by Nick Drew | Wed 18 Dec 2019

Finnish Army Knife

Taking another look back at one of my articles previously published in Earthmovers Magazine and bringing it to life on the internet, featuring my visit to Lannen Tractors in 2017.

Multi-faceted Finnish construction equipment manufacturer Lännen Tractors Oy celebrated a significant milestone in 2017 which was their 60th year of producing backhoe loaders which they refer to as multi-function machines.

Although relatively unseen in the UK market thus far, the company which is probably best known for the aforementioned technologically advanced, articulated backhoe loaders has more strings to its bow as I was to find out during a visit to the factory in Loimaa, in the South West of Finland and out on jobsites across the region.

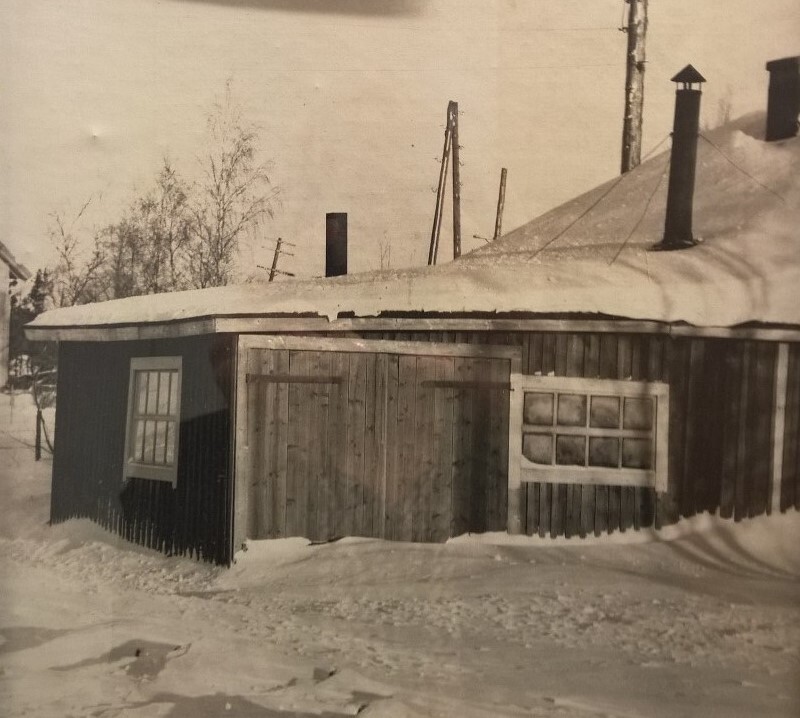

Like so many of today’s machinery manufacturers the Lännen Tractors story stems from very humble beginnings. The business was originally founded in 1952 by a local man called Teuvo Syvänen who set himself up as a self-employed blacksmith working out of the company’s first premises which was a 4 x 4 metre wooden shed. Over the years the size of the premises increased with the current factory site being established in 1973 and initially covering an area of 1 hectare. Following expansion in 1980 the facility in Loimaa has since doubled in size.

The 50’s and 60’s were heady times for engineering company’s developing attachments for tractors on a global scale and in 1957 Lännen launched a front loader attachment for tractors using the unlikely brand name of the James 50. This was followed in 1964 by the James 600 which featured a backhoe and front loader, jointly married to an industrial tractor, but perhaps the most important milestone was in 1982 when the company launched what they claim to have been the world’s first articulated steering backhoe loader model the James 92.

Photo: Courtesy of Maskinisten.Net

The group of companies today incorporates Lännen MCE Oy (Multi-function Construction Equipment) Lännen Tractors Oy and Aquamec Oy with production of the machines taking place in its factory in Loimaa in Finland, with the Swedish subsidiaries being Lännen Tractors AB, who distribute the range in Sweden and Lundberg Hymas AB who produce the compact tool carriers at their factory in Skellefteå in Northern Sweden. The company as a whole markets its various products to over 70 countries globally thanks in part to the success of the manufacturers Watermaster range of shallow water dredging machines. Production floor space across the two factories covers 25,000m2 and offers employment to around 120 employees.

A tour around the factory floor at the Loimaa facility revealed a familiar pattern too many other factories I have visited. Production starts with some cutting of steel followed by a combination of manual welding and robot welding for the more extensive part of the operation. As the various heavy part sections head down the production line a team of small part component collectors deliver their trolleys loaded with spares designated to the corresponding machine located by its serial number on the assembly line. This means that the machine assembly team don’t have to leave their stations to look for parts thus ensuring they remain focussed on the product and ensuring the quality of the build.

Blue chip components like axles by ZF, transmissions by Dana Spicer, Bosch Rexroth and Danfoss hydraulics and engines from Agco are installed as the machines take shape progressing down the line as I was shown with an example that was destined for a rail customer in Russia. The machines hydraulic systems are tested as it progresses down the line and the quality control processes throughout the build-up looked very impressive. The cab shells come in two different designs and are made by another Finnish supplier with internal components added during the assembly process. When fully completed the machines are road tested to get them up to working temperature and put to work on the digging plot adjacent to the factory as they check for any potential leaks.

So just what makes these backhoe loaders so special I hear you ask, well I was keen to find out more too and embarked on a series of site visits to see the machines in action. The main emphasis from the team at Lännen was that these are not your conventional backhoe loader as we would know it in Europe, but more of a multi-functional piece of kit that can act as a tool carrier at both ends using a seemingly endless range of attachments. In true Scandinavian style the only thing holding you back would be a lack of imagination as in a whole host of applications the possibilities for the end user are limitless.

According to Lännen Tractors Sales Director Juhani Kaitila these multi-function machines have long been embraced in the Scandinavian domestic market which includes Finland, Sweden and Norway and they are well proven in a wide variety of applications such as utilities work, urban construction, infrastructure & building work and on the railways, Juhani said “Customers are re-thinking the way they tackle jobs by using less numbers of conventional equipment and replacing them with one multi-function machine which offers more mobility and versatility whilst being more productive but with less environmental damage, our machines are fast, powerful and agile and offer so much more than any conventional backhoe loader”.

Juhani certainly had a point, as during my travels around Finland I saw many examples of Lännen machines of varying ages at work in a wide variety of job applications.

On our first site visit to see a young Lännen customer I quickly began to get a better understanding of the concept. At just 29 years old Joni Vento is something of a fan of the Lännen machines and has just taken delivery of his 3rd which is the all new 8800K model. Joni had previously ran two second hand Lännen units, starting out on his career with a year 2000 model 860S, replaced later by a 8600C model which was built in 2006, but this 8800K machine is his first brand new one and from his beaming smile it was clear to see that he was delighted with his new investment.

Based in Rymättylä in Southwest Finland Joni’s main sphere of work involves the excavation for and laying of electrical cables. As in many parts of the world, in Finland it’s a busy time for removing often vulnerable overhead power lines and putting them into the ground. On the weekends Joni often takes on more private work digging and loading, or forest thinning work using his harvester head. During the winter months he like many others in the Nordic regions, takes on snow clearing work.

Joni was keen to show us around the new mount, a quick release of the bonnet reveals the 4 cylinder, turbocharged and intercooled Agco 49 AWF diesel engine which is Stage 4 Final emissions compliant and offers a power output rating of 173hp (127kw) @1,900rpm and features improved torque over previous models of 740Nm @1,000rpm. Through the use of diesel fuel additive (AdBlue) emissions levels are met without the need for any recirculation of exhaust gasses (EGR) or a diesel particulate filter (DPF). One thing I noticed straight away was just how quiet the engine was even with the bonnet raised, according to Lännen noise levels inside the cab are only 67.5 LpA/101.5 dB.

Walking around the machine it’s clear to see that it has a decent footprint on the ground with a long wheelbase of 2,700mm, but for a long machine it’s no slouch in confined areas with its articulated steering offering a turning circle of 42o. Joni also commented that it’s very lively on the road with its hydrostatic transmission and 2-stage “Power Shift” electric control it offers a top speed of 45 km/h making it great for moving from job to job.

The machine is equally at home on the uneven terrain often encountered on the jobsite too, sat on 620/60x34T459 front and rear Trelleborg tyres, the machine has very high ground clearance and add into the equation +400mm of frame oscillation its superbly equipped for any off-road situation.

The machine’s automatic control system for the aforementioned frame oscillation, AOC, monitors the oscillation of the frame and the movements of the backhoe, and optimises the operation of the oscillation lock, this clever technology ensures stable operation when travelling over uneven ground.

Taking a look at the backhoe, which can apparently be removed and replaced with a counterweight or other attachment if required. Joni has gone for the optional knuckle boom configuration and as we would expect in a Scandinavian territory his machine has been supplied with a tilt-rotator which on this occasion is from Swedish manufacturer Engcon. Standard digging reach on the 8800K is 6,830mm with a maximum digging depth of 4,970mm but Joni’s machine will probably gain a bit more with the tilt-rotator fitted. Joni has also had an SKF Multilube automatic lubrication system fitted which is a great addition to any machine and of course it would not be a Scandinavian machine if it didn’t have some “pimp my ride” style bling on it and not to be outdone Joni has had a good selection of LED work lights and flashing strobe lights fitted.

I was invited into the cab to take a look and to try out the machine myself. We have all spent time in backhoe loaders and excavators over the years but nothing could have prepared me for what I encountered in the cab of the 8800K, on the left hand side of the cab on the pillar and console on the right hand side of the seat there were more buttons and switches than you would find on the “Starship Enterprise”, not saying that’s a bad thing of course as I’m sure each button and switch is there to serve a purpose on this high tech piece of equipment, but there was just too much to take in especially on such a flying visit and there is no doubt you would need to spend a few hours on one of these to fully understand all the various functions.

I was briefly shown some of the controls and was then let loose with the machine firstly using the backhoe. As I had experienced once before on a Swedish Huddig machine, the joystick controls built into the seat on the Lännen were probably some of the finest I have ever used, extremely precise, comfortable to use and very responsive to my movements. As seems to be customary with these machines in Scandinavia I was advised to operate the machine without the jacklegs down and I was pleasantly surprised to see how well the machine remained balanced throughout the movements of the arm even when outstretched at 180o, even in the dig this machine which tips the scales at around 13 tonnes remained rooted just sat on its wheels which was impressive to say the least.

Visibility to the front and all around is excellent thanks to a mass of glazing, but being sat on the rear section of the machine does give a feeling that the front bucket is a long way in front of you and I found it difficult to see the corners of the front bucket. The steering wheel column folds in two places as well as a wheel height adjustment feature so you can achieve that perfect driving position, ideal for those long cold Scandinavian winter nights shifting snow!

It was then time to let Joni take back control of his machine but not until he had demonstrated how the machine can be driven when facing rearwards by using the joystick controls. As if it was needed this quickly demonstrated how the function can speed up any work place practice, as Joni started to backfill the trench he had excavated earlier for the cable. With the said cable in place in the trench partially buried with some fine soil, in true Scandinavian style Joni proceeded to pick up the marker tape in the corner of the bucket and travelled the machine backwards while lowering the tape into the trench, a clever bit of showmanship maybe but I suspect it’s the norm to do such things in these parts, after all, why do things manually when the machine can do it all for you.

Energy business ELTEL currently has the contract to maintain most of the electric railways in Finland. Part of the contract involves the replacement of electrical overhead powerlines in the Capital city of Helsinki. The company’s primary machine for this work is a Lännen 8800i, the predecessor to the 8800K which is powered by Stage 3B Agco engine. This machine is now 2 years old but has only amassed 1,600 operational hours during its working life.

This machine is also fitted with the alternative cab design which features a curved glass design for improved up ward vision. This cab design with bullet proof fixed glass is also used in Lännen machines supplied to the forestry industry.

These machines really do define the title of a Swiss Army Knife or in this case the Finnish version. The machine is fitted with Lännen’s 1900 telescopic boom crane jib which is mounted beneath the Engcon tilt-rotator. The fully extendable work platform can elevate operatives to a height of 17m and from which you can operate the machine functions in complete safety as it will not allow you to operate outside of the machines safe working envelope. When mounted on the rails this machine uses the drive from its wheels to travel down the track with the rail bogies at either end acting as guides.

I think it’s fair to say that the Lännen machines are not cheap, but premium quality comes at a price which is often the big driver in purchasing decisions in the UK market. However, these machines could appeal to the younger more forward thinking generation like those that have already seen the potential of tilt-rotators in our home market. Times are changing in the way we do things with less machines being brought in to do the jobs replaced by a more versatile machine with a host of attachments, it will be interesting to see who is the first to see the value in these all singing, all dancing machines and buy one in the UK.

Watermaster and Lundberg

As previously mentioned the company has other machines in its portfolio including the Watermaster amphibious multipurpose dredger. This strange looking piece of kit looks like it has come straight out of an episode of Thunderbirds, but it’s a well proven concept with many examples now operating around the world in over 70 countries.

The machines which are also assembled in Loimaa can operate on dry land and out in water to a depth of around 6 metres. The Watermaster can be used with a wide variety of quick change attachments and can be deployed to deepen shallow waterways, remove invasive vegetation and rubbish build up and to assist in preventing floods.

A common sight in the Scandinavian regions the Lundberg range of compact multi-function tool carriers offer end users more choice in how they do their work. Once again the focus is on doing more with less, as this one articulated compact loader machine armed with an arsenal of attachments can be kept busy all year round performing tasks such as snow clearing, gritting roads and footpaths, brushing and washing pavements and tarmac areas after the winter months, and cutting brushwood just to name a few.

I for one came away from the Lännen facility truly impressed by the diversity of the company and its range of products. It was a real eye opener to see these amazing pieces of equipment and I will be keeping a look out for them in the future.

We have around 8 x Lannen 2020 wall calendars to give away thanks to our friends at the factory in Loimaa. To be in with a chance to win one for free head over to our Digger Man Blog Facebook group and simply like and share the post to go into the draw. (UK residents only)