by Nick Drew | Sat 23 Apr 2022

E’s are Good!

The official launch took place early last month, and although I paid a visit to the first model to be delivered into the UK market, (as featured in the current edition of Earthmovers Magazine) I was not able to get any stick time on the machine, so when CASE offered me a chance to get “hands on” with the CX250E model, I jumped at the chance

CASE had promised us some big changes and they have not disappointed. Perhaps the most surprising change of all comes in the engine department, with the replacement of the Isuzu engines across the board in favour of the latest Stage 5 emissions compliant Fiat Powertrain Technologies (FPT) engines.

The CX130E, CX160E and CX180E models will continue to be fitted with a 4-cylinder engine.

But in the case of the CX210E and CX250E this now means a move to a super fuel efficient and powerful 6-cylinder, 6.7 litre, FPT NEF6 unit, which on the CX250E offers an increase in power output up to 133.4kw @2000rpm, compared to the 132.1kw on the old Isuzu power pack fitted in the D-Series.

The engines are fitted with FPT’s patented and well proven HI-eSCR2 after treatment technology, which thanks to its integrated SCR catalyst and PM (Particulate Matter) management system, and the use of AdBlue, eliminates the need for any often problematic, exhaust gas recirculation (EGR) system.

This simpler system is said to be completely maintenance free and to use the manufacturers words, built for-life. Talking of maintenance, CASE have doubled the service intervals on this range up to 1,000 hours for engine oil, fuel and oil filters which also helps to keep cost of ownership down.

In addition, with fuels costs going through the roof at the moment, the whole E-Series range can be run on alternative fuels such as HVO (hydrogenated vegetable oils).

Walking around the machine, at first glance one could be mistaken for thinking not much has changed, the same CASE tan and grey colour scheme and decals, but many of the changes are under the skin of these new machines. On closer inspection one notices some significant changes to the body work. The side panels now feature a new curved contour design, which continues around to the counterweight.

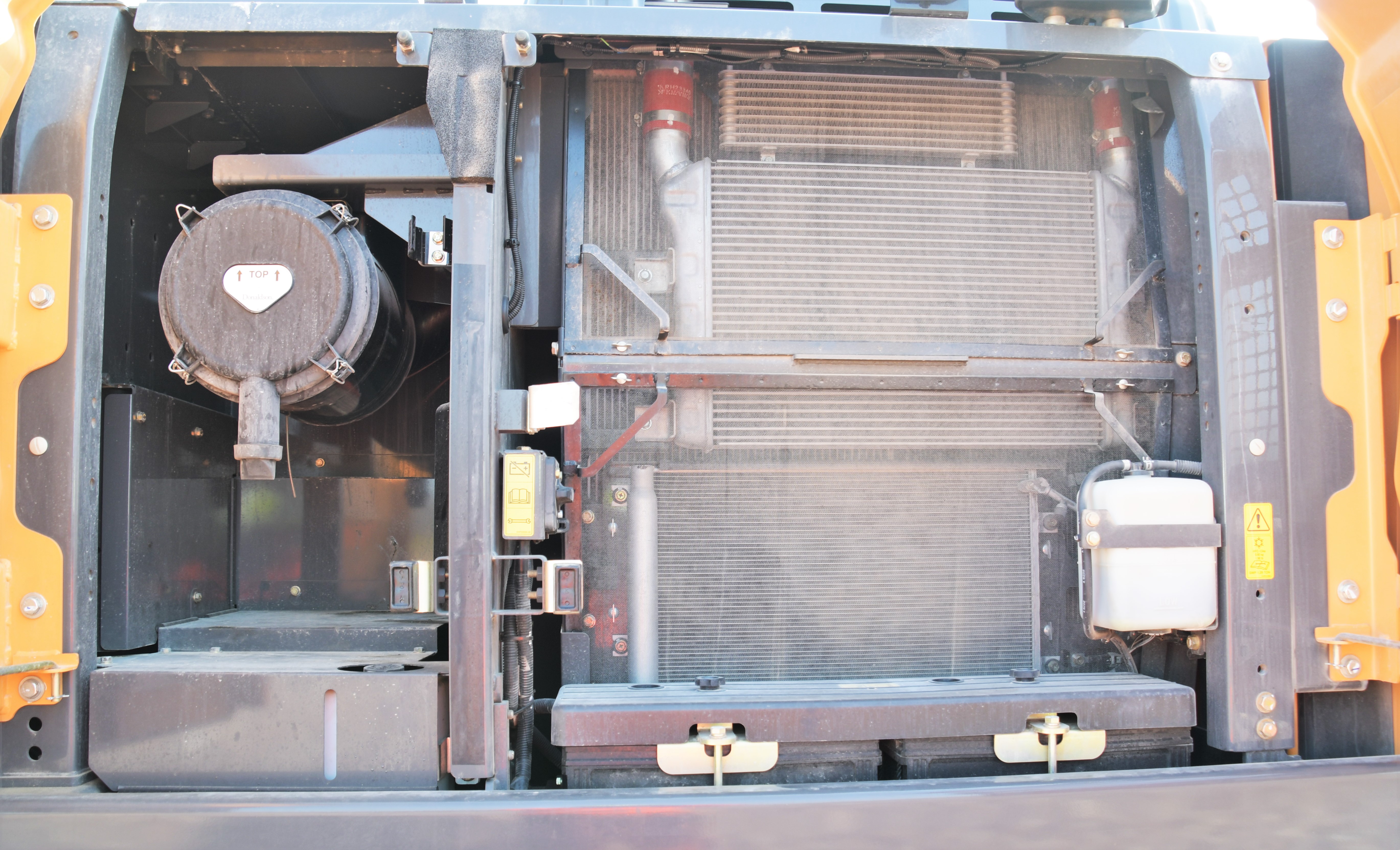

Behind those rear panels, it’s the usual fare, on the nearside behind the cab, twin panel doors open up to reveal the radiator cooling and air conditioning packs, a re-design in this area allows for the air conditioning radiator to be swung out to facilitate cleaning of the main radiator.

This area is also home to the air cleaner, batteries and coolant expansion bottle, in addition to some storage space for such things as cloth strops and other essential items like a box of grease tubes for example.

Down below, the undercarriage has been significantly redesigned, hidden inside, the recoil spring assembly which maintains the track tension, has been compacted in length and moved forward away from the front top roller. This enabled the designers to create a larger hole below the roller to allow more muck build up to drop down, while not potentially dropping straight down onto the track tensioner, which is now completely out of the way, this also helps to prevent premature wear of those top rollers.

In addition, the 8 bottom rollers have been repositioned in order to produce less vibration and to offer a much smoother ride when tracking around, something that happens a lot more these days on housing sites, as the excavators are often kitted out with a fork attachment to serve the bricklayers as opposed to having to hire in a forklift or telehandler, as someone who has previously had a lot of experience doing that job, I can really appreciate what a difference that will make to the machine, the operators comfort and the overall operation.

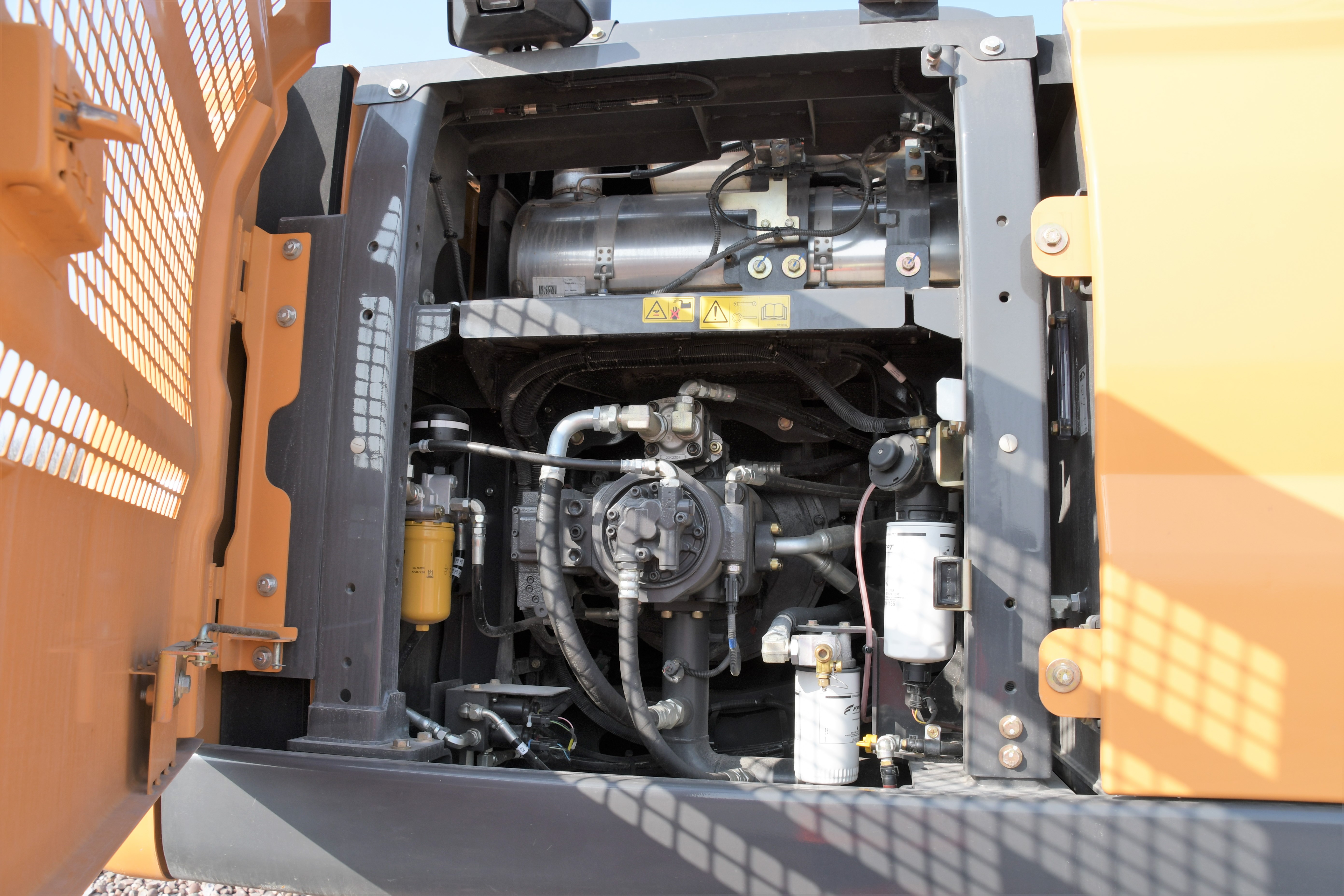

Behind the offside panel we find the now almost legendary Kawasaki hydraulic pump, which definitely appears to be becoming the benchmark in modern day hydraulic excavators. Also in this space, we find the oil and fuel filters, which once again, are all easily accessible from ground level for regular servicing.

At the off-side front, the first compartment that also forms the steps up to the engine bay, is home to the standard fitting electric refuelling pump, while above that, another panel opens outwards to reveal the 84 litre AdBlue tank, easily identified by its blue cap, and relatively easy to top up as required.

Hand rails are fitted to the left-hand side to guide the operator up towards the engine bay to facilitate easy daily maintenance.

Climbing into the cab is where I noticed the most changes, personally I have always found a CASE cab a nice place to spend my days previously, but it’s probably fair to say it was time for an upgrade. They have quite clearly listened to customers and operators alike to make the operator environment first class.

Dominating the cab interior is the all-new 10” monitor, which in common with many other manufacturers these days now resembles a tablet device and is a touch-screen affair. As I saw it the monitor is spilt into 3 defined sections, top of the screen is the icon area, which displays operational information such as machine hours, oil and water temperatures, fuel level, working modes and the time.

Below that and forming the largest part of the monitor is the camera views, which can be configured in a wide variety of ways to suit the operator’s preferences, there is even an option, if specified, to have the 270o “birds-eye” camera display on the screen, along with side a rear-images.

Below that is what they call the information area, which displays the air conditioning status, i.e., fan speed, vent selection and temperature.

More buttons are integrated at the bottom of the monitor for manual selection of the cameras, air-conditioning, fan speed, and temperature to name a few.

The whole thing is easy to navigate and very intuitive to use, anyone who is familiar with an iPad will instantly feel at home with this monitor, and each individual operator will be able to configure it to suit his own needs and operational preferences

The new air suspension seat which is standard, is now integrated with the joystick consoles, so the sticks rise and fall with the seat at all times ensuring that small or large operators always maintain their preferred and most comfortable operating position.

Elsewhere in the cab controls are quite minimal which means less clutter around the cab, on the operator’s right hand side console we find a bank of 6 switches, for track speed selection, attachment selection, lift alarm, working lights, wiper and screen wash button, these buttons are located around the throttle dial, which also acts as working mode selector.

Anyone who has operated a CASE CX excavator will be familiar with the throttle dial, on previous models there were basically three work mode settings, A, H, and SP.

On the E-Series, the machines now have 4 work modes + 10 throttle position settings. The new modes consist of SP (Super Power) this mode preferred by operators offers maximum power and productivity and the throttle is set at 10.

P (Power Mode) is effectively the replacement for the old H & A modes on the previous models, and in this setting the throttle can be set from 1 to 10.

E (Eco Mode) is now the preferred setting for maximum fuel saving, combined with the throttle settings from 1 to 10. CASE suggest that in E 10 mode a 5% reduction in fuel burn can be achieved compared to Power mode.

L (Lifting Mode) is provided for optimised lifting work, with a power boost function and a permanently activated overload warning system incorporated.

In addition, and becoming vitally important in this day and age, owners of the machine who are wanting to save money on fuel burn, will be able to limit the number of work modes available, by restricting it to Eco mode.

At floor level the track pedals and foot rests have been redesigned for improved comfort and leg room to the front has also been increased thanks to re-positioning of the seat which is now slightly set back compared to previous models.

For those fine folk who like to keep a clean cab, the new rubber mat is now in two sections, with the section immediately in front of the seat, being able to slide out easily for the daily brush out.

Talking of getting in and out of the cab, CASE have designed the left-hand joystick console to raise up out of the way, which automatically disengages the hydraulic circuit to prevent any accidental movements taking place while accessing and egressing the cab.

I put the machine to work on a pile of stone, nothing very challenging really and sadly the machine only had a 900mm digging bucket with it, a big bulker and a grader would have been nice to try out, but we had to go with what we had on the day. The machine was also fitted with the very latest Miller GTX hydraulic quick coupler.

From 13-tonne up, I’ve always enjoyed the time I have spent on CASE machines, they just feel right in every aspect, and this model was no different, easy to use, comfortable to operate and just very capable all-round.

I’ve always been one to automatically opt for the full power mode on machines in the past, as previously it always felt machines were lacking performance in eco, but as advised by Hayden Bale of CASE, I did select eco on this machine, at its maximum 10 setting.

I have to say, the machine performed very well and it didn’t even feel that I was working in a lower setting, the engineering team in Japan at Sumitomo working in conjunction with CNH have done a mighty fine job with this machine, which just purred away effortlessly as it went about its business. The combination of blue-chip Japanese hydraulic components and the European built power pack, looks set to be a perfect marriage.

The cab has lots of little improvements inside and is just a very nice place to spend your days. From the operators I have spoken to so far, they all stated that they feel CASE have really raised the bar with this series, from my experience on this 25-tonner I can really relate to those comments.

Checkout our video from the day, which features a walkaround with Hayden Bale.