by Nick Drew | Tue 07 Oct 2025

80 Years of Innovation – JCB Set to Mark Massive Milestone

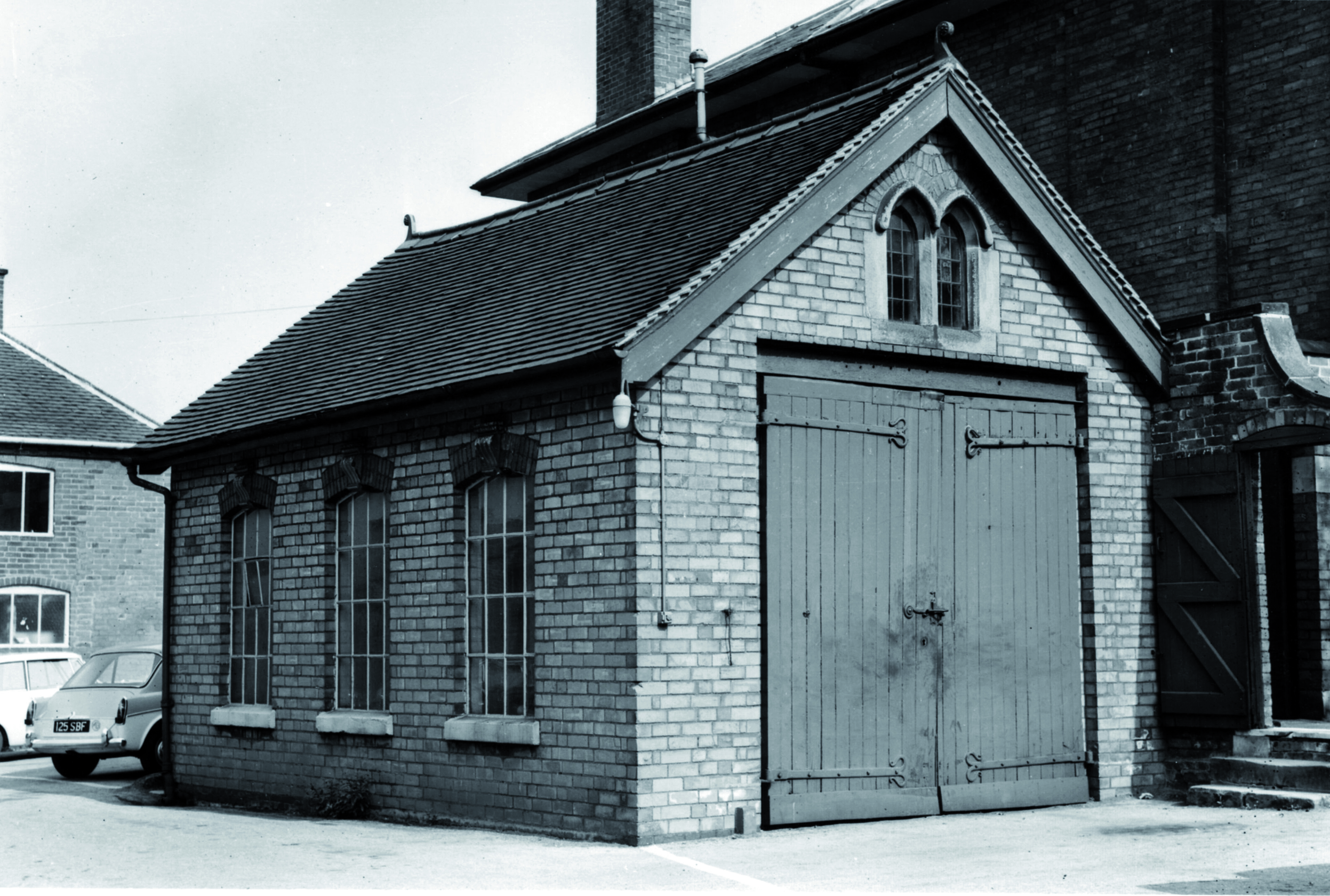

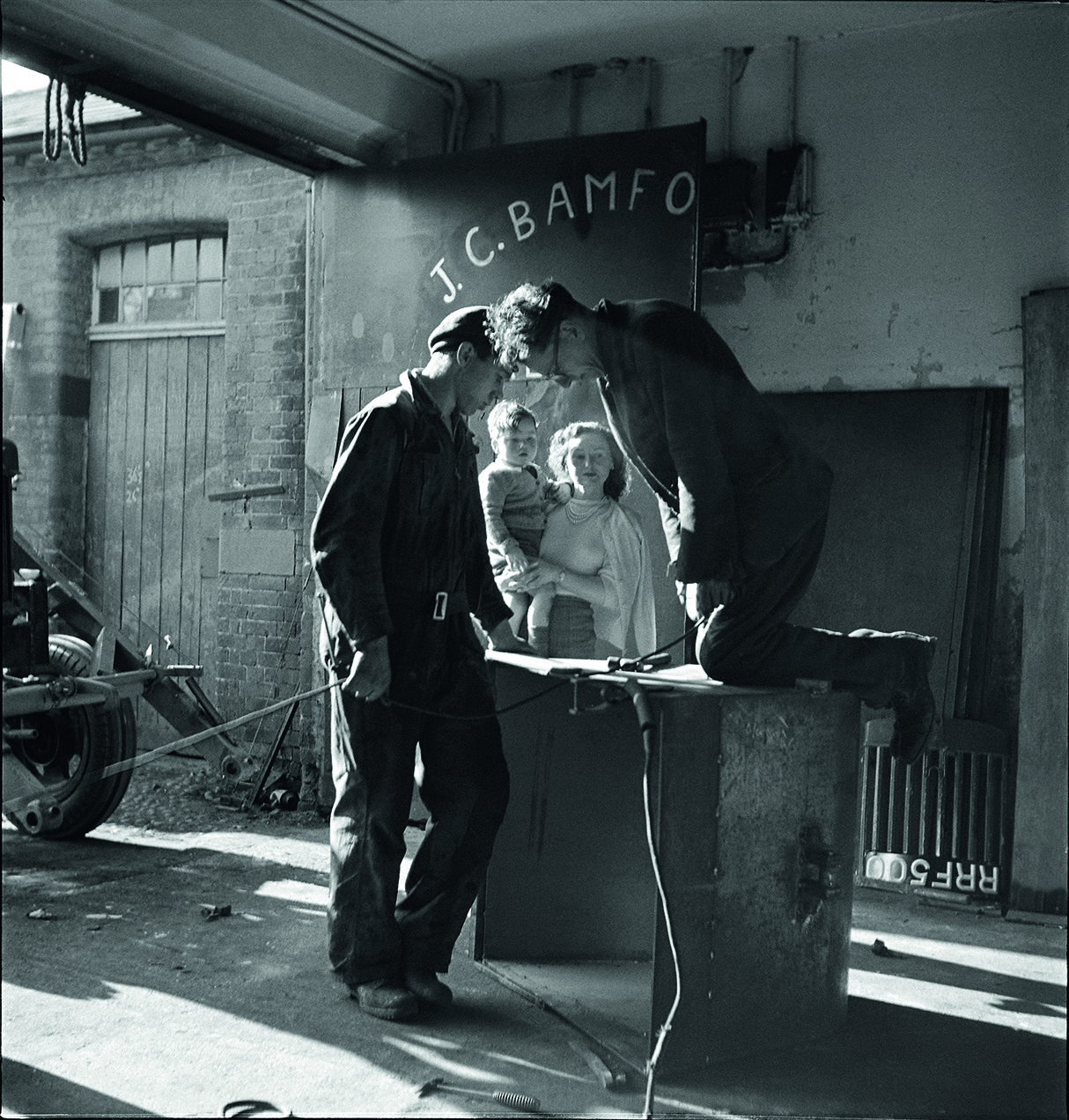

JCB was founded on October 23rd, 1945 by the late Joseph Cyril Bamford CBE in a tiny lock-up garage in the Staffordshire market town of Uttoxeter.

In this photograph heavy post, we take a look back through the archives at some of the milestone moments of the past 80 years since JCB's foundation.

It was the same day as his son Anthony, now Lord Bamford, was born and as Mr Bamford remarked “being presented with a son tended to concentrate the mind and when you were starting at the bottom, there was only one way to go and that was up.”

The foundation for the growth that was to follow was the manufacture of a tipping trailer made out of war time scrap which today stands proudly in the showroom of JCB’s World HQ.

It was produced in his garage and sold for £45 at the town’s market. The buyer’s old cart was also taken in part exchange and Mr Bamford refurbished it and sold for another £45 – achieving the original asking price of the trailer.

By 1947 the company was expanding and because Mr Bamford’s landlady also disapproved of his Sunday working, he moved a few miles down the road to a stable block at Crakemarsh Hall and by 1950 JCB was on the move again, this time to the site of a former cheese factory in Rocester, where its World Headquarters is based today.

1953 proved to be a pivotal year for new products when Mr Bamford invented the backhoe loader with the launch of the JCB Mk 1 excavator. It was the first time a single machine had been produced with a hydraulic rear excavator and front mounted shovel. This ingenuity still bears fruit today: JCB has manufactured more than 1,000,000 backhoes and they are now made on three continents.

1953 was also the year that the famous JCB logo - recognised the world over - was first used on a machine and it was eventually registered as a trademark five years later.

With the launch of a range of new backhoes, by the time the 1960s arrived it was clear this machine was revolutionising the building industry, increasing productivity and reducing reliance on manpower.

As the new decade dawned, the company was also harnessing new tools to generate business and promote the brand.

In 1961, JCB Aviation was formed and the company’s first ever plane, a twin-engine de Havilland Dove made its inaugural flight, with customers from Europe now able to make a return visit to the factory in a single day. JCB Aviation is older than many of today’s airlines.

It was in 1962 that the JCB Dancing Diggers first took a bow and JCB’s first ever overseas subsidiary in Holland was opened. A year later the JCB 3C backhoe, an acknowledged design classic, was launched. Such was the growing success of the company that in 1964, with sales up by 60% to £8 million, employees shared in a £250,000 bonus. The news made national headlines and payouts were on such a scale that some employees were able to buy their first homes with the bonus they received.

Mr Bamford declared: “I am giving you this money because I want you to share in the success of the company you have helped make.” In the same year, JCB exported its first ever machine to the USA – a JCB 4C backhoe loader.

In 1969 JCB produced a record 4,500 machines and by now was exporting more than half of them. It was in recognition of this export success, that the company received in this year its first ever Queen’s Award – the first of 27 such accolades. It was a year for awards as Mr Bamford became a Commander of the British Empire (CBE) in honour of the company’s export achievements.

As 1970 dawned JCB opened up for business in the USA, setting up a base in Whitemarsh, Baltimore to harness the huge growth opportunity North America offered.

Between 1971 and 1973 turnover doubled to £40 million. In 1975 JCB’s Founder retired, telling staff in a farewell message: “Anthony faces the tough job of moving JCB forward through the next decades into a new century. This is a demanding task but he has been well trained for it and is supported by a very strong team from works staff to management. There cannot be any limit to the successes.”

And so a new era had dawned – and one that would see huge expansion of both manufacturing facilities and product ranges.

It started in 1972 with the opening of JCB France. In 1977 the wraps came off the Loadall telescopic handler, a machine which revolutionised the way loads were handled on both construction sites and on farms. The Loadall has gone on to be one of the most successful products in JCB’s history.

1977 also marked the start of a number of high profile visits to JCB by members of the British Royal Family when HRH The Prince of Wales toured the Rocester factory.

A year later another landmark was achieved: the construction of JCB’s second factory in the UK, JCB Transmissions in Wrexham.

But it was the decision to start manufacturing in India in 1979 that heralded a period of global expansion as Anthony Bamford spotted the potential of this market. Today JCB has factories in New Delhi, Pune, Jaipur and Vadodara and India is now JCB’s biggest market behind the UK. JCB India produced its 500,000th machine in 2023.

Product innovation continued to be the lifeblood of the company and in 1985 the 3CX Sitemaster backhoe loader was launched and went on to be JCB’s biggest-ever selling backhoe. It’s also the year JCB celebrated the production of its 100,000th backhoe.

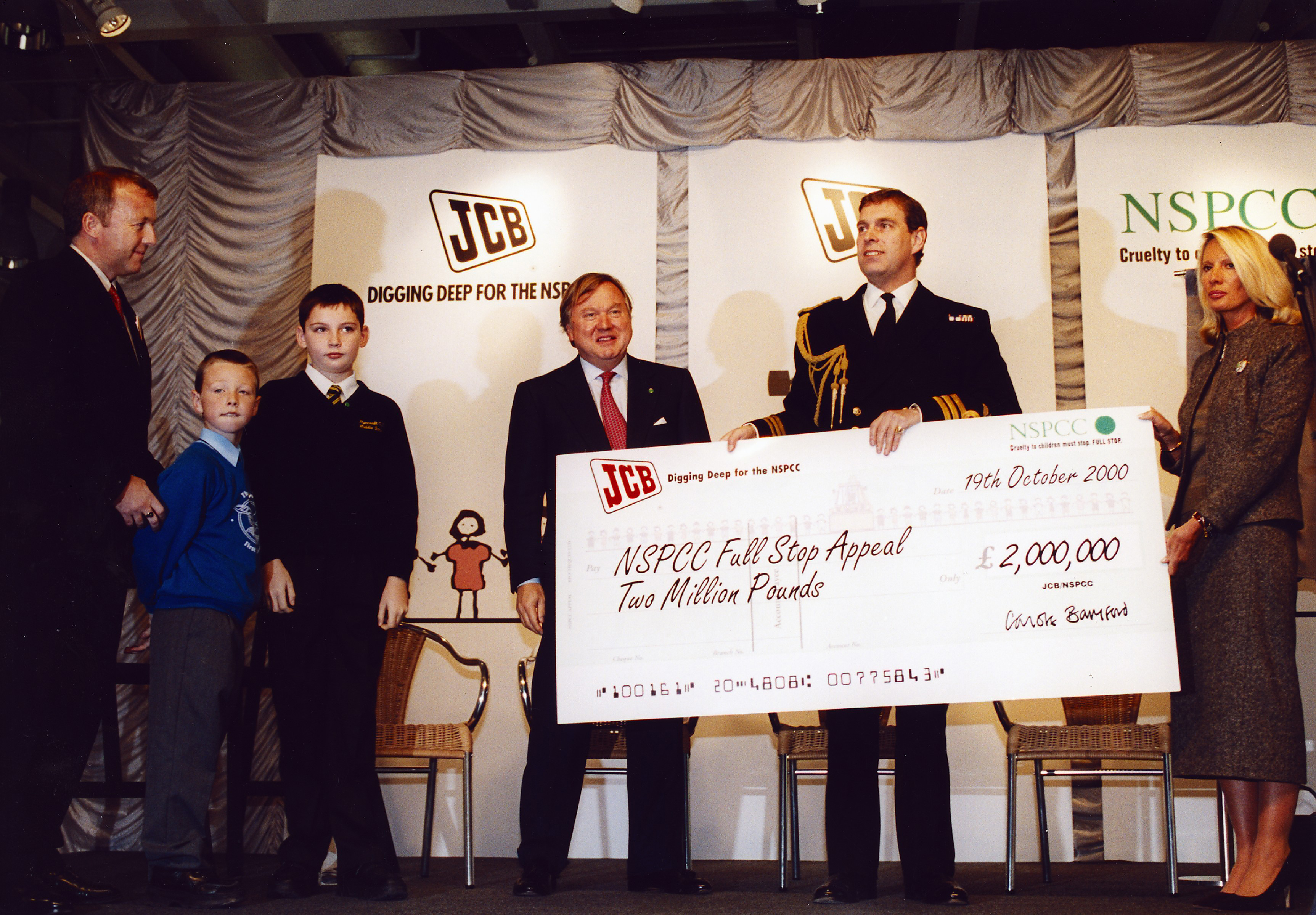

1986 was a milestone year for JCB’s charitable work when the children’s charity the NSPCC became the company’s nominated charity. It was then that Carole Bamford OBE, now Lady Bamford, instigated the setting up of an NSPCC fund raising committee when her three children were young. JCB and its employees have raised many millions of pounds for the NSPCC.

In 1987 Britain’s first female Prime Minister Margaret Thatcher visited JCB’s World HQ and drove a machine off the production line. Ecstatic crowds greeted her and one member of the public planted a kiss on the cheek of the woman dubbed ‘The Iron Lady’ as she toured the facility.

In 1988 the wraps came off the JCB GT, a backhoe capable of 100mph and a fantastic promotional tool which continues to draw the crowds wherever it appears around the world.

By 1990 JCB was expanding into new fields with the launch of the JCB Fastrac tractor – the world’s first genuine high-speed, full suspension tractor. It cost £12 million to develop and took the world of agriculture by storm. It was also the year that Anthony Bamford was knighted by HM The Queen and became Sir Anthony Bamford, an honour he said “recognised the efforts of the whole JCB team.” To celebrate, JCB employees were given an extra day’s holiday.

Product development continued unabated with the launch of the 2CX backhoe loader in 1990 followed three years later by the even smaller 1CX.

In 1994 Joseph Cyril Bamford had a rose named in his honour. Called ‘Mr JCB’, the yellow rose was unveiled in the presence of HM The Queen at the Chelsea Flower Show.

A year later and JCB was celebrating its 50th anniversary with a visit by HM The Queen to its World HQ, where she unveiled a replica of the Uttoxeter garage where Mr Bamford began his business all those years ago.

Future Labour Prime Minister Tony Blair visited in 1996 and helped assemble a 4CX and in 1997 the innovative Teletruk forklift – which can lift and place loads over obstacles – was launched. In 1998 JCB opened its second factory in Wrexham, Wales, and a year later opened JCB Earthmovers in Cheadle, Staffordshire. In 2000 the first machines began rolling off the production line at JCB’s new North American headquarters in Savannah, Georgia.

On March 1st 2001, flags at JCB factories around the world flew at half-mast following news of the death of the company’s Founder Joseph Cyril Bamford. Britain’s Financial Times newspaper said he was blessed with a rare combination of “engineering genius and marketing flair.”

In 2001 JCB expanded its charitable work with the setting up of the Lady Bamford Charitable Trust in India with the adoption of a school a few hundred yards from JCB’s factory in Ballabgarh, near New Delhi.

In 2004 employees gathered at the World HQ for a commemorative photo to mark the production of the 500,000th machine. It had taken just short of 60 years to reach that milestone. The next half million machines would be produced in the next nine years. It was also the year that JCB took the bold step into engine production with the launch of the Dieselmax engine, manufactured at JCB Power Systems in Derbyshire.

In 2005 JCB opened its factory in Pudong, China and announced news of the biggest ever order in its history, a $140 million deal to supply the US Army with a high-speed backhoe loader for military engineering tasks, a machine known as the High Mobility Engineer Excavator (HMEE).

This year also saw JCB set a world record with the JCB Dieselmax streamliner car. Powered by two JCB Dieselmax engines, it reached speeds of 350.092mph on the Bonneville Salt Flats in the USA to attain the record of the world’s fastest diesel car, a title it still holds today. Sir Anthony Bamford joined the team on the Salt Flats to celebrate the successful outcome of his idea.

JCB’s support of underprivileged children spread further around the globe with the opening in 2007 of the Lady Bamford Center for Early Childhood Development in Savannah, Georgia to support the education and social development of pre-school children. It was in this year that JCB achieved its highest ever machine sales of 72,000 units.

Meanwhile, in 2008 JCB Heavy Products – which manufactures tracked and wheeled excavators - moved to its brand new factory on the outskirts of Uttoxeter. This was followed in 2009 by a £40 million investment in JCB’s factory in Ballabgarh, India to create the world’s biggest backhoe loader factory.

In 2009 HRH Prince William followed in his father’s footsteps of 32 years earlier when he toured the company’s headquarters and helped employees celebrate the production of the 750,000th machine.

A national shortage of engineers inspired Lord Bamford to establish the JCB Academy in Rocester, Staffordshire in 2010 to train the country’s engineers and business leaders of the future. The facility has been a resounding success with around 3,500 students passing through its doors and with every single one going on to employment or further education. JCB also announced a $40 million project to develop a brand new range of skid steer and track loaders to be manufactured at its North American HQ.

As it looked to the future, JCB also celebrated its heritage with the opening of the ‘Story of JCB’ in 2011, a permanent exhibition marking the growth of JCB and the Bamford family’s roots in industry. These roots can be traced back almost 200 years when they started out as blacksmiths in Uttoxeter, before, in 1871, they founded agricultural machinery suppliers Bamfords Ltd in the town.

Global manufacturing extended to Brazil in 2012 and British Prime Minister David Cameron officially opened the new £63 million facility in Sao Paulo state. This year JCB also celebrated securing a £60 million order for more than 1,000 backhoes from the Brazilian Government.

As JCB approached its 68th birthday in 2013, a new independent economic report revealed the company supported 24,000 jobs in the UK and contributed £545 million to the British Exchequer. Hundreds of employees also gathered outside the world HQ for a commemorative photograph marking the production of the one millionth JCB machine. It was also a momentous year for JCB’s Chairman Sir Anthony Bamford as he became Lord Bamford.

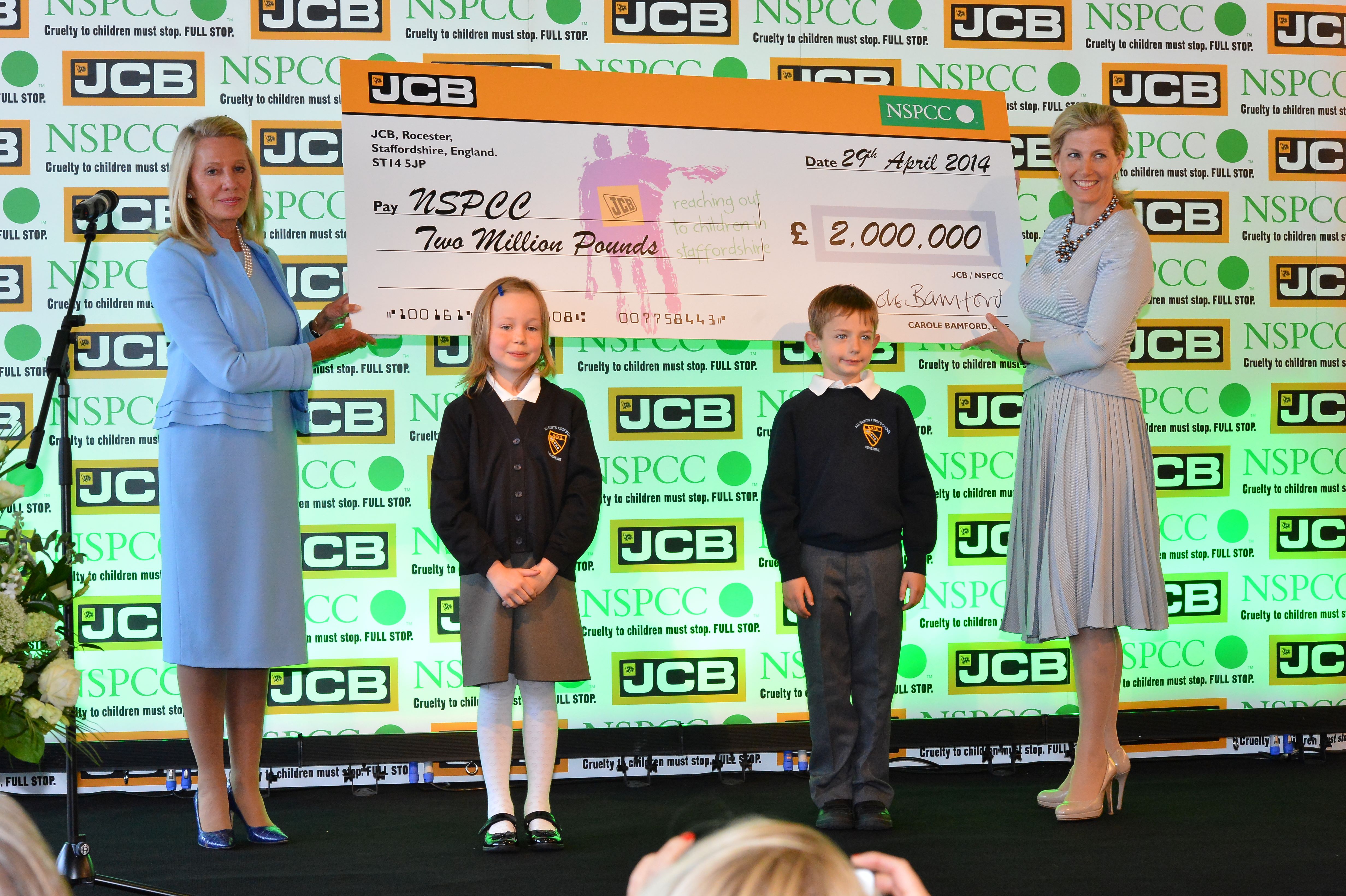

In 2014, Lady Bamford presented a cheque for £2 million to HRH The Countess of Wessex for the NSPCC after a marathon company-wide funding raising drive. Employees raised £1 million and the amount was doubled by Lord Bamford. In India, production started at JCB’s new £62 million Jaipur factory complex and plans were announced for a £20 million new HQ for JCB Germany in Cologne.

In 2015 JCB marked its 70th anniversary with a continued focus on product innovation as the wraps came off the brand new 3CX Compact backhoe loader, a machine 35 per cent smaller than its bigger brother and designed to work on increasingly congested building sites.

2016 was a year of milestones as the company celebrated the production of the 200,000th Loadall telescopic handler. It took almost 30 years for JCB to sell the first 100,000 Loadalls but it has taken less than 10 for the next 100,000 to be sold – testament to the growing importance of the product and JCB’s strength in this sector. Today JCB is the world’s number one producer of telescopic handlers. In this year JCB also marked the production on its 100,000th mini excavator and celebrated 25 years of production of the revolutionary Fastrac tractor. It was also the year when the new JCB Hydradig was launched to international acclaim.

2017 was also a momentous year on two fronts: the launch a new range of JCB powered access equipment after two years of secret development. JCB was entering for the first time a market worth $8 billion a year. The year also saw the company celebrate another Loadall milestone – 40 years since production started. Later in the year JCB marked the production of its 500,000th engine - enough engines to stretch from London to Paris.

If 2017 was a year of milestones, 2018 was certainly a year for exciting product introductions with the unveiling of JCB’s first ever electric excavator leading the way. The 19C-1E electric mini excavator was developed in response to customer demands for a zero emissions machine which could work indoors, underground and close to people in urban areas. Once fully charged, it is ready to put in a full normal working day on the building site. The year also saw the launch of the hugely successful X-Series range of tracked excavators and the start of site dumper manufacturing at the World HQ in Rocester. JCB also announced a £50 million investment in a new factory to produce cabs in Uttoxeter.

By 2019 the new electric mini excavator was in full production at JCB Compact Products in Cheadle, Staffordshire, with the initial first 50 orders delivered to customers. It was also a year for records. In June of that year, JCB set a Guinness World Record for the fastest tractor at Elvington Airfield in Yorkshire. Called Fastrac One, the tractor reached a speed of 103.6 mph with motorbike racer and lorry mechanic Guy Martin in the driver’s seat. JCB then embarked on an ambitious plan to break its own record and developed Fastrac Two – which is 10% lighter and even more streamlined than its smaller brother. In October, Fastrac Two hit an astonishing peak speed of 153.771mph on its way to recording an average of 135.191mph at Elvington. In 2019 Chairman Lord Bamford officially opened a brand new £50 million headquarters for JCB Germany.

Tributes were paid to a former JCB employee who joined the company as a teaboy and rose through the ranks to become a director. Bill Hirst MBE, who was the third person recruited by JCB in 1947, passed away in January 2020 aged 86.

In 2020 a refreshed range of JCB Fastrac 4000 Series tractors was introduced with uprated axles for increased payloads and durability, along with new tyre options and a locking front axle differential for increased traction in the field.

In March 2020, JCB marked the production of the 750,000th backhoe loader before the world became a very different place as the Covid-19 pandemic took hold. When the company’s production lines fell silent in March, JCB turned its attention to helping those in need during the unprecedented times.

In India and the UK, company chefs prepared more than 200,000 meals for those most in need. A Staffordshire production line closed down as a result of the Coronavirus crisis was re-opened to produce prototypes of special housings for a new type of ventilator following a national call to action.

JCB also reopened its Innovation Centre at the World HQ in Rocester so that employees could volunteer to make medical grade visors for NHS staff on the company’s 3D rapid prototype machines.

By the time production lines re-opened in June, JCB was also previewing an exciting new development after developing the construction industry’s first ever hydrogen powered excavator as JCB continued to lead the sector on zero and low carbon technologies. The 20-tonne 220X excavator powered by a hydrogen fuel cell has been undergoing rigorous testing at JCB’s quarry proving grounds for more than 12 months. The exciting development meant JCB became the first construction equipment company in the world to unveil a working prototype of an excavator powered by hydrogen.

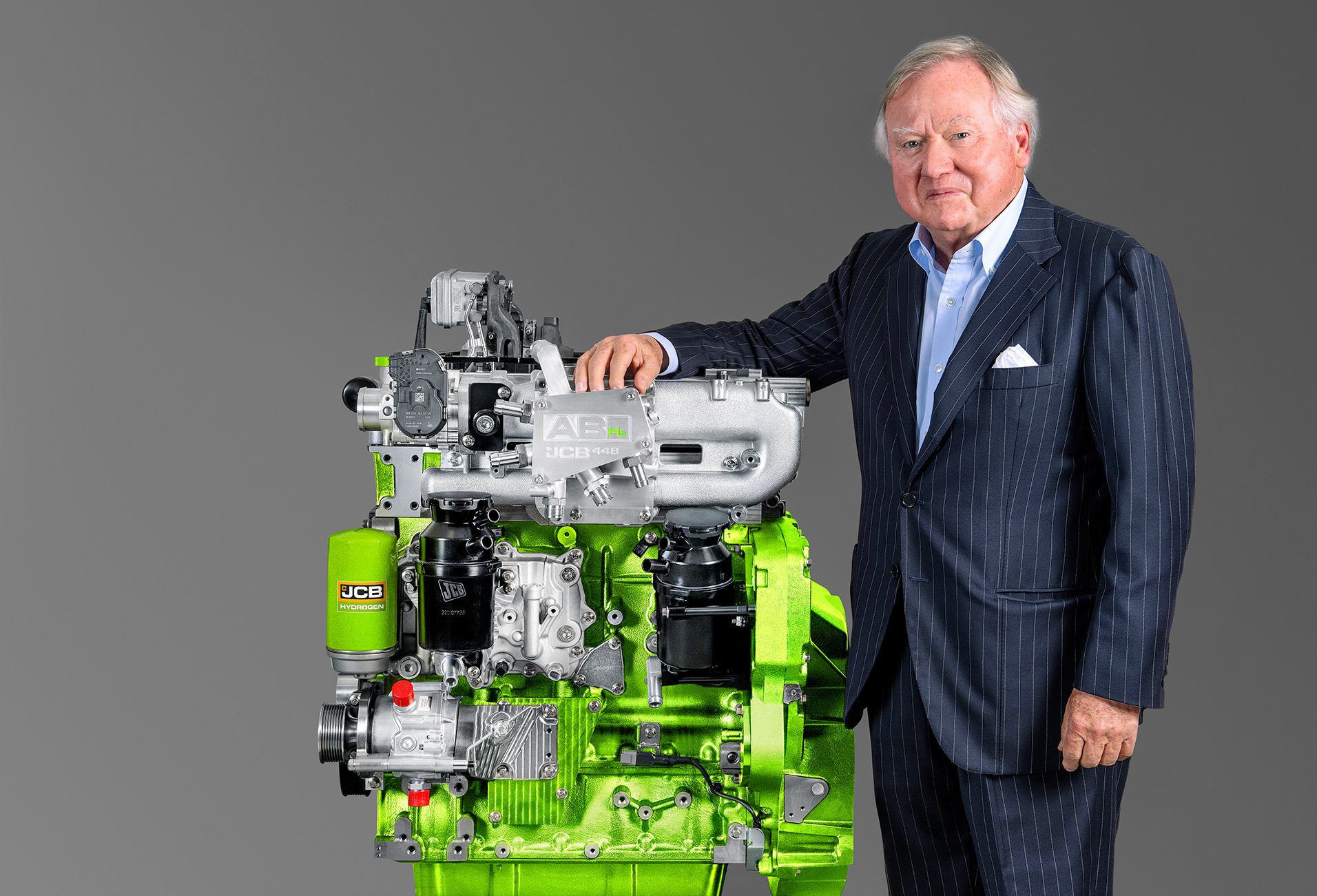

This innovation consolidated the belief that hydrogen could be the fuel of the future but JCB switched away from fuel cell technology in 2021 when JCB Chairman Anthony Bamford challenged the company’s engineers to make a major breakthrough in the use of hydrogen as a fuel in a combustion engine.

He has since personally driven the pioneering project at JCB’s engine plant in Derbyshire which has seen 150 engineers employed and investment of more than £100 million to produce a range of super-efficient hydrogen engines.

In 2021 Britain’s biggest equipment rental company invested in 2,100 new JCB machines in a deal worth £65 million – the biggest ever order from a UK customer in the company’s history. Sunbelt Rentals UK expanded and renewed its fleet as the construction industry rebounded strongly from the Covid-19 pandemic.

Also in 2021, JCB’s revolutionary Pothole Pro machine was unveiled before hitting the road for a nationwide demonstration tour. The PotholePro allows the contractor or local authority to cut the defect, crop the edges and clean the hole with one machine – mechanising jobs traditionally done by pothole gangs and delivering up to a 50% cut in daily costs.

In 2021 a talented JCB engineer who amassed a multi-million pound fortune thanks to his interest in cars bequeathed £125,000 to the JCB Academy, which is dedicated to nurturing the engineers of the future. Bill Turnbull spent almost a decade working at JCB as Chief Engineer helping to develop the company’s first ever mini excavators. He retired in 1995 at the age of 65. When he died in 2019 aged 88, he left more than £4.2 million in his will thanks to an investment he made more than 50 years earlier in a rare 1937 Bugatti Type 57S.

Meanwhile JCB employees embarked on a major fundraising drive for children’s charity the NSPCC with the launch of a £70,000 appeal. The JCB NSPCC Platinum Jubilee Appeal ran until 2022 to coincide with celebrations to mark the Queen’s historic 70-year reign.

On the sporting front, JCB’s Golf and Country Club realised its vision to be a major international tour destination as some of the biggest names in the sport descended on the course for the JCB Championship as part of the Legends Tour’s international schedule.

In 2022, JCB’s double-award winning electric mini excavator marked a significant milestone in its short history – the production of the 1,000th machine.

JCB’s newest UK factory, JCB Cab Systems, was officially opened in November 2022 by HRH The Countess of Wessex who also received a cheque for £300,000 for the NSPCC, following a successful employee fundraising campaign.

JCB, having developed the world’s first working construction machines powered by hydrogen, unveiled another world first for the industry - a mobile hydrogen refueller, providing a quick and easy way for customers to refuel their machines on site.

The world’s first digger powered by a hydrogen combustion engine was given a right royal outing in a June 2022 parade marking the Queen’s 70-year reign. The JCB backhoe loader – in distinctive green and white livery – was cheered loudly as it made its way along The Mall in London towards Buckingham Palace driven by JCB Test Site Operator Georgina Williams, 30.

As the national mourned the death of Queen Elizabeth in 2022, JCB opened books of condolence to enable employees to pay their own special tributes. The books opened at factories in Uttoxeter, Cheadle, Wrexham and Foston, Derbyshire. At JCB’s World HQ, the book of condolence in the main reception was also available for retired employees and members of the public to sign during office hours.

Later in the year, Shadow Chancellor Rachel Reeves was given a detailed insight into JCB’s £100 million investment in super-efficient hydrogen engines. The Leeds West Labour MP toured the engine plant, where she was shown the production area and detailed testing processes involved in developing the engine

2022 was rounded off in style with the successful launch of the JCB Christmas Toy Appeal with employees donating hundreds of gifts for distribution to children in the local community.

Thousands of JCB employees took part in a right Royal celebration to mark the Coronation of HM King Charles III – with a company-wide ‘street party’.

In 2023, JCB treated more than 5,500 employees at all its UK factories to a two-course celebration lunch. The ‘Big Coronation Lunch’ was staged at the company’s plants in Staffordshire, Derbyshire and Wrexham where breaks were extended to allow the historic occasion to be marked in style.

With prototypes tested across numerous applications over the next two years, JCB’s hydrogen combustion engine was shown for the first time at the 2023 CONEXPO-CON/AGG exhibition in Las Vegas in March.

In the summer of 2023, more than 320 runners embraced a party atmosphere to help celebrate four decades of a popular annual JCB road race. They lined up for the 40th anniversary JCB Lakeside 5 and Fun Run cheered on by friends and family as they took on the five-mile main course and two-mile fun route around JCB’s World HQ in Rocester. JCB Chairman Anthony Bamford cut a celebratory cake.

In the autumn of 2023 JCB announced it was set to build a new factory San Antonio, Texas - the biggest investment in its 78-year history. The investment will create 1,500 new jobs over five years. Ground was broken the following year.

In 2024, a new truck, the JCB DIGatron, hit the world stage, driven by Tristan England, and thrilling families and motorsport fans at Monster Jam events.

A unique JCB tartan tractor rolled off the production line at Staffordshire’s JCB Landpower factory honouring Scottish rugby legend and motor neuron disease (MND) campaigner Doddie Weir.

In February 2024, JCB Chairman Anthony Bamford celebrated an unprecedented milestone with the family firm – 60 years’ service.

JCB introduced DualDrive - the latest productivity enhancing innovation for its backhoe loader models. DualDrive allows the operator to drive and reposition the machine while facing the excavator, without having to turn the seat to the front-facing position.

The first LIV Golf by JCB tournament took place in the summer of 2024 at the JCB Golf & Country Club, putting the stunning 240-acre course in the international spotlight.

In the summer of 2024, applause rang out for Paris Olympics silver medallist Adam Burgess as he was given a rousing welcome home by employees at his sponsors JCB. He was greeted by employees waving flags as he arrived at the World HQ.

In October 2024, JCB marked a major manufacturing milestone with the production of its one millionth engine.

As JCB’s 80th anniversary year got under way, HM The King visited the World HQ to the delight of thousands of employees. His Majesty was given an insight into JCB’s hydrogen engine combustion technology by Anthony Bamford.

In January, the one millionth JCB backhoe rolled off the production line and was celebrated with a cavalcade of classic models from the seven decade history of the iconic machine. A unique 4CX model, decorated in graffiti art by London-based artist and illustrator Dave Smith, was presented to Lord Bamford.

In 2025 JCB secured the first full EU type-approval for its hydrogen engine for use in non-road mobile machinery. This means the engine is approved for sale and for use in machines and third-party OEM equipment in each of the 27 EU member states, and all other territories recognising EU type-approvals (e.g. EEA and EFTA territories). Then in April, the UK Government made the historic decision to change the law - allowing hydrogen fuelled construction and agricultural machinery to use the public highway. JCB has produced more than 130 evaluation engines which are powering backhoe loaders, Loadall telescopic handlers and generator sets. Real world pre-launch testing of JCB’s hydrogen equipment is now at an advanced stage and progressing well.

Lord Bamford said: “JCB’s customers are patiently waiting for our hydrogen-powered equipment to make a difference on their job sites. They won’t have much longer to wait.”

JCB Transmissions will soon produce its 3,000,000th component and the year of celebrations will culminate on October 23rd - which marks the 80th birthday of JCB Chairman Anthony Bamford and 80 years of JCB - a truly historic moment in the history of British manufacturing.

For the younger generation, checkout this video round up featuring 80 Years of JCB in 80 Seconds, which has been put together by JCB's marketing team.