by Nick Drew | Tue 24 Oct 2023

Changing Tides, Changing Times (A Tribute Post)

Last week I received the sad news of the passing of Chris Prynn who was the driving force behind Padstow Sea Sand, today I am posting my recent article as a tribute to a great man, who for me and many others, it was an honour to know.

Our last visit to Cornish family business Padstow Sea Sand was back in 2017, and we featured them in the February 2018 edition of Earthmovers Magazine, however, there has been a lot of significant changes to the way the operation is conducted and to the business itself since then, and as such I was delighted to be invited back down to meet up with Chris Prynn and his two sons Matt and Jack to see what’s new at this most famous fishing port location.

As reported last time around, the sea sand extracted here is a premium product that is in big demand thanks to its high lime content, and the softness of this pH rich material, which is often used as a cheaper alternative to straw bedding for farm animals, and which in turn afterwards can be recycled by spreading on the land to act as a natural fertiliser. In addition to this it is highly sought after as a non-abrasive, and soft under hoof material for horse riding menages.

Traditionally the boys had been using the long-established method for extraction, which consisted of a tracked excavator and a team of tractors and trailers, who at low tide would trundle out to the sand bar to dig and load the sand away, the tractors would then head to the harbour wall to tip the loads which was then grabbed by an ageing Akerman H14B and stored on the quayside prior to loading onto road going trucks. The operation serves two purposes, it raises a top-quality product to sell on, and most importantly dredges the harbour, an operation that is constantly needed due to the movements of the tide.

The first thing I noticed was that the old Akerman has long since been retired, and replaced on the harbour wall by a much larger 36-tonne Volvo EC360BLC, but its out in the harbour itself where the most significant changes have taken place.

History had previously shown that Mother Nature was constantly changing the way the river reacted and how its movement affected the operation. As the years rolled by these changes were becoming ever more drastic, and Chris and his late father Ed knew that eventually they would be forced to change the way they do things.

Chris takes up the story, “The river was changing and I was noticing that we were getting less and less production time, eventually getting down to just 45 minutes of excavation time at low tide, I thought we would just have to stop as it was becoming economically unviable, with our production costs being way above our revenue on the product. So, I called Matt and Jack in to discuss the situation and simply said to them, well boys, what do you want to do, they looked at me a bit vague, but I reiterated that we simply could not continue like this.

With my experience of working overseas in Nigeria with Volker Stevin on dredging equipment, I felt the only solution was to bring in a pontoon with an excavator mounted on it, and barges with a tug to ferry the sand back to the harbour wall. The boys looked at me as if I had gone mad, but the reality was, it was the only way we could go to keep the business afloat, quite literally! (Pun intended)”.

It was a difficult time for everyone at Padstow Sea Sand, especially during the COVID period and the team needed help, fortunately for Chris and the boys, they had good friends around who were willing and able to help out during this difficult period. These friends and industry colleagues included Land and Water Services Ltd, WH Bond & Sons Ltd, Terry Harris & Sons, and R.L Taylor Ltd, all of whom have played a massive part in helping to bring this new set up to fruition.

Chris continued, “Land and Water spent over 2.5 years putting a deal together for us, and we are indebted to Ben Clarke who was the original guy I touched base with at the firm, an absolutely smashing chap who along with Richard Maclean, we simply cannot thank enough. Ben was regular visitor to our base on the harbour, and together we worked out what equipment we were going to need”.

Chris wanted a particular type of tug boat, and one that matched his requirements was found way up country in Scotland. This particular vessel was said to be in need of some work to make it serviceable again, and when it was eventually transported down to their yard in St Eval, the reality of the amount of work needed was clear to see, there were some glum faces all around and despite the boys’ doubts, they found a ship welding repair company who put in a sterling effort to get it sea worthy again including welding in a new bow section. A new replacement marine engine was fitted, all the electrics were renewed and the hydraulics checked over. Just a couple of years later the Karenza was officially launched at Padstow with long term family friend Chris Simpson in place as the captain.

The two barges had already been brought down from Land and Water as they had needed to free up some space in their yard, all that was missing at this point was the pontoon and an excavator to put on it. The pontoon itself required a lot of work to make it suitable for the application, the support poles for example needed to be extended, and Jack who is a skilled mechanic himself, worked day and night to get it sorted.

The original plan was to mount their existing Volvo EC210CLC onto the pontoon, but they soon realized that it would quite simply not have the dig depth capacity required to do the job, Matt made one vital phone call, and at 6am next morning the low loader was leaving the yard to go and pick up the Komatsu PC210LC 15.5m long reach boom hydraulic excavator which was to be the last piece of the jigsaw mounted on the pontoon.

Sometime beforehand Matt had met a guy with a lot of dredging experience down at Falmouth Docks, called Rodney O’Neill and they had actually had a row and fell out, however in time they eventually started talking again and Rodney said to Matt, if you need any help when you get this dredging operation going, I will come over and give you a hand.

It turned out that Rodney was a man of his word, and he came over as the operation was in its infancy. Rodney turned out to be a hard taskmaster, described by the boys as a bit of a Sergeant Major, but he was determined to set the boys on the right path to success, sharing his years of dredging experience and offering great tips along the way.

Unfortunately, with the operation on the water just getting going Chris and the family were dealt a massive blow as his doctor had to tell him that he had cancer and his life expectancy was not great. Chris said “The night they started the dredging operation they did two cargo loads, I was down the hospital, having just been told the news about my illness, the boys contacted me on Facetime to show me that it was all going to plan, and I’m not ashamed to say, I cried like a baby having seen that video, because I couldn’t physically be there with my boys, who we have had to train from scratch and of whom I am immensely proud, I would now say that I’d be happy to put our local boys up against any other dredging crew out there”.

Eventually Rodney left and the lads were left to get on with it on their own, the next day determined to show their metal, the boys turned around 8 barges, the previous highest tally was 7, the next day they did 10 barges and one day later they managed 12 loads and that set the pace for the future.

Before any of this happened there were lots of issues to be sorted, in terms of legislation and those all-important health and safety courses to attend. One can imagine that this is even more complicated than for those working on construction sites, as you would need tickets to operate the machines, then in addition require all the relevant maritime qualifications too, apparently the lads have had to attend six courses to become fully compliant.

Chris explained that things are still very tight financially, especially considering that for a 5-month period they could not dredge any sand at all, a situation that hurt the business badly, but Matt recently picked up an order for 7.500-tonnes of material which will start to put them back on there feet in the post Covid world.

Pictured above: Bryn Phillips Padstow Harbour Master (Left) & Nick Billing Deputy Harbour Master (Right).

“There were people in Padstow that doubted the whole operation, suggesting it would be no good, the tide is too much, the tug boat is not big enough, so many doubters and haters, but the right people had faith in us and our abilities, the Harbour Master Bryn Phillips and his Deputy Nick Billing supported us massively, at the same time they also expressed some reservations, but now they have seen it work for themselves” commented Chris.

Talking about the machines Chris said, “We have historically been Volvo men down here, but I can tell you this, we are not afraid to buy Komatsu now after our experience with the PC210LC, it’s been a great piece of kit and very reliable, our highly experienced operator Maurice Murt, really rates it in terms of performance and reliability. We will be in the market to replace the old Volvo EC360BLC on the quayside before much longer, as she is well over 20,000 hours on the meter now, and we will without a doubt consider a Komatsu equivalent to replace her when the time comes”.

The sand screening operation continues at their facility in St Eval, with articulated lorries bringing the dredged material in for processing, while other trucks transport the material to customers. The venerable Volvo L150G wheeled loader is still the same machine we saw during our previous visit and has served them very well.

As another sideline the boys have also diversified into general plant hire with a variety of hydraulic excavators and mini excavators available for hire.

Summarizing during a rather emotional chat Chris said, “I had to prepare everything in case I go too soon, I just, had to know that the boys had everything in place to continue the business without me, I’ve tried my best to make them financially secure going forward, make no mistake, we have been to hell and back to fight for our survival and with the help of some of the best in the business we are back on our feet”.

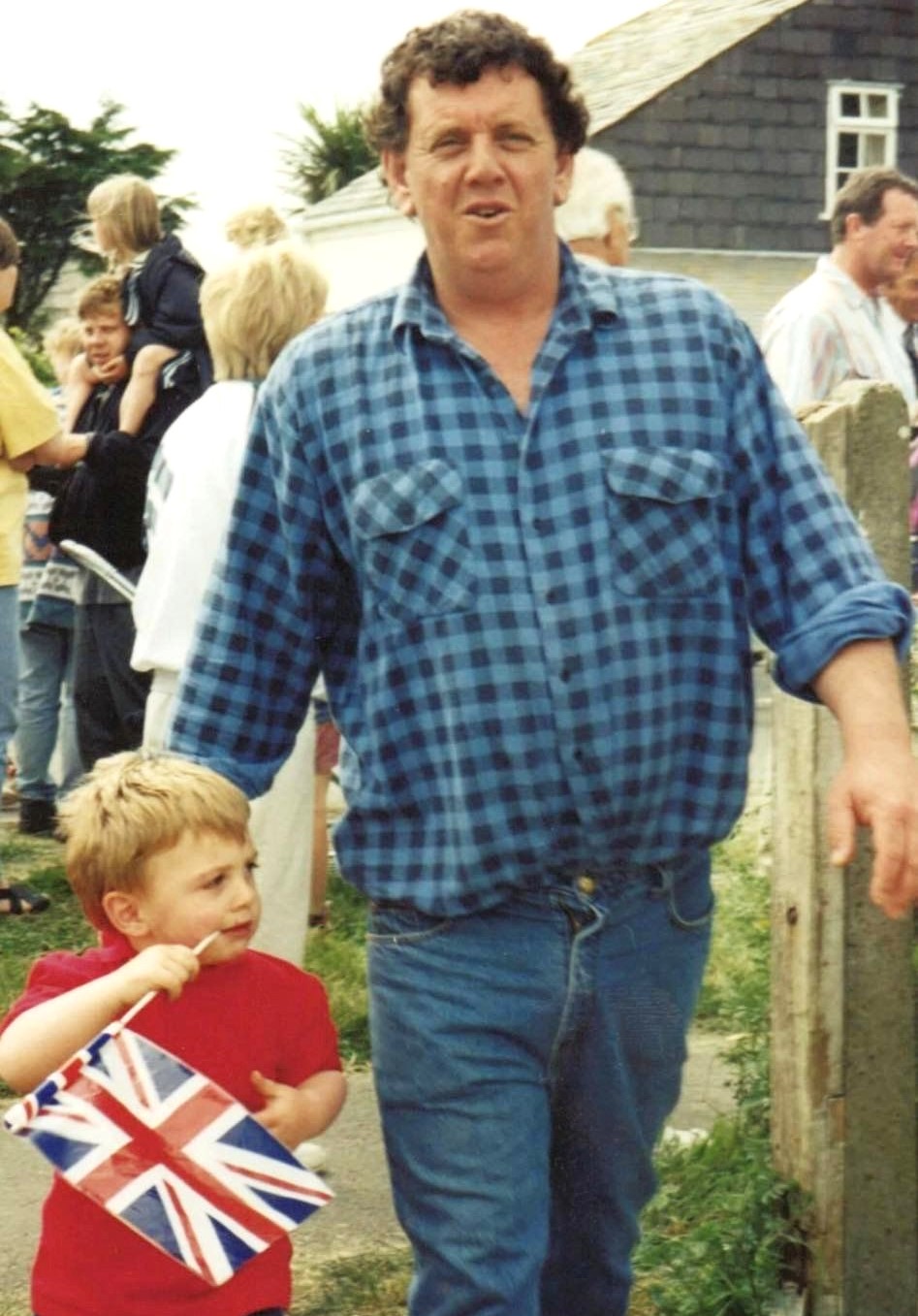

Photo: Left to Right ... Jack Prynn, Chris Prynn, Matt Prynn, Chris Simpson

DEDICATED TO THE MEMORY OF MR CHRISTOPHER JOHN PRYNN 1955-2023 RIP.