by Nick Drew | Fri 12 Sep 2025

Young Gun Turns to the Blue Side

Harry Dale (25) who hails from the village of Chiselborough in South Somerset, has always been very much a ‘hands on’ type of guy and upon leaving school he had no desire to go on to further education, preferring instead to get a job in the traditional manner.

Harry was fortunate to be offered an apprenticeship with long established and respected Swindon based groundworks and civil engineering business Tithegrove Limited, where taking full advantage of the opportunity, he worked his way up through the ranks on the ground. After finishing the 12-month apprenticeship he was assigned to a groundworks gang and shortly after he was sent over to Chard in Somerset to start a fresh new site and at the age of 19 found himself being made up to site supervisor status, the youngest to hold that position on the company.

On this job Harry was sent an owner-operator Phillip Wilcox who had his own Doosan DX140LC hydraulic excavator. Harry said, “Phillip taught me an awful lot, a very skilled operator and just watching him everyday was a lesson in itself, we done everything on that job from stripping the topsoil, the roads, deep drainage, digging and concreting foundations, block work and retaining walls so we did a bit of everything really, which was all good and invaluable experience”.

Harry continued, “I also think what was good about the supervisor’s role for me, was having the responsibilities of deadlines, and obviously learning to work with the NHBC with how strict their rules are, and working with other contractors, it was a quick learning curve on taking on responsibility and having respect for other people, something I feel we don’t see so much of nowadays with guys coming up through the ranks”.

With an ambition to start out on his own, Harry started off as Harry Dale Groundworks and Services back in 2020 with the one 14-tonne machine which he had bought a share in with Phillip Wilcox, some time later he purchased the entire machine and became the sole owner. The extremely tidy Doosan has amassed over 19,000 hours on the meter but has been well looked after over the years, and is still a very tight and capable machine.

Towards the end of 2021 early 2022 Harry was approached by a small developer who wanted them to put in some large concrete block roads, so it was around that time that he decided to reset the business as Harry Dale Groundworks Limited, because they were taking on bigger jobs, which in turn meant higher risks, so he felt he needed to protect himself.

The groundworks company undertakes a wide variety of work from greenfield site work, right up to building private bespoke dwellings for individuals, right from the foundations, right up to blockwork and masonry finishing, so in effect a one-stop-shop complete contractor.

Being based in rural Somerset, another sector they have moved into is agricultural construction groundworks, undertaking concrete works on the grant schemes for local farms, and being well known in the area with a great reputation for quality work, word spreads very quickly so the work kind of rolls on from that.

The business is a tight knit affair with Harry undertaking virtually everything on his own, from paperwork to manual labour, and machine operation and maintenance, he does gainfully employ one other employee, Ollie Leach who does groundworks and machine operating, on some of the larger jobs like concreting projects, Harry has good pool of self-employed contacts he can bring in for extra man power as and when required.

Most recently Harry has been adding some smaller machines to his fleet as he explained, “I had been toying with investing in a 1.5-tonne machine for some time, having previously had a Takeuchi model on a long-term hire contract, I felt it made sense to purchase one myself. I was working locally and spotted a utilities company running a 1.5-tonne Kobelco, I kept seeing this SK17SR-7 machine and the more I looked at it, the more impressed I was, I really liked the design of the canopy with no near side front pillar, and thought what a great idea, not only does it make for easier access up into the seat with me being 6”.4, it also offers greatly improved visibility to the work area, so I rang Molson’s in Avonmouth as they had previously been in touch, and the sales rep responded very quickly, and to be perfectly honest, I didn’t even try one out!

The rep asked if I wanted a quick coupler, with me expecting it to be one of those cheap and cheerful spring hitches, but he said no, you can have a Geith fully automatic hydraulic hitch, so I thought wow yeah we will have one of them, and my god its been amazing in terms of time and labour savings, in addition with manual bucket changing now being outlawed on larger sites it was a bit of a no brainer really.

I have been really impressed with the small machine so far in every aspect and that is why I have decided to add the larger SK26SR-7 to the fleet”.

The new machine has been highly specced by Harry to include a Geith tilting coupler and a heavy-duty rotary grab which has been supplied by Keen Attachments, with additional third line pipework, and a full set of Strickland digging buckets. In addition, LED work lights have been fitted front and rear and stylish blue and white chevron signage on the additional counterweight finish it off nicely.

We paid a second visit to see the new arrival at work on the site of a new private dwelling in Harry’s village. The SK26SR (Short Radius) model which has a standard operating weight of 2,600kg (+250kg with the extra counterweight) was launched in 2023 alongside its larger brother the SK28SR-7 and features numerous improvements over the previous models in this weight class.

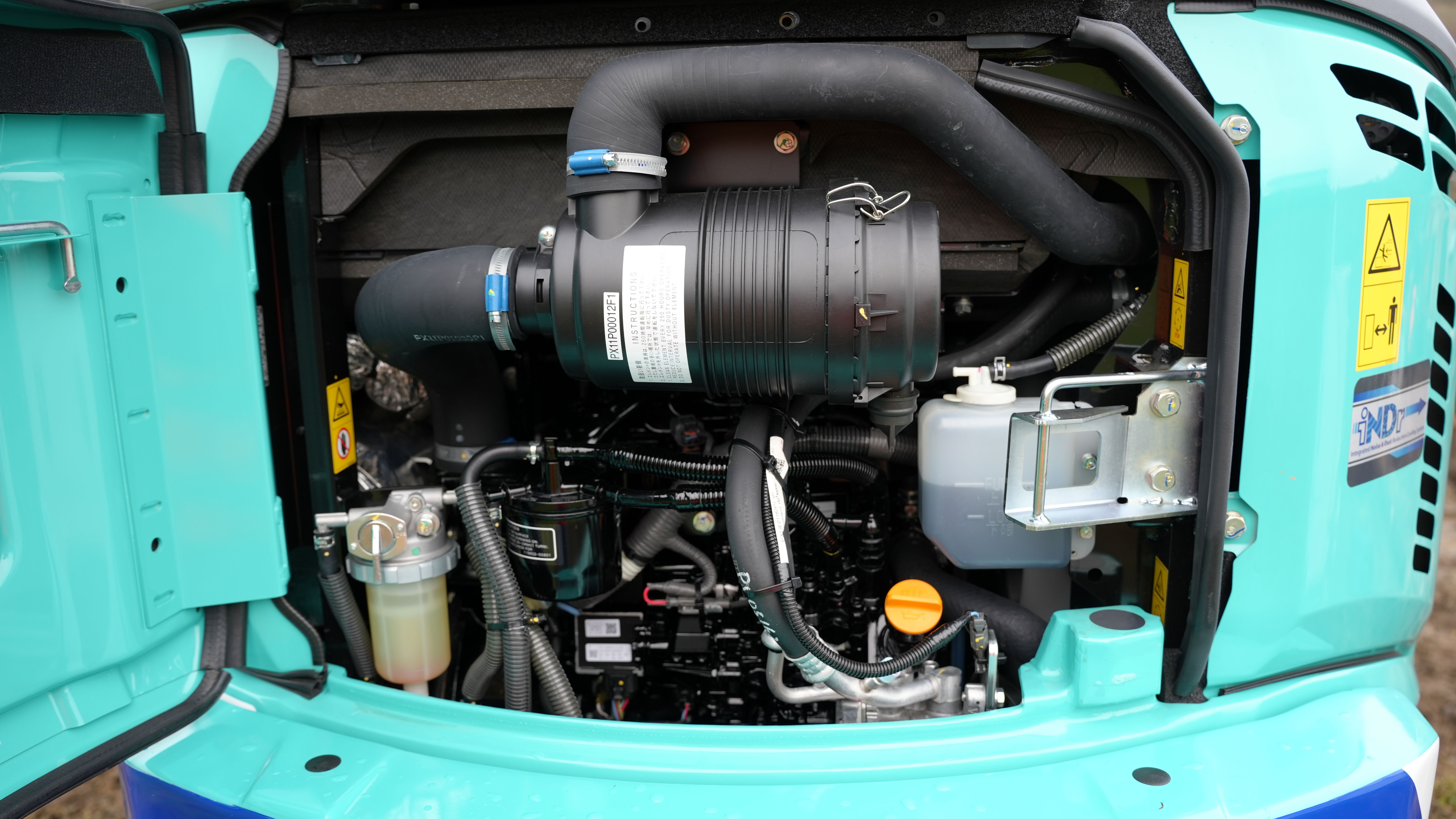

Popping the bonnet and as one would expect we discover more Japanese quality in the form of the well proven Yanmar 3-cylinder 3TNV88 diesel engine which has a power output rating of 18.9kW @2,400rpm and complies with EU Stage V emissions regulations. Air, oil and diesel filters are all nicely grouped for ease of changing at ground level during service intervals.

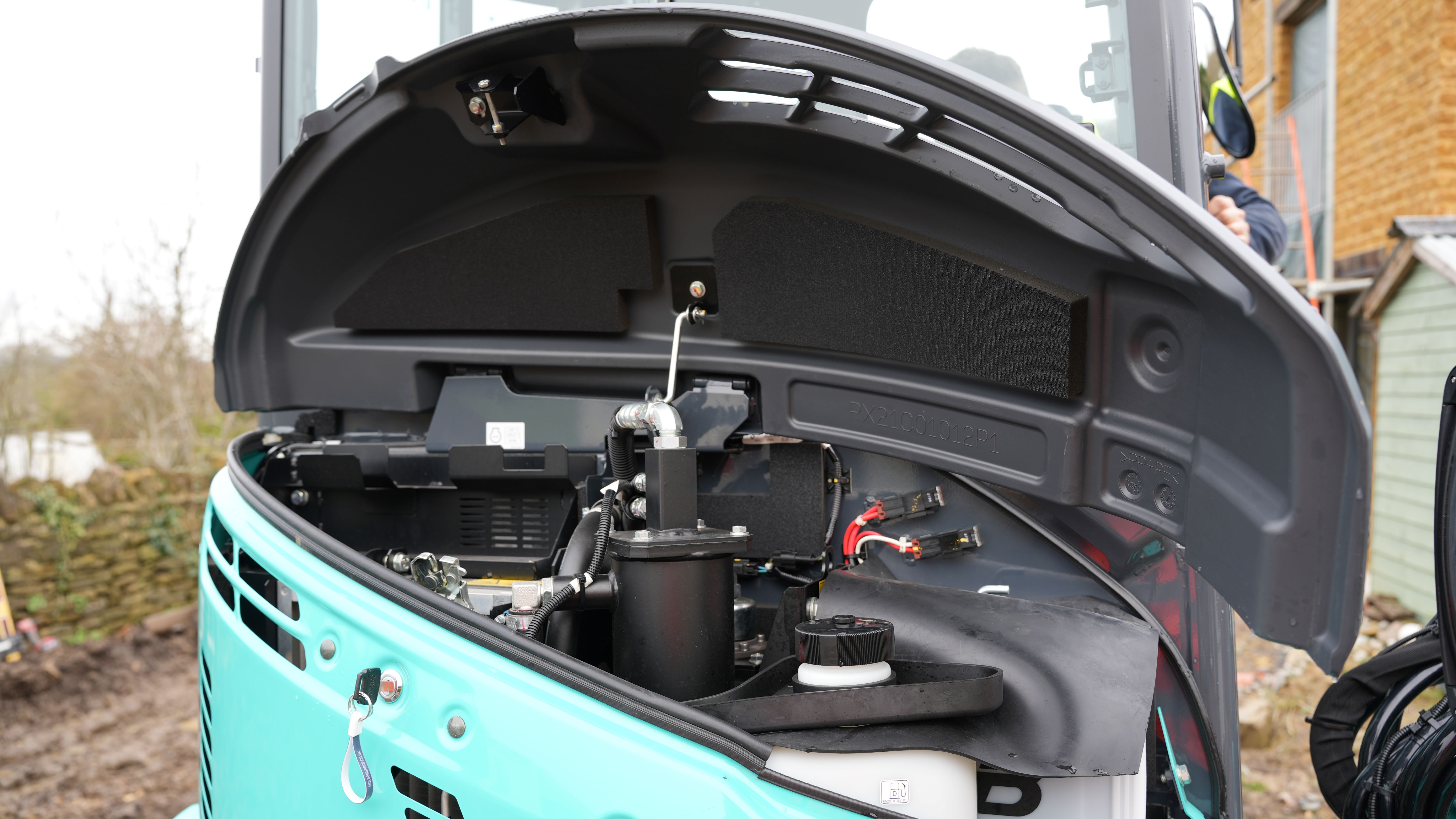

On the offside a large composite bonnet raises up to allow access to the diesel tank, battery and Kobelco’s patented iNDr (Integrated Noise & Dust Reduction Cooling System) and associated filter designed for ease of cleaning.

I have not spent anytime on the Kobelco mini excavators before, so I was delighted to be invited by Harry to spend a bit of time on the SK26SR-7. Climbing up into the cab through a very wide door space, I have to say I was impressed, I think all the major manufacturers have seriously upped their games in terms of operator comfort and automotive design features and this Kobelco did not disappoint.

As ever the Grammer suspension seat proved to be extremely comfortable and the level of trim all around the cabin was top drawer. All the levers fall nicely to hand and switches and buttons are LED illuminated which is great in all light conditions, but even more so on a dull day in January!

There are various storage cubby holes dotted around the cab, and that all important cup holder at the front for the morning brew. Heating and cooling super effective thanks to the air conditioning system, something that is more often than not an option in this weight class. There are multiple adjustable air vents located around the cab to provide a good circulation of hot or cold air flow. Fans of the fresh air can choose to have either of the offside sliding windows open, or the front screen, or secure the main door in the open position, which although looking slightly vulnerable in the open position, does actually remain within the swing radius of the machines upper body.

The 3.5-inch multi-colour display monitor provides important machine information, including fuel and water temperature, service intervals and adjustments to the hydraulic oil flow to the attachments (Hydraulic Flow Adjustment). You also find the work mode selection button on the screen, two modes are provided, one for ECO-mode and one for full power, while the auto deceleration function saves fuel and less noise impact on the environment.

Nice T-Bar track levers with decent sized integrated track pedals are provided, but for those who prefer not to use tracking levers, they are easily removed. A DAB+ radio with FM/AM & AUX & USB, Bluetooth and hands-free telephone function is fitted, in addition to a dedicated smartphone holder with integrated USB/AUX port.

I put the machine to work for around 20 minutes, and found it to be a very capable piece of kit, plenty of power and smooth as silk on the hydraulics, in fact exactly how Harry had described it to me, and I wasn’t disappointed.

With a track length of 1,980mm and a width of 1,550mm the machine felt very well balanced throughout the range of movements even with a full bucket of seriously damp topsoil, it was never unsettled. I also appreciated the lift height on the dozer blade which at 440mm kept it out of the way when climbing up the heap with the blade to the rear. Talking of the blade, when performing dozing work, its curved shape assists in the rolling forward of the material being pushed.

Though I only spent a short time on the SK26SR-7, its not hard to see why they are becoming a popular choice across a wide range of contracting sectors.

Harry further demonstrated the machines flexibility by fitting up the grab, which I’m sure will become a very valuable tool in his arsenal of attachments going forward.

Harry has been impressed with the level of service provided by Molson’s so far, commenting, “I really went with Molson’s because they are more of a nationwide based company, and with my work, although we are largely Somerset based, we sometimes have jobs as far aways as London and Lincolnshire, so I wanted the peace of mind that we would be covered if a breakdown occurred.

For example, we did have a little problem with the new 1.5-tonner when we first got it, but within an hour the Molson engineer was out to us and it was back up and running in record time, with that level of back-up, you just can’t fault them. Another example is when you visit their premises in Avonmouth, the level of resources they have there is impressive, if just installs confidence for me personally”.

With the exception of an accountant who takes care of the bookkeeping, incredibly at the moment this young man’s business is entirely run by Harry himself, from quoting to invoicing, to paying suppliers and staff Harry does it all, and in between all that, he is out on the job putting in the hard days slog, so it’s a 24/7 scenario for sure.

He’s a likeable lad with a good work ethic and well known in his village, which all bodes well for the future of Harry Dale Groundworks Ltd.

3 issues of Earthmovers for just £3 - click here