by Kyle Molyneux | Tue 08 Jun 2021

Kobelco’s next-gen SK210(N)LC-11 excavator

Kobelco Construction Machinery Europe B.V. (KCME) has added all-new SK210LC-11 and SK210NLC-11 (narrow undercarriage variant) models to its range of machinery. The next generation SK210(N)LC-11 is said to deliver superior performance, greater efficiency and productivity and follows Kobelco’s elegant Performance X Design concept for excellent operator-based operability and comfort in its class.

Since the development of Kobelco’s first generation ‘SK’ 20-tonne excavator in 1983, mid-heavy machines have grown in popularity due to their versatility and suitability to all general construction applications. Equipped with the Stage 5 Hino engine, the new SK210(N)LC-11 delivers 124kW output, 143kN digging force (157kN with Power Boost) and 228kN Drawbar Pulling Force. Smooth and steady operation while moving heavy objects across the jobsite is assured through the ‘Independent Travel’ function, which dedicates one hydraulic pump to travel and one to the attachment on a continuous basis.

The machine’s higher operating weight (21,900-23,500kg) leads to increased stability and superior lifting capacity vs the previous model. When fitted with the standard counterweight (4,300kg), Kobelco says the SK210LC-11 is ideally suited for general construction and economic transportation (a requirement in some areas), while the optional heavy counterweight (4,900kg) can be fitted for heavy-duty performance such as handling heavy or complex attachments, like tilt-rotators.

The SK210(N)LC-11 has three work modes: Eco, S and H mode for optimum balance between high performance and economy and low fuel consumption (the average fuel consumption of the SK210LC-10 in Europe is currently 10.1litres/hour).

Often used on harsh jobsites, the new SK210(N)LC-11 benefits from improved durability – major components have been reviewed and improvements have been made to ensure stable performance. For example, the machine’s right and left side panels and rear supports have been made thicker to enhance body rigidity, while the increased diameter of the bucket cylinder rod pin contributes to enhanced durability for various attachments.

As part of Kobelco’s Performance X Design concept, also seen on the SK75/85MSR-7 and newly launched SK500/530LC-11 models, the SK210(N)LC-11’s cabin, ergonomics and safety features are enhanced. The Kobelco-branded Grammer air suspended seat, which moves together with the armrests and hydraulic controls for reduction of operator fatigue, provides excellent shock absorption and good ride comfort. The operator can move the levers horizontally without twisting their wrist, while the newly upgraded hydraulic control system responds to shorter lever strokes to deliver a swifter, more precise movement and improved lever operability.

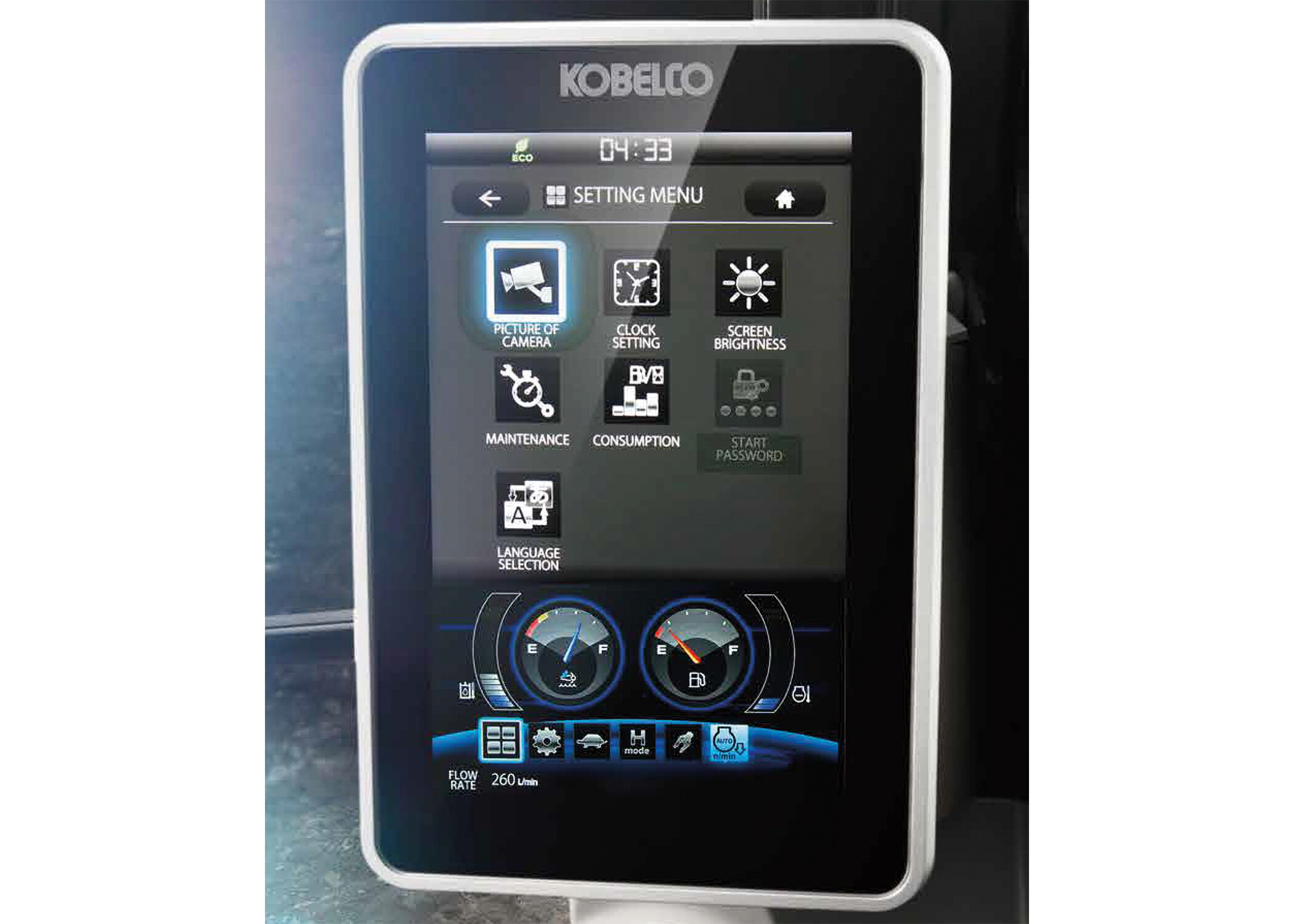

The jog dial controls multiple functions on the large 10-inch colour monitor – the menu screen facilitates reading of important information, including work mode, maintenance intervals and fuel consumption, as well as providing a birds-eye and eagle-eye view from the machine’s cameras (installed at the right and rear of the machine). While the flow-rate modes of the bucket, breaker, nibbler, and rotating grapple are set before delivery allowing the operator to start work on the jobsite immediately, mode settings for other attachments, such as the tilt rotator, can also be easily be added or changed via the monitor.

In addition, all internal switches and dials in the cabin have LED backlights to provide a bright, clear view in the dark, the SK210(N)LC-11 comes with air conditioning as standard and the cabin is equipped with a DAB+ radio (FM/AM, AUX, USB, Bluetooth and hands-free telephone) and a 12V power outlet. A password function can also be set for greater security.

Maintenance is carried out via the left side (radiator and cooling system elements), with components laid out for easy access to the radiator and cooling system. There is also easier access to the urea tank and two-stage air filter. A newly structured hydraulic oil filter prevents foreign matter from entering the oil tank during maintenance, and all fluids and filters are easy to access from ground level. The standard FOPS guard can be tilted open for easy window cleaning.

Monitoring the SK210(N)LC-11’s work status remotely has also never been easier with KOMEXS (Kobelco Monitoring Excavator System). Using satellite communication and internet, data on the machine’s operation, such as operating hours, location, fuel consumption, and maintenance status can be obtained remotely – ideal for operators of large fleets and multiple locations.

Got a news story? Email news@earthmoversmagazine.co.uk.