachments. I would suggest checking on the legality of them before putting one to work.

Climbing into the cab you would have to say it was pretty spacious and it was nice to see that there is a significant parcel shelf in the back behind the seat for the operators grub bag. I’m not going to lie, inside they are pretty basic and dated in design, but you do get everything you would expect from this kind of machine. Simplicity is the key and on the right-hand side console, full air-conditioning is provided, a rotary throttle dial, dozer blade control lever and the ignition key. The left-hand side console is home to the radio which features a USB port, while alongside is a bank of five simple rocker switches, for wiper/screen wash, working lights, two speed tracking selection and the quick coupler switch.

A basic looking full colour monitor is provided offering the operator feedback on temperature and fuel level. There are also simple menus to scroll through to adjust flows for attachments if required.

I was invited to push and poke a bit of dirt around in Mathew’s yard, so a full test drive was not really possible. I did, however, manage to get a bit of a feel for this machine in the brief time I spent on it. The first thing I noticed was I found it difficult to get comfortable in the seat. I would probably have benefitted from having some time to adjust it properly, so it might have just been me.

I cranked up the throttle and dug in to grab a bucketful. The machine was supplied with Chinese buckets and I felt they were a bit on the large size for this machine. The extra weight of a full bucket and that track length issue seemed to unsettle it a bit and it became slightly “noddy” on the front end. Having said that the controls were pleasantly smooth and precise movements were easily achieved thanks to the quality of the Japanese hydraulic system.

The CT85-9 is a pretty lively beast with fast acting dipper and boom movements and plenty of poke in the dig. It’s not slow on the turn either, with a slew speed of 11rpm and a top tracking speed of 5.3km/h.

In summary I would say these machines are not going to appeal to everyone just yet, would I buy one, probably not, but for jobbing builders, landscapers and agricultural contractors, this is a great opportunity to purchase a relatively cheap digger that does just what it says on the tin. With the dealer offering this model with the hydraulic hitch and 3 buckets for just £37,995 + VAT plus the added peace of mind of 2 years warranty, there are going to be some who are attracted to a quick Chinese takeaway!