by Nick Drew | Fri 15 Aug 2025

Gearing up for Plantworx 2025 (Part Three)

Here we go with our last preview post for the forthcoming Plantworx 2025 show taking place at the Newark Showground on the 23rd – 25th September.

Robustrack return to Plantworx for their fifth show with a stand packed full of innovation and favourite hydraulic attachments. Visitors can expect to see popular kit including Femac flails and mulchers, Agriforest tree shears and log grabs, Malaguti compaction attachments, and Sima concrete mixing buckets.

Making its Plantworx debut is Idrobenne’s range of multi-purpose grapples, launched earlier this year. The 4/3 open finger configuration has proved a firm favourite for handling brash and clearing debris.

Also taking centre stage is the Laurini Settanta – the world’s first machine designed entirely for demolition, not adapted from another platform. Engineered from scratch for power, agility, and precision, the Settanta boasts a rear-mounted base arm, expandable undercarriage, modular design, quick coupling system and tilting cab.

The machine has been shortlisted in the ‘Best Use of Engineering & Technology Innovation’ category at the 2025 Plantworx Innovation Awards.

Davide Cerca, Director at Robustrack, said: “The Settanta is a game-changer in construction and demolition. We’re proud to offer it to the UK market and to return to Plantworx – a show that means a lot to us.”

Red Rhino is bringing two brand-new machines to PlantWorx 2025—both designed to meet the needs of today’s demolition, recycling, and compact quarrying sectors.

The Red Rhino 8000 is the biggest crusher in the company’s line-up to date. Weighing in at 18 tonnes and boasting an 800mm x 500mm jaw aperture, it fills a long-standing gap in the mid-sized crusher market. With a deep crushing chamber and a bespoke crusher box, it’s capable of outputs up to 100 tonnes per hour, making it ideal for high-volume applications.

Also on show will be the Red Rhino Electric Trommel—a fully electric, compact screening unit with synchronised feed and drum speeds for accurate material separation. Lightweight and hook-lift compatible, it’s designed for clean, efficient, and mobile operation, with two output sizes and zero emissions.

Both machines will be on display throughout the show, giving visitors the chance to see Red Rhino’s latest innovations up close.

Brendon Powerwashers will showcase the Dustec DT 400, a patented, water-powered dust and odour suppression unit designed for mobile use in tough environments including construction, demolition, and waste treatment.

Weighing just 51kg with a compact footprint, the DT 400 is easily moved around site and requires no electrical supply. It pairs with standard cold water power washers (100–250 bar, 12–25 L/min), using a single nozzle to create a fine mist that efficiently suppresses airborne dust and odours. The water-powered fan design means 60% of the water drives airflow, while the rest is atomised—minimising waste and avoiding high-pressure risks.

The DT 400 operates up to 75 metres from the washer and switching between dust and odour control requires only a nozzle change. A bolt-on model (DT 400BM) is also available for mounting to Brendon’s Bowserwashers, enabling over three hours’ run time per tank.

Designed for flexibility, low emissions, and improved site safety, the DT 400 is ideal for dynamic site conditions—from asbestos removal to general odour control.

Marshall’s Industrial, the official UK and Ireland distributor for HD Hyundai Industrial Engines, will be at PlantWorx 2025 with a full line-up of power systems built for demanding applications.

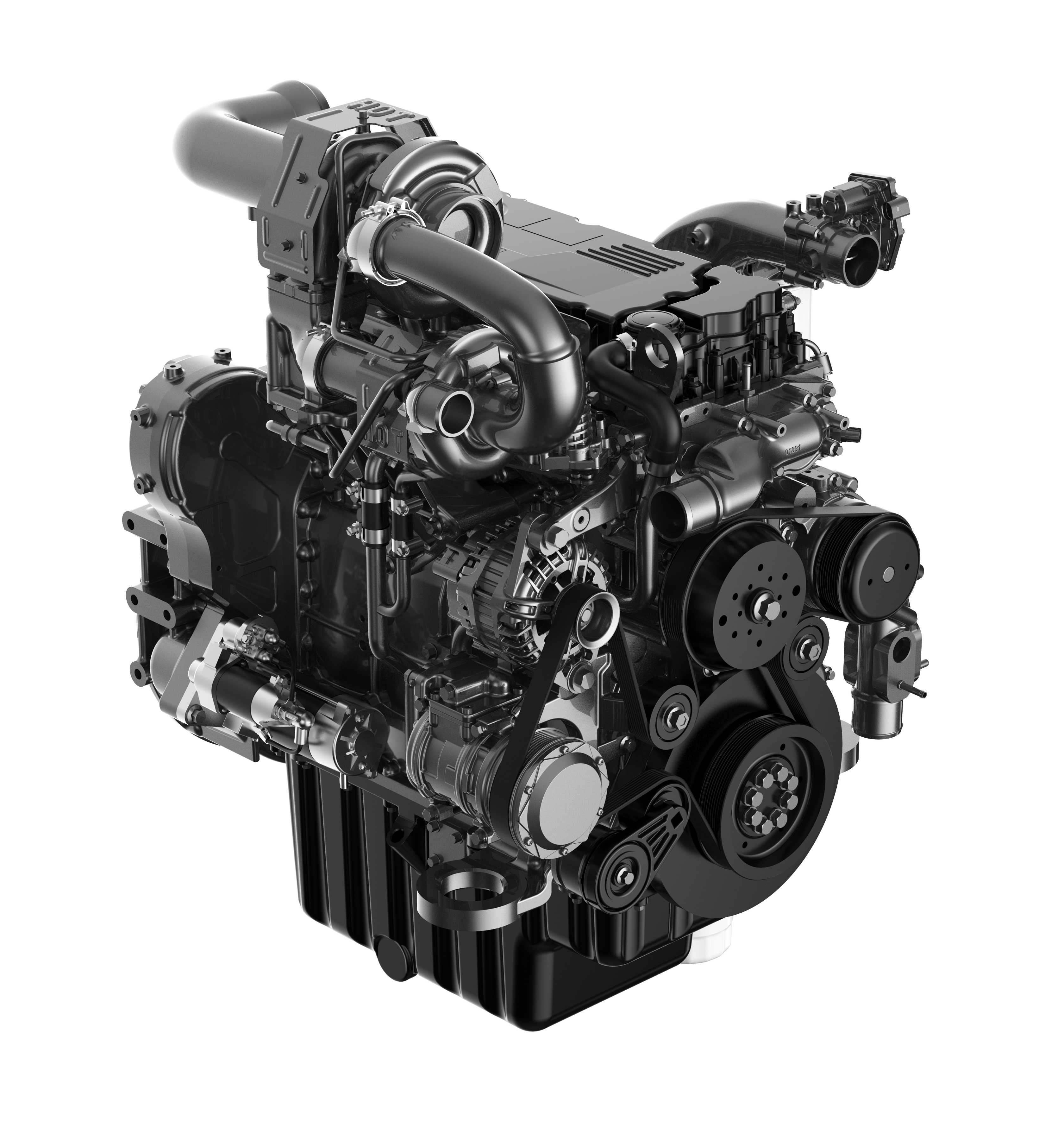

On display will be HD Hyundai’s Stage V and Tier 4 Final certified engine range, including the ultra-compact G2 Series—designed for fuel efficiency and ease of maintenance—and the award-winning DX05 and DX08 engines, recognised for their performance in 5-litre and 7.5-litre formats.

Visitors can also view the HX12, an 11-litre hydrogen-powered engine built for future low-emission applications, and the e-Powerpack range, developed to support cleaner, longer-running electric equipment on site.

Conquip will unveil four new products at PlantWorx, each developed in response to real challenges faced by site teams.

The Smart Fuel Tank is a solar-powered, app-controlled fuel storage unit designed to prevent theft and monitor fuel use by user, site, or vehicle—ideal for flexible site placement and reducing wastage.

The Safety Station is a durable, weatherproof safety hub for site briefings and emergency information. The base unit includes a whiteboard, pinboard, and fold-down shelf, and can be tailored with extras to suit individual site needs.

Conquip’s Compact Concrete Washout Unit captures, treats and reuses wastewater from concrete trucks and tools. A filtration bag collects large particles, while built-in treatment neutralises pH, allowing safe disposal or reuse.

The Compact Chain Storage Rack helps keep lifting gear secure, dry and organised, with overhead hooks, optional lockbox, and a waterproof certificate holder—all in a compact footprint.

These innovations will be on display at Conquip’s stand (DA-13). Visitors can also try the popular ‘Skip Tip’ Challenge in the Operator Challenge area.

For those focused on sustainability, Conquip’s Fuel Eco-Hub will be featured in the CPA’s Sustainable Site Solutions Spotlight.

Our friends at Worsley Plant will introduce two new products to the UK market at PlantWorx 2025, both designed to improve efficiency on site and reduce handling time.

Making their debut are the Rotar RSS X-Series Scrap Shears, engineered for demanding demolition and scrap processing work. With reinforced nose blades, improved jaw alignment and high cutting force, the X-Series can operate at pressures up to 380 bar. Models are available to suit carriers from 9 to over 75 tonnes, offering strength and reliability across a wide range of applications.

Also on show is the Dynaset HRVB Hydraulic Recycling Vacuum Bucket—a compact attachment that transforms hydraulic power into a vacuum and air blow system. It’s designed for collecting lightweight waste such as plastic, insulation, or packaging debris, making it ideal for site clean-up, railway and road maintenance. The HRVB helps reduce manual labour and disposal costs by speeding up recycling and waste handling on the job.

Both products reflect Worsley Plant’s ongoing focus on productivity and jobsite innovation. Attendees can see both in action and speak to the team about where they fit into current workflows.

This weeks Plantworx preview posts represent only a fraction of the exhibitors who are attending, with over 300 companies showcasing products there will be something for everyone at the show, we will see you there!

Register now for free at https://plantworx.yourticketpurchase.com/p/visitor and be part of the UK's biggest working construction show of the year.

There’s also a full exhibitor list and a floor plan to plan your visit – www.plantworx.co.uk.