by Nick Drew | Wed 02 Nov 2022

In the Cab at Bauma with Liebherr

No Bauma is complete without a large Liebherr Mining hydraulic excavator sitting on the stand, and Bauma 2022 was no different as the German manufacturer took the wraps of its new R 9300 Generation 8 model.

Although nowhere near the largest Liebherr hydraulic excavator in the range, and looking somewhat dwarfed sat beside the T 274 Trolley Assist dumptruck the R 9300 is still an impressive piece of kit, replacing the outgoing R 9250 model in the 250-tonne class sector.

Built in the company’s new mining excavator factory in Colmar, France, the Generation 8 model will enter serial production in 2024 following an intense validation and testing period.

Setting new standards in the mining industry, the R 9300 is equipped with Liebherr Assistance Systems. These advanced on-board applications are designed to support operators to become more efficient through analytics and actionable insights from live data.

Liebherr’s first step in hydraulic excavator automation, the Bucket Filling Assistant, is available as an option for the backhoe version of the R 9300. The Bucket Filling Assistant is an adaptive or semi-autonomous digging function which allows for easier and faster bucket filling, improving overall productivity and reducing operator fatigue.

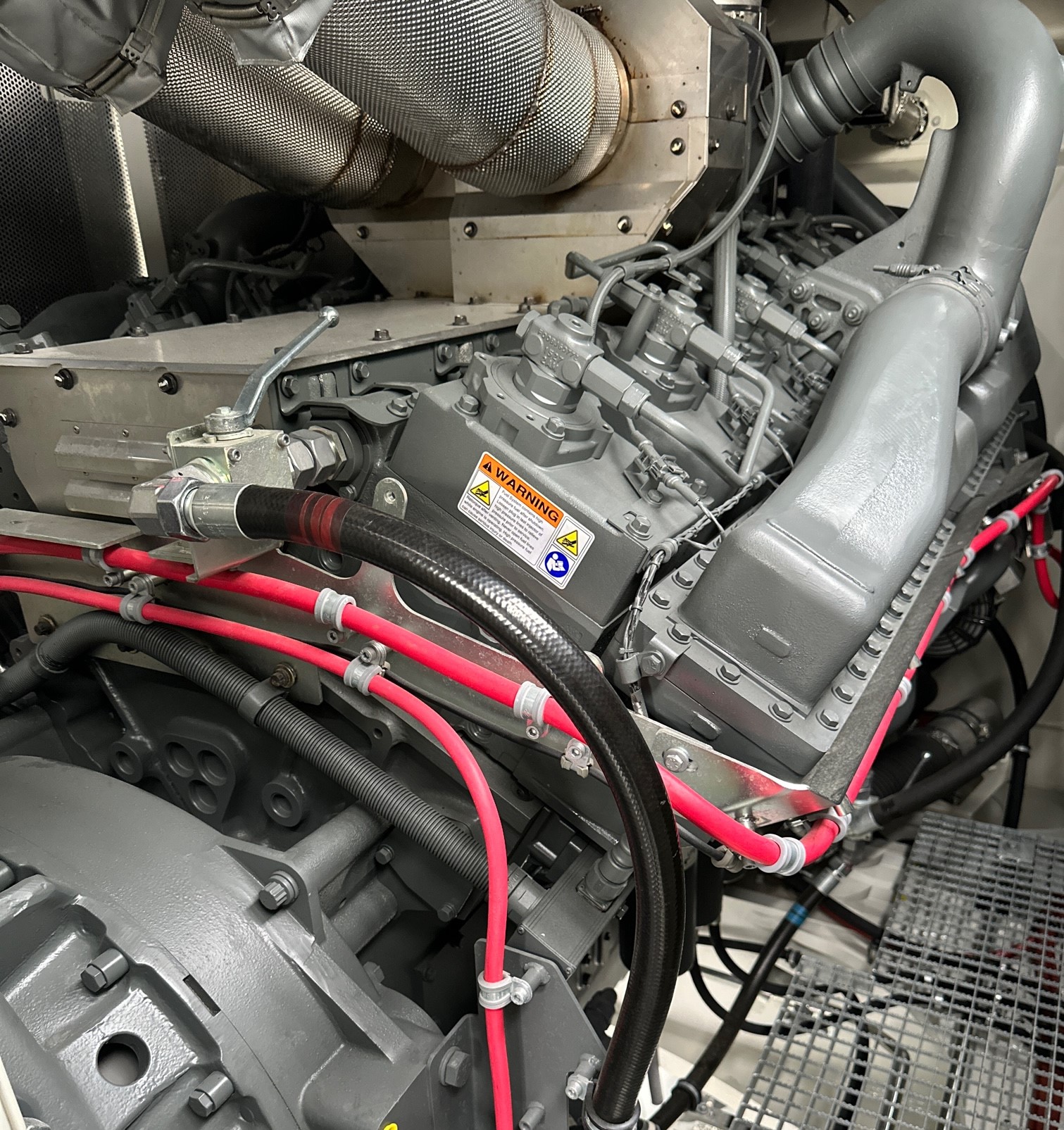

The R 9300’s engines are available in FCO and US EPA Tier 4/EU Stage V (with SCR after-treatment technology). Further, the R 9300 can be configured in either diesel or electric drive, with the electric drive able to take advantage of the Liebherr cable reeler solution.

A fully autonomous solution with up to 300m of length, the cable reeler enables management of the cable during operation and provides better mobility of the machine, optimises safety, and reduces the number of crew required for cable handling.

Designed for all mining applications, the R 9300 is built for 60,000 hours design life which represents an increase of 33% when compared to the R 9250 model. With component lifetime also aligned to this improved design life and strong parts commonality between the other Liebherr excavator models, the R 9300 offers ease of maintenance for customers. The lean design development of the R 9300, including components from the existing portfolio, promotes machine effectiveness and efficiency in performance while reducing lifecycle costs.

In standard backhoe configuration, the R 9300 comes with a 16.5 m3/21.6 yd3 bucket to deliver an ideal truck/shovel match with Liebherr mining trucks. The excavator loads 180 t trucks in seven passes, 130 t trucks in five passes, and 100 t trucks in four passes. Also available in face shovel configuration equipped with a 16 m3/20.9 yd3 shovel, the R 9300 is suitably matched with 180 t, 130 t, and 100 t haul trucks.

Integrating the latest cabin generation, the R 9300’s cabin offers first-class comfort and safety for operators through enhanced cabin ergonomics as well as large touchscreens and a new control panel design.

I was fortunate enough to be invited up into the cabin of the R 9300 during one of the demonstrations that took place on the stand numerous times each day.

It was a very memorable experience for me personally, and I would like to thank Swann Blaise and his team at Liebherr Mining for the opportunity. On this occasion I wasn’t able to get on the controls myself, but it is in my mind to take a trip to Colmar one of these days to try one of these large excavators out for myself on the demo plot there.

Checkout my video from the cab below.