by Nick Drew | Wed 27 Aug 2025

Landfill with X-Appeal

Interestingly enough, Lawrence and Ernest had not come from an earthmoving or landfill business background and at the time they had both been working as hairdressers on RAF Brize Norton cutting the American servicemen’s hair on the base. Eventually the American’s left and the British took over and started some significant development work on the property.

A short while later the local water board were digging across Ernest Crapper’s field and they discovered that under the topsoil the ground was all very good quality limestone. As such Ernest and Lawrence decided to purchase a JCB backhoe loader, and a small tipper, and began extracting lime stone, which they sold into RAF Brize Norton for the building work, this soon escalated into them undertaking civils work for a local hotel development, and eventually on the massive John Radcliffe hospital development just outside Swindon.

With hairdressing now a distant memory, earthworks became a big part of what they were doing and as such they purchased an International 250 track shovel, however a larger machine was to follow as they purchased a Caterpillar 977, which Richard said nearly made them bankrupt! They also ran a fleet of Ford D-Series tippers with scow-end dump bodies, and Richard recalls the last time he saw those working was in 1974 when they were engaged on building the test track for the now long-gone Honda car factory, once a famous landmark and a major employer in the Swindon area.

The groundworks game eventually led to them getting involved in the waste and landfill industry, working on sites in Swindon, people would often ask if they did skip hire, but at the time they were not doing skips, but had the landfill operation for inert material, which eventually as rules were changing, led to them going down the waste skip hire route and saw them become the biggest supplier locally around the Swindon area.

Eventually some big national players including RMC bought them out, until later on when it fell under the Biffa waste umbrella. Sometime later they decided they that they couldn’t see any future in landfill operations, and so the Crapper family kept hold of it and in 2001 Lawrence retired. Now under Richard’s leadership the business continues to grow, and now includes compost processing and waste recycling before anything goes to landfill, it’s an impressive operation as we were about to find out.

Today the Crapper & Sons employs around 90 employees, and in addition they have a farm nearby covering some 1500 acres, with a herd of Aberdeen Angus cows, and as if that isn’t enough, they have also established a farm shop and cafe called Sustain, which offers superb produce with much of it sourced from their own farm.

The landfill and recycling operation covers some 180 acres of which 88 acres is dedicated to the landfill works with around 30 acres dedicated to the recycling plant. The facility handles in the region of 120,000 tonnes of waste per year, all of which is separated, in terms of wood they do around 35 to 40,000 tonnes per year, which is then moved on for processing into panel board or it goes for biomass.

On the compost front they produce around 25 to 30,000 tonnes per year, which is sold to local farmers, and they even have their own brand ‘Mr Crappers Potting Shed’ offering materials for keen gardeners and the like.

Richard was keen to tell us about their green credentials, “So we have also got our new initiative, which is called Sustain and will see us putting greenhouses on top of the landfill site. We have an engine running on the landfill site making electricity and that does heat as well. We’re producing around 1.2 megawatts of electricity into the system, we use half of that on site to run our plant, which includes electric powered shredders and screening units, which we have invested in since the introduction of the red diesel ban.

We have put in an 11,000 circuit, so we can power all our different elements, and with the greenhouses we aim to be able to grow all the fruit and veg for our shop, we can save money because we are not importing, and we feel we can make our produce prices cheaper than supermarkets, and we have a crazy vision of delivering our produce on electric vehicles, powered by our own electric eventually it’s all very innovative!”

.

.

Crapper’s work closely with another well-known local business MJ Church, and that good and long-lasting partnership was duly noted during our tour around the facility where we saw articulated haulers and dozers working on hire from MJ Church.

The latest piece of equipment to join the Crapper fleet is the 40-tonne class JCB 370XLC which has replaced an outgoing Hitachi Zaxis 350LC, asked what prompted the move to JCB Richard said, “We had previously purchased a JCB 220X which is just over a year old now, and we had been very happy with that, so we had no hesitation in opting for the new larger model.

Its early days but it’s been performing really well so far, and is proving to be very good on fuel burn, it has had a couple of teething issues, but they all get that when they are new, Holt JCB are very good, we have a great relationship with them, and they are always out in record time to get everything sorted, which is what you need really, I must give a mention to Ben who is one of their fitters based at the new Swindon depot, he’s brilliant and really knows his stuff with the JCB’s”.

They also run four JCB 437 wheeled loading shovels on the waste handling side, all fitted with ULRICH high-tip buckets, whilst on the farming side they run a TM320S telescopic loader, and a FASTRAC 4220 iCON both being supplied by JCB agriculture local dealer RECO.

“We have previously been running Caterpillar loaders and Liebherr in the past, but this is our second batch of JCB shovels and they are performing very well for us, so we see no reason to change going forward”, said Richard.

While JCB are dominating the fleet, there are other brands present, including two Fuchs material handlers and a Liebherr LH24 material handler, breaking news on the day of our visit was that they have a new electric powered Liebherr material handler arriving shortly, which maybe a focus for another Earthmovers site visit in the future.

On the waste compaction side, they are running the rather unusual American built Aljon 600E compactors. These ageing machines tip the scales at around 60-tonnes, and are generally powered by a 600hp John Deere diesel engine, one example was running but the other one is waiting on a replacement engine to be fitted. It was interesting to see these beasts as they are quite rare in the UK.

We headed up to the landfill operation which is surrounded by the glorious Wiltshire countryside to see the new JCB 370XLC in action.

Operator Chris Quinell (63) has been operating machines all his life and waxed lyrical about his days operating a big Demag H185 on a quarry job in Wales, which is something I always love to hear about, so it’s safe to say, he’s been around on the machine operating circuit for some time!

He has had the new mount now for about two months at the time of our visit, and has put 250 hours on the meter in that time, asked for his thoughts on the 370XLC Chris said, “For the size of the machine, it’s very fast, in every aspect and has great power, I think the new Kawasaki pumps are making a big difference to the performance.

I was a bit sceptical when Richard first mentioned getting the 220XLC model which I had first, but I have to say that was a good machine too, and its completely changed my perception of JCB hydraulic excavators. The reach on this 370 is unbelievable and its really well balanced with it too, no matter where you are working in the digging arc, even on over the side loading she stays planted, I really can’t fault it to be honest!”.

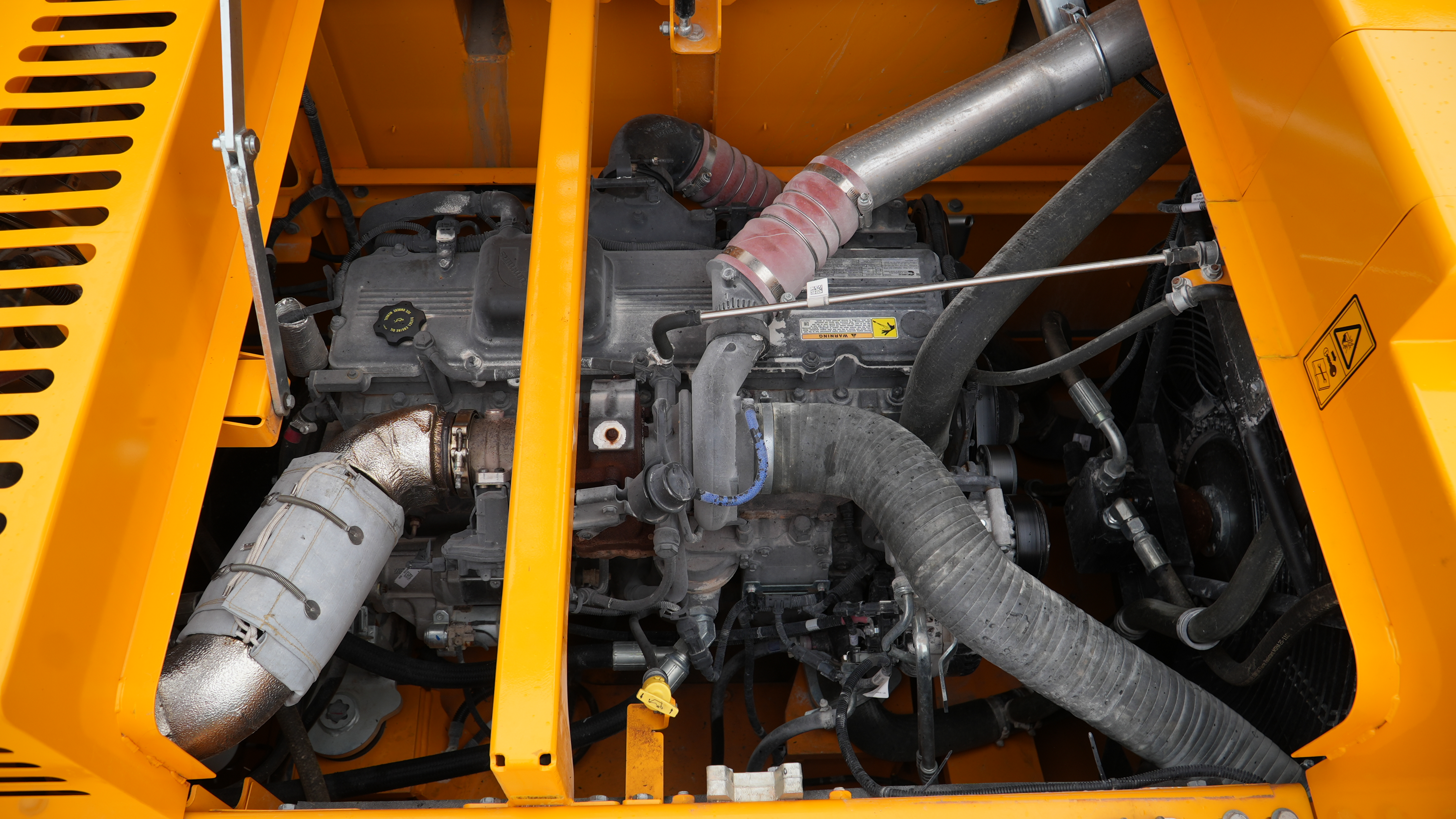

The 370XLC is powered by the latest EU Stage V and EPA Tier 4 Final emissions compliant Cummins L9 diesel engine, a well proven power pack in the heavy equipment sector.

The 8.9-litre, six-cylinder, engine is said to boast a 14% power increase over the old model it replaced and that power is always noted by operators running these new models that we talk too like Chris.

The engine delivers this maximum power within a reduced operating rev range, to increase fuel economy and reduce overall noise levels.

As previously mentioned by the operator under the skin the machine is brimming with top-quality Blue-Chip Japanese components, including the very latest generation Kawasaki tandem hydraulic pump and Kayaba (KYB) valve block. Hydraulic pump pressure has also been increased to 350 bar, but this rises to an impressive 380 bar when deploying the power boost function.

Increased diameter hydraulic service pipework, and the raised hydraulic pressures ultimately result in more power at the business end of the machine, combining to make a more powerful and smooth digging experience, this was nicely demonstrated as Chris went about his business with impressive speed, effortlessly loading heavy clay that had previously been tipped on a waste cell.

It was an impressive day out on-site learning more about this operation and the machines they use to tackle the job, it was also interesting to learn about the things the Crapper family does for the local community, which includes open days where visitors are welcomed into the facility and are given a tour around in a converted Carmichael fire engine to gain some insight into what goes on there.