by Nick Drew | Wed 18 Feb 2026

Taking a Closer Look at Hyundai’s HX360 and HX400 Excavators

Hyundai’s new Next-Generation hydraulic excavators really are a quantum leap ahead from their previous models, as I discovered last year during my trip to Belgium to spend time in the seat.

The new machines were presented to the public for the very first time at the Bauma Trade Fair in Munich last April, with the 36-tonne class HX360L being the focal point of the daily live demonstrations on the stand, while the 40-tonne HX400L took centre stage as a static display with a demolition style straight boom.

That same HX360L, along with other new HD Hyundai Construction Equipment machines, were made available to a select group of actual machine operating journalists at a construction industry training school not far from Hyundai Construction Equipment Europe’s European facility in Tessenderlo, Belgium.

The machine along with the HX19E electric mini excavator, HD130A dozer, and the HL955L wheeled loader had previously been made available for European dealer technical training, and so it made for an ideal opportunity for some media coverage of the machines.

Being an excavator man, I was naturally drawn to the HX360L from the start. Walking around the machine and one cannot but fail to be impressed with the new styling, which I would describe as dynamic and bold, but these machines are much more than some kind of cosmetic makeover, they are a totally new design and brimming with the latest technologies.

Climbing up onto the upper structure you are guided by the standard fitted hand rails, enabling three points of contact on the initial climb, this example didn’t have the full wrap around boxing ring (fall from height protection) but one would imagine UK spec ones will be supplied with that set-up.

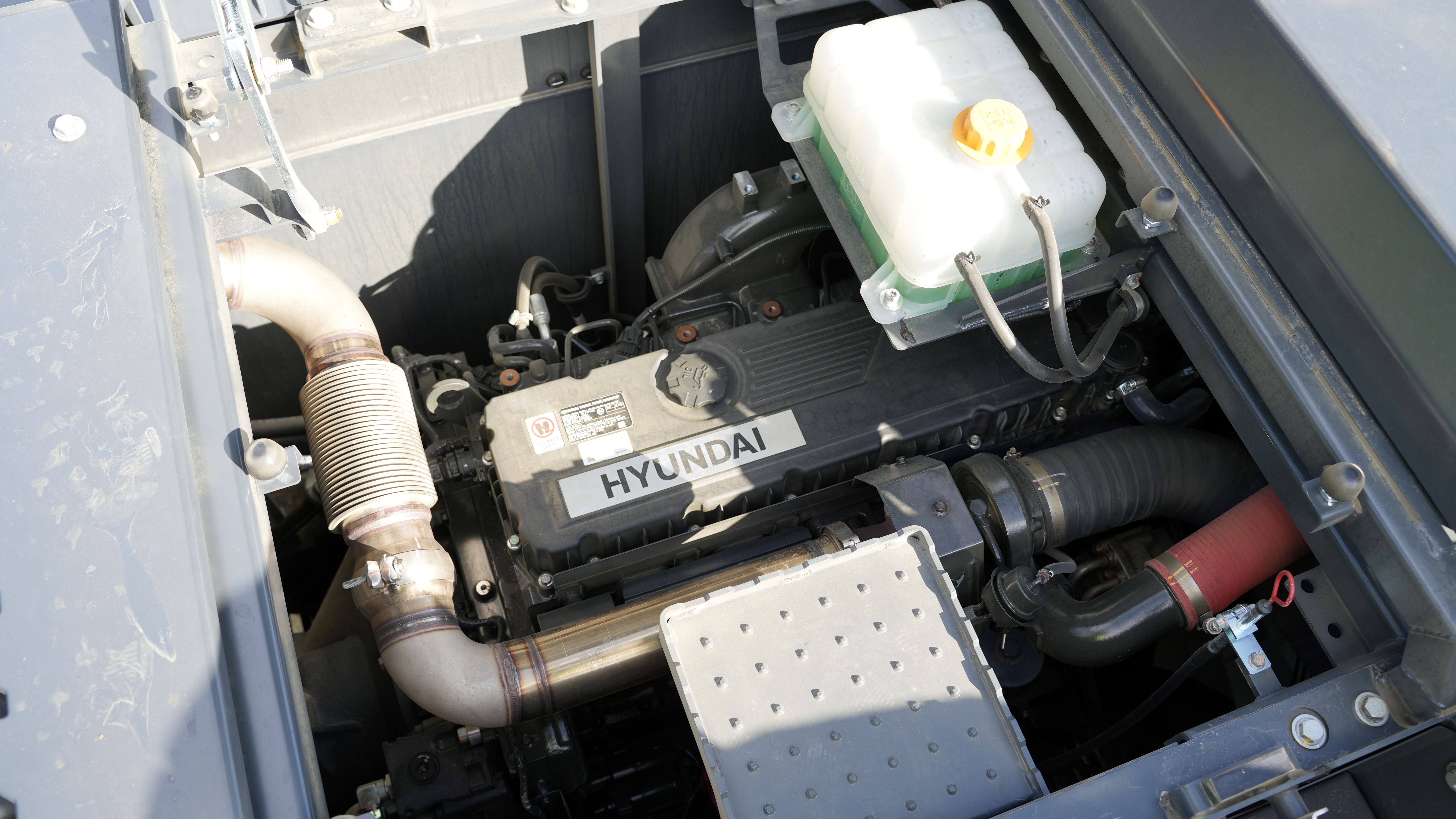

Popping the engine bonnet we notice a big change, no longer home to a Cummins power pack, the new machines feature Hyundai’s own DX08 diesel engine, which was recently awarded the prestigious title of Diesel of the Year 2025.

This clean sheet design six-cylinder EU Stage V/Tier 4F emissions compliant engine has a maximum power output rating of 227kW (304hp) @1800rpm, and an impressive and powerful 1,230Nm of torque @1200rpm. It features a two-stage turbocharger, which Hyundai suggests offers a 23% higher power output than previous generation engines. In addition, this engine is said to offer an 8% fuel efficiency gain over the old powerpacks.

These engines have been specifically tailor made to meet the arduous demands of powering a hydraulic excavator. In terms of maintenance, oil filter and oil change intervals have now been increased from the previous generation machines at 500 hours, to 1,000 hours, further reducing downtime and costs overall.

The engines meet the EU emissions regulations without the need for costly Exhaust Gas Recirculation (EGR) and Diesel Particulate Filter (DPF) cleaning intervals are extended up to 8,000 hours.

A massive air pre-cleaner filter was fitted on this example and an auto greasing system which is an optional fitting but, in my opinion, well worth investing in on a production machine like this.

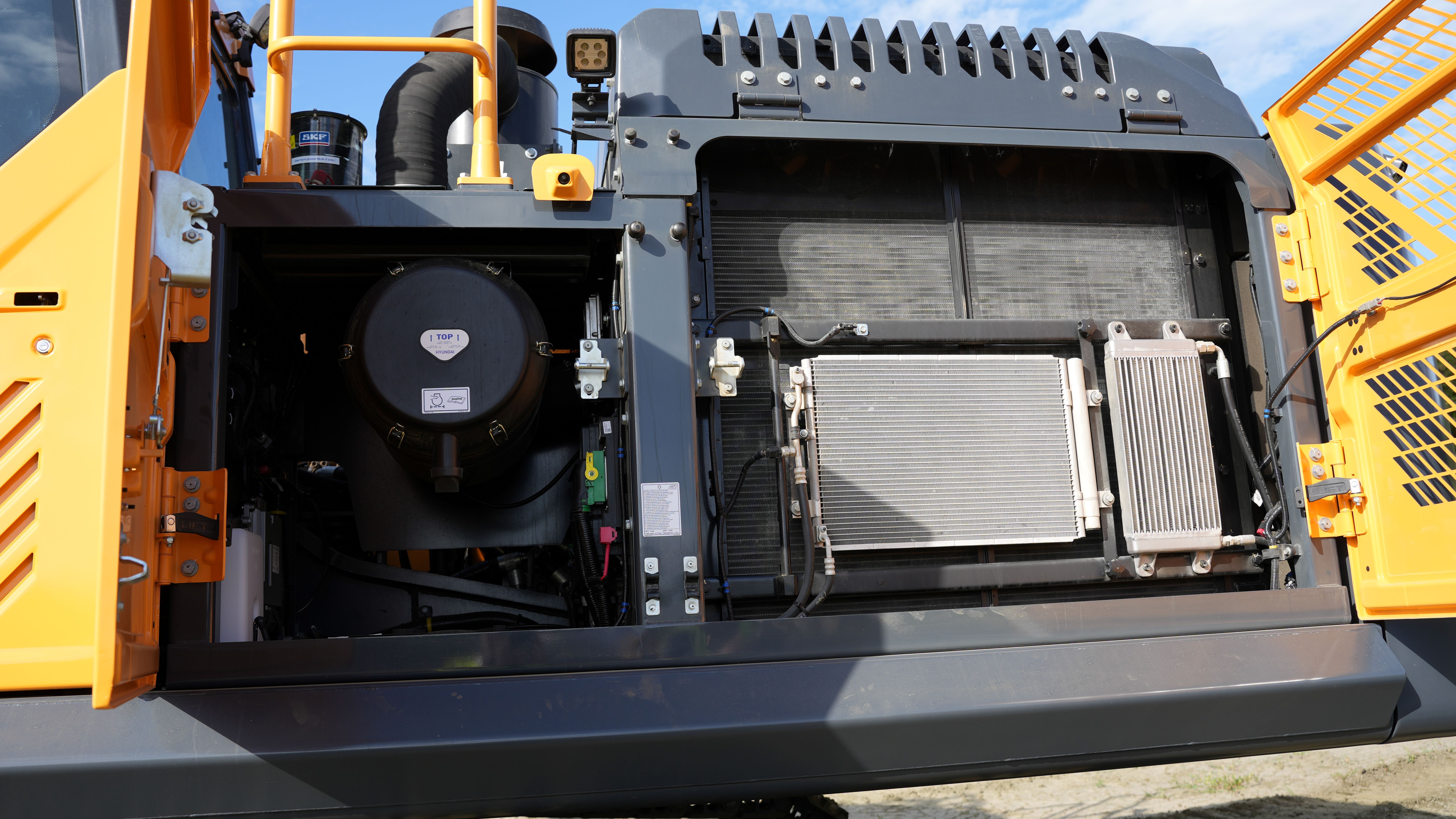

Coming back down to ground level and wandering around to the near side rear, we notice that some things remain the same as ever. Opening up the wide twin rear panel doors, reveals the usual fare, with the cooling packs and air conditioning radiator all easily accessible for cleaning of debris. In addition, the machine is fitted with a reversible fan which also assists with keeping to cooling packs clean of debris

Behind the panel closest to the cab, we find the air filter housing, 24-volt batteries, major isolation switch, windscreen washer bottle and other electrical components. There are also plastic covers on the batteries, so you could potentially store some cloth lifting strops in there too if needed.

To the offside rear, no surprise, its home to the main hydraulic pump, which are of the latest design from Rexroth. Both the HX360L and HX400L are the first Hyundai excavators to feature full electro-hydraulic (FEH) control of main pump flow and the individual control valves. This precise control of hydraulic output, through the use of EPOS (Electronic Pump Optimising System) and a virtual bleed-off valve, is said to improve responsiveness for the operator and reduces fuel consumption.

Also, in this area we find the engine oil and fuel filters, all easily accessible from ground level, or for someone of my stature, aided by a small box step, this is also home to the electric refuelling pump which is a standard fitment.

Sometimes it’s the little things that make a big difference, and on the HX360L, even the door opening handles and opening retaining latches have a feel of good quality about them.

On the undercarriage it’s the well proven and strong X-frame design, sitting on standard 600mm track pads, the track length on this model is 4958mm, with a track width of 3280mm. 9 lower track rollers are fitted with 2 top rollers, with 3 track guards to prevent de-tracking.

At the business end the HX360L has a boom length of 6500mm and a dipper arm length of 3200mm, according to Hyundai hydraulic pipework has been re-routed for improved protection against accidental damage, with trees for instance.

Climbing up into the extremely spacious Next Generation cab and my first impressions immediately were wow! We see a lot of cab interiors in the line of our duties and I often think just how can they improve from this, but it appears that Hyundai has once again taken it to another level.

Starting with the seat, this example was fitted with the optional ‘Comfort Pack’ premium leather seat, a heated and cooled, air suspension version that would not look amiss in a high-end Mercedes car, it’s totally luxurious to sit in, proving the support and comfort just where you need it, I would assume the standard fitment would be a cloth version.

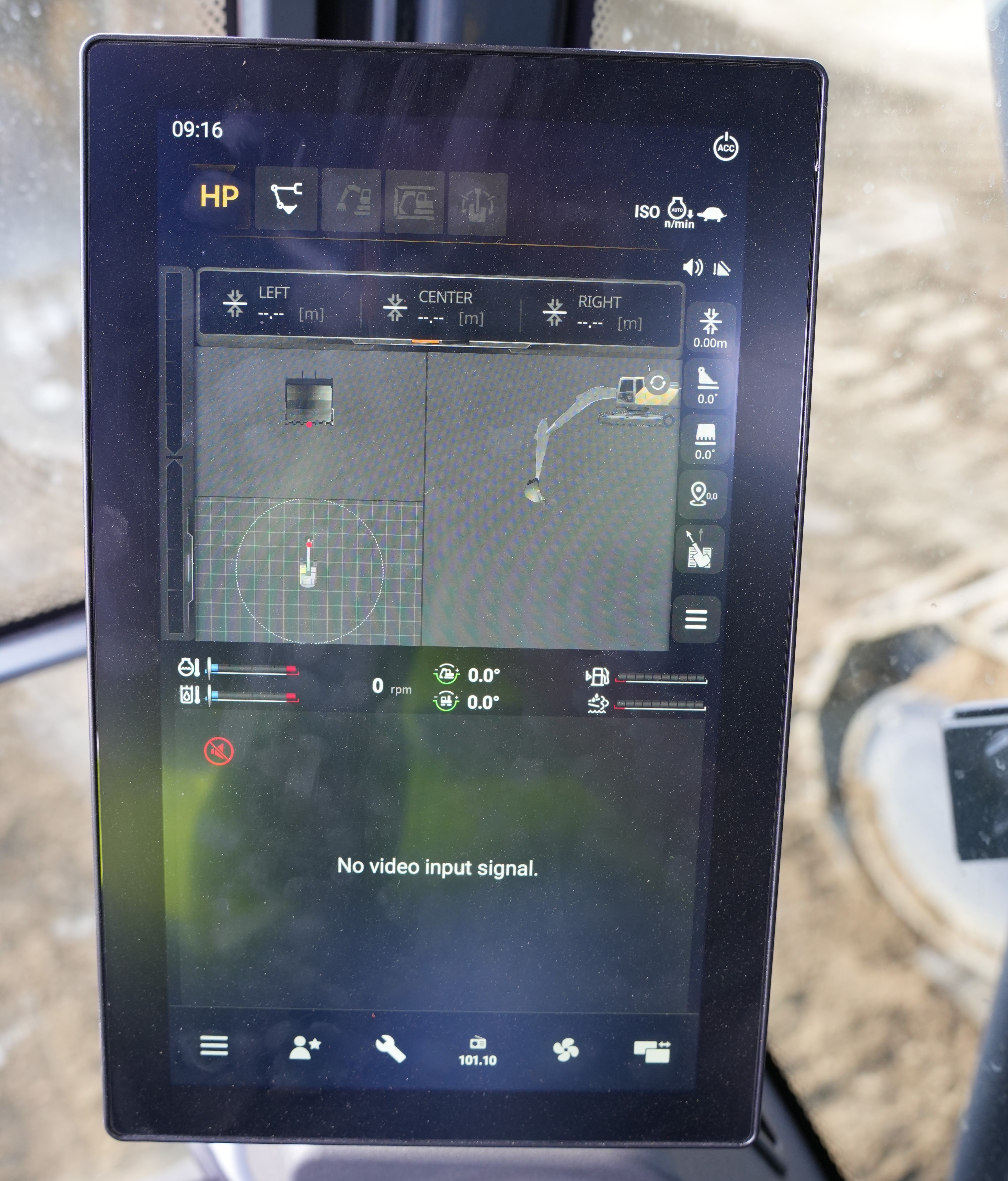

A 12.8” high-definition screen/monitor was fitted on this machine, but apparently production models will feature two of them. As per industry standard the monitors can display a host of different functions and allow the operator to personalise his own preferred machine settings.

Hyundai’s ever popular AAVM (Advanced Around View Monitoring) has been upgraded to SAVM (Smart Around View Monitoring). The old system featured four cameras located around the machine, but these new machines now boast six high resolution cameras, including three that are embedded into the counterweight. This new system is aided by artificial intelligence (AI) to detect and human presence encroaching into the machines operating radius, and displays them on the screen accompanied by an audible warning alarm.

There is a decent shelf behind the seat with cargo netting to retain the operators lunch bag in position, a cavernous cool box is located to the left to store cold drinks and perishable foods during those long hot days in the field, and a cubby hole to the right-hand side is always handy for bits and bobs, that us operators often accumulate, more often than not these days, polish and cleaning rags.

There is the usual arrangement of push button controls and dials on the right-hand console which have a quality look and feel to them and a push button start-stop feature to the right of the right-hand joystick. There is also a digital key option which allows the cabin to be opened and the engine started via a smart phone app, this digital key can be shared by up to six users.

On dark mornings operators will be delighted to see the welcome light strip which is incorporated into front console, lighting up the floor area and further improving safe access to the seat. Talking of the floor area, a newly designed mat is fitted which looks like it will be easier to sweep out at the end of a shift.

These machines can be supplied with optional new technology, like the option to have an automatic weighing function, that automatically measures the weight of the material inside the bucket, allowing for the precise calculation of truck loads and even volumes of material on site.

Another option is the Lift Assist feature offers operators a visual guide on the screen, divided into four visible quadrants, which display the safe zones for lifting a particular load ensuring maximum stability during a lifting operation.

The E-Boundary option, is another piece of technology that can be used to set a ceiling height, floor or wall boundary’s, similar to other manufacturers systems we have seen in recent years, this for example can be used to stop the machine slewing out into a live traffic lane for instance, or prevent accidental collisions with buildings or other structures when set to do so.

Also, as an option is the Radar Object Warning System which features three wide-angle radars which are capable of detecting people, objects or even other items of plant which may be approaching the machines working area, and offers an audible and visual alarm. The E-Stop function when activated can even slow down the machine and eventually stop it if it’s a dangerous situation. This is controlled by a four-corner beacon set up on the roof of the cab.

The machines come as standard with Hyundai’s Hi MATE telematic system and (EHM) Equipment Health Management technology ensures real-time monitoring of the working condition of the machine, ensuring the service department can predict any future problems ahead of a costly breakdown.

Taking to the seat I took a few moments to acquaint myself with my surroundings and to adjust the seat to my requirements. Starting involves pressing the start button and holding it down for a split second then the machine springs to life, I was initially greeted by a loud beeping noise, which was apparently the Advanced Detection System (ADS) telling me there were people nearby, although a considerable distance away, it was great to witness the technology at work.

However, I decided to isolate the function via the monitor and was just greeted by the purr of the six pot Hyundai diesel. A quick tweak of the throttle dial to up to the P position and the engine was up to full chat.

Releasing the isolation lever on my left-hand side and with a tug on the right-hand joystick the boom powered up and we were away. Climbing up on a heap of previously excavated material I proceeded to dig out more from the hole. The soil here was extremely sandy and had probably have been dug over 1000 times before, so it presented no challenge to the big 36-tonner even with its biggest bucket on board.

However, this soil was damp and pretty heavy so over the side with a full to the brim bucket, you knew you had it out there, but try a I may to unsettle the machine it largely remained planted.

I would best describe the pace of the HX360L as steady and certainly lively enough, but I still felt it needed a bit more, so I opted to press the HP button, the change in both speed and power was I felt quite dramatic and I quickly warmed to the new performance level, talking of warmth, by now the early morning sun was piercing through the glass so after a bit of navigating I found the air-conditioning/blower selection screen, which by then was a welcome relief!

The machine features Hyundai’s new FEH (Fully Electrohydraulic) which they say improves fuel consumption by controlling the flow rate via an EPOS (Electric Power Optimising System).

Hyundai state that FEH controls send an electrical signal to the control valves, delivering faster, more accurate operation of hydraulic functions. There is no back pressure or energy loss, as the exact oil flow and pressure is delivered when required, resulting in a fuel efficiency improvement of up to 8% over hydraulic servo levers.

Personally, I’m not a fan of electro hydraulic controls, they kind of feel numb to me, it’s the little things like trying to fire some material towards yourself with a quick jerk of the dipper arm lever, it just doesn’t seem as effective with electro hydraulics as it used to with traditional servo controls.

I also found fine grading a little bit tricky as there always seemed to be a dip at the transition point of bringing in the dipper, however, one would get used to it after a day or so of constant operating. In all other aspects the machine was super smooth, had impressive power and performance.

I especially liked the joystick-controlled tracking, with just a click of an index finger on the left-hand control lever, I could travel and steer the tracks with that one lever, a feature that would be very useful on site.

Here below is long standing Hyundai Product Management Team Leader Gert Peeters to tell us more.