by Nick Drew | Tue 11 Aug 2020

European Focused

Taking a look back at one of my articles previously published in Earthmovers Magazine, bringing it to life on the internet with alternative photos and video footage.

Austrian based multi-facetted construction equipment manufacturer Wacker Neuson continue to develop and upgrade their mini excavator range. In November 2018 they launched two zero tailswing mini excavator models into the UK the EZ26 and EZ36.

These machines replaced the previous models namely the EZ28 and EZ38 and have been enriched with a number of new features including new cabs and panels. The machines still feature much of the well proven Wacker Neuson technology under the skin including the hydraulic system and associated components for starters and as we were about to find out, a whole host of other neat little features which have been added.

Ben Dommett of Gloucestershire based dealers Equipment One invited us along to try out the heavier EZ36 machine and to take a look at a couple of EZ26 that have already been sold to local customers.

First up was the 3.5 tonne class EZ36 on this occasion in its VDS (Vertical Digging System) configuration, a unique Wacker Neuson feature which is ideal for those occasions when you have to excavate on a slope of anything up to 27%, for example when digging on a verge for telecom services and the like, this system will enable you to dig an upright square trench by adjusting the upper carriage to suit and like all Wacker Neuson kit, its well-engineered and up for the job.

This particular example had been purchased by its new owner local contractor Philip Snow who very kindly allowed us to get hands on with it.

One thing that caught my eye straight away was a new footstep on the side to aid access into the cab, this is nothing radical, but it’s a simple idea and as is so often the case, simple ideas are often the best. As I understand it, this is a new feature on the VDS machine, as the system does mean the cab entry point is slightly higher than on the conventional models.

At the business end of the machine, the EZ36 comes direct from the factory with full metal hydraulic pipe work for the quick hitch as standard, as is the long dipper arm and auxiliary & hammer line pipework, this is also the standard specification for the 2.5 tonne class EZ26 too. This example was fitted with a Whites Totalock 2 fully automatic hydraulic quick hitch and buckets.

The dipper and boom rams are fitted with check valves as standard and the boom ram also features a metal ram guard to prevent damage from accidental contact of the chrome rod by a bucket tooth or any other arm mounted attachment.

According to Wacker Neuson the machine features one of the largest off-sets in its class, offering 70o to the left and 45o to the right. Maximum dig depth with the long arm is 3,422mm with a maximum reach at ground level being 5,629mm.

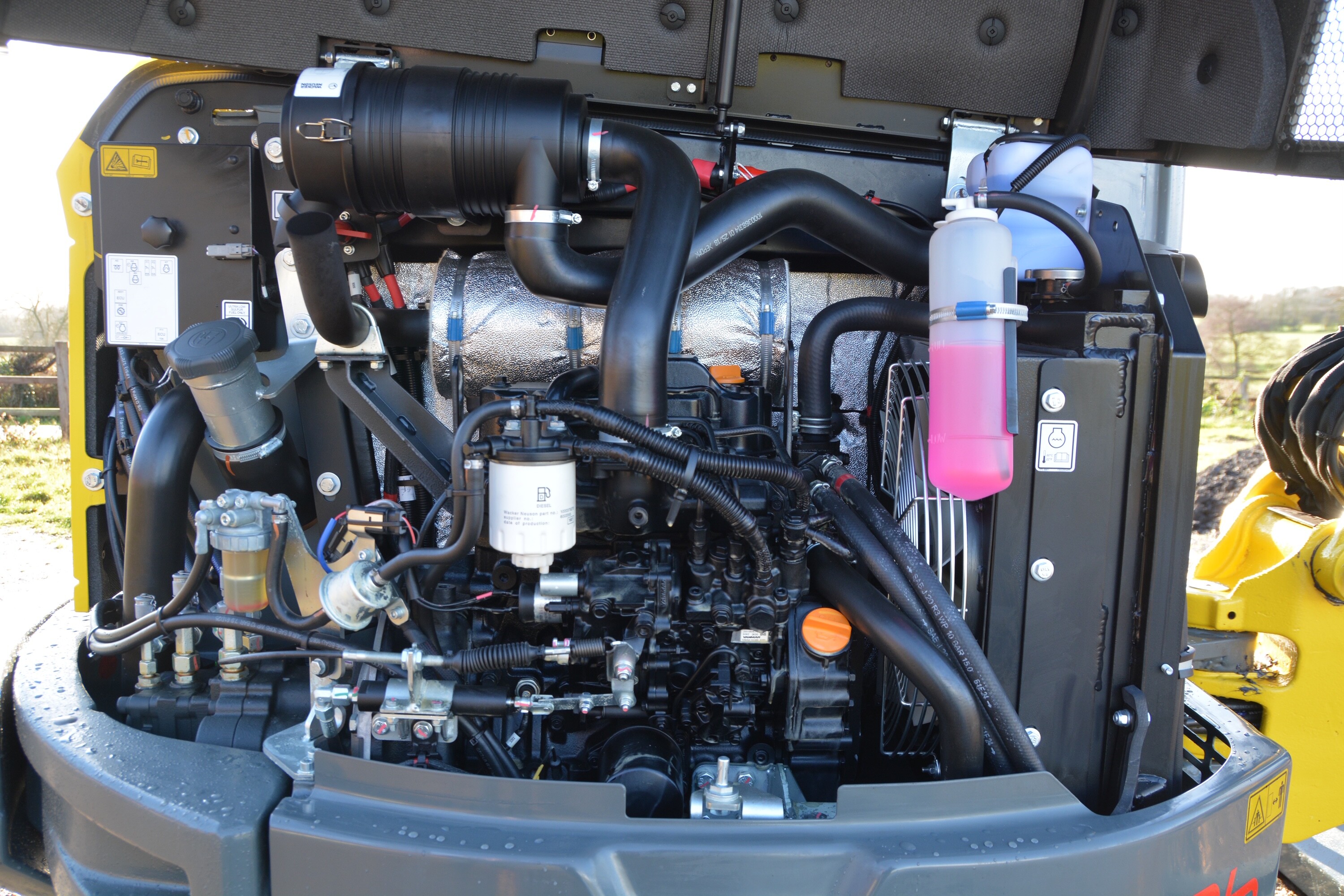

These machines feature a side mounted engine which is accessed by popping up the full-length engine hood. Once in the raised position it allows great access to the engine which in this case is the well proven 3-cylinder Stage 3B/Tier4 emissions compliant Yanmar 3TNV88-EPWN engine which offers a power output rating of 22.2kw @2,500rpm.

All the oil, fuel and air filters are easily reached inside the canopy as is the radiator expansion bottle and screen wash bottle making routine servicing easy. The engine bay is also home to the fuel filler point on the EZ36 located towards the rear of the compartment. Another neat feature is a jump start point where you can connect the positive jump lead too without the need to connect directly to the battery, this point is covered by a red rubber protective sleeve. Talking about routine servicing, the machine features colour coded grease nipple covers which signify the hours that point needs greasing, blue is every 10 hours and green is every 50 hours.

The track frame features externally guided rollers for better track retention, 4 lower rollers and 1 top carrier roller are fitted. There are 8 large tie down points on the lower frame for safer transport of the machine. Wacker Neuson offer an angle dozer with float option, but this example featured the standard blade assembly.

This unit was fitted with the extra counterweight which is an option however, Ben Dommett always prefers to supply the machines with it to improve all round balance and stability, especially with the long arm and quick hitch combination.

As previously mentioned, both these models receive brand new cabs, as with the interior, these cabs have a very Germanic look and style to them. When opening the door, I was delighted to see that when folded back in the open position, it is set well back within the confines of the counterweight safe out of the way of any potential damage. Inside the cab its all we have come to expect from the Wacker Neuson product, clean cut and very practical. A large one-piece rubber mat provides the floor, with a built-in foot rest on the left-hand side. To the right-hand side of the cab is the boom off-set pedal. In the centre two-fold down track pedals with integrated levers provide the travel controls.

The front windscreen is a two-piece affair with the lower section sliding up into the top half, which can then be stored in the roof if required. In its closed position the window can also be locked slightly ajar to allow a free flow of air if it’s raining for instance.

To the operators front right hand side is a specially dedicated mobile phone holder with a soft interior lining to prevent scratching of the screen, a neat idea for todays smartphone generation! A 12v socket is provided towards the rear of the cab so you might want to invest in a long charging lead.

Joysticks and hydraulics are from Rexroth so once again well proven stuff and very much liked in the industry. The dozer blade control is on the operators right and like many brands features the two-speed tracking button integrated into it. A radio and rocker switches are also located on the right-hand side. The familiar Wacker Neuson LED display screen is located within the right-hand console just behind the joystick and in front of the arm rest, offering feedback on the machines fuel and water temperature status. Ignition keys are now all chipped for increased security.

On the left-hand control pod a bank of 4 rocker switches are located just behind the joystick, these are the VDS selection switch, lights, safe working load alarm and the quick hitch switch. Lower down there is the hydraulic flow adjustment dial, which is used to adjust the flow rate for specific work tools that may be fitted to the machine. Also located on this side, is the manual hand throttle, this is the one thing I find a bit odd with these machines, as I am so used to finding the throttles generally located on the right-hand side of the cab, however I’m sure for the left-handers out there, this is a perfect placement!

As this is a zero-tail swing machine, there is not a lot of room in the back of the cab but once again that is the compromise you have to make with these types of excavator.

I put the machine to work shifting a pile of the famous Cotswold stone and heaping it up. After getting myself comfortable, I tracked up onto the heap where I had prepared a platform to work from, selecting power mode I dug into pile to grab my first bucketful. As you might expect the feedback through the Rexroth controls was great and although it was not the greatest material to work with the machine coped very well with plenty of poke in the dig.

The controls were smooth and responsive and a 9.5rpm slew speed ensured fast cycles during a 180-degree working arc, during which time it remained well balanced even with a heaped bucket of this heavy material. On a gloriously sunny day this little excavator was a complete pleasure to spend time on, but if I had to find one thing wrong that bugged me, it would have to be the painfully slow speed of the off-set arm adjustment, especially when you are trying to slew the upper body and the off-set at the same time, if they can get that right, this would be a machine to compete with the best out there!

Having spent an enjoyable time on the EZ36 we headed out to site to visit one of Ben’s customers who recently purchased an EZ26 model Liam Pemberton, who owns Mulburry Developments (Thornbury) ltd.

Liam whose work generally involves working on small extension projects and landscaping work had previously hired in machines, but felt it was a good time to invest in his own excavator and the EZ26 is the ideal candidate in its standard guise as it is below 2.7 tonnes and can legally be towed behind a suitable towing vehicle.

Liam’s machine has been supplied with a Strickland hydraulic quick hitch and a full set of Strickland buckets, asked for his thoughts on his new acquisition Liam said, “Well its early days at the moment, but I’ve been very impressed with it so far, on this job we had to deal with some massive lumps of concrete which came as a surprise to us in the ground, but the machine coped with it easily. We have tried all sorts of makes of excavators over the years, but not so much experience with the Wacker Neuson brand. The nice thing is I know Ben very well and he will look after us no doubt about it”.

The EZ26 shares many common features with the EZ36 including, new cab, quick hitch pipework, hammer and aux lines, security coded keys and a Yanmar engine, in this application the 3TNV76 model with a rated power output of 15.2kw @2,500rpm. Fuel filler and hydraulic oil filler points are located on the back of this machine as opposed to under the canopy on the larger machine. Maximum dig depth on the EZ26 is 2,744mm.